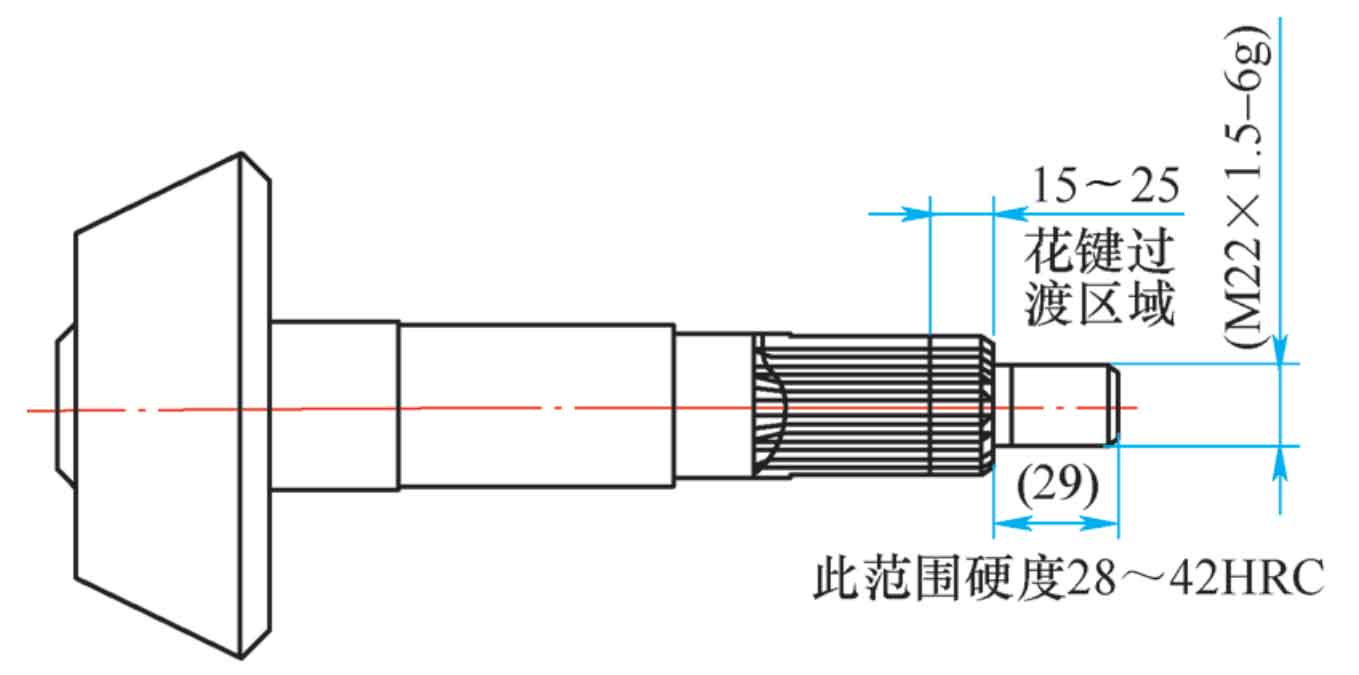

According to the above optimization results, after technical communication with the customer and approval, the technical requirements for adjusting the hardness of the driving spiral bevel gear are as follows: the hardness at the external thread is 28 ~ 42hrc, the evaluation area is 5 ~ 15mm away from the end face of the external spline, and the hardness is 42 ~ 56hrc, while the 15 ~ 25mm transition area is only for reference, as shown in the figure.

After this induction annealing process, M22 × The external thread with a total length of 29mm at 1.5-6g shall be inspected and treated. Insert the die into the thread of the driving spiral bevel gear, pay attention to the perpendicularity with the axis of the bevel gear, rotate the die evenly, and use the thread ring gauge to detect the thread after tooth trimming to ensure the sequence of qualified parts. After the above measures have been cured, the abnormal fracture at the R corner of the connection transition between external thread and external spline has not occurred again. The road test has passed. At present, mass production has been realized.