Select a 3D visual sensor and divide the pre processed image data of grinding cracks in automotive gears into gear bodies, automotive gear auxiliaries, and background renderings to obtain the histogram peak value of the image. The pixel threshold range is set based on the histogram peak similarity of the image, and the shape, density, and area characteristics of the automotive gear grinding crack image are extracted using the image contour recognition technology of the two-dimensional laser radar point cloud.

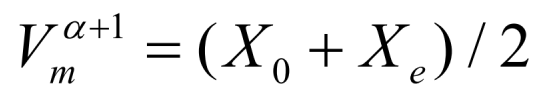

After filtering, noise reduction, and graying processing, the image data of automotive gear grinding cracks has been comprehensively optimized. Before entering the image feature extraction process, it is necessary to compare the histogram peak similarity of each image. Based on the comparison results and the image thresholding principle, the automotive gear grinding crack image is divided into automotive gear bodies with different thresholds through 3D visual sensors Thresholds of three major pixel points for automotive gear accessories and background renderings. The formula for calculating the histogram peak similarity is as follows:

Where: X0 is the maximum value of image histogram similarity; Xe is the minimum value of image histogram similarity.

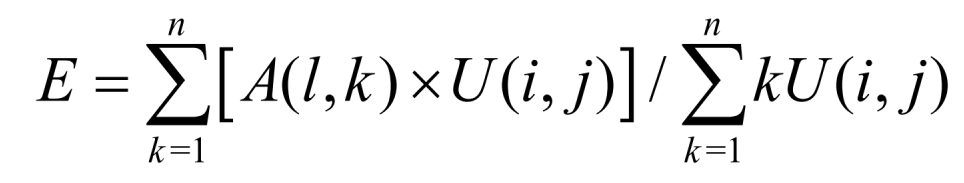

The principle of image thresholding is to divide the entire data of the grinding crack image of an automobile gear into pixel threshold regions that are easy to extract features by setting different thresholds. Collect the histogram peak similarity comparison results of automotive gear grinding crack images as the starting data for image thresholding. In this dataset, the threshold segmentation method of 3D visual sensors is used, and the expression is as follows:

Where: is the similarity of the image; U is the partition node; K is the threshold interval dimension after segmentation of the 3D visual sensor; N is the maximum value of the pixel threshold interval dimension.