In order to study the influence law of tooth top fillet r on the forming of spur cylindrical gear, the numerical simulation is carried out when the tooth top fillet R is 1mm, 1.2mm, 1.4mm, 1.6mm and 1.8mm respectively. The other process parameters are sizing belt length L = 5mm and die angle α= 45 ° and splitting angle thickness t = 3.0mm.

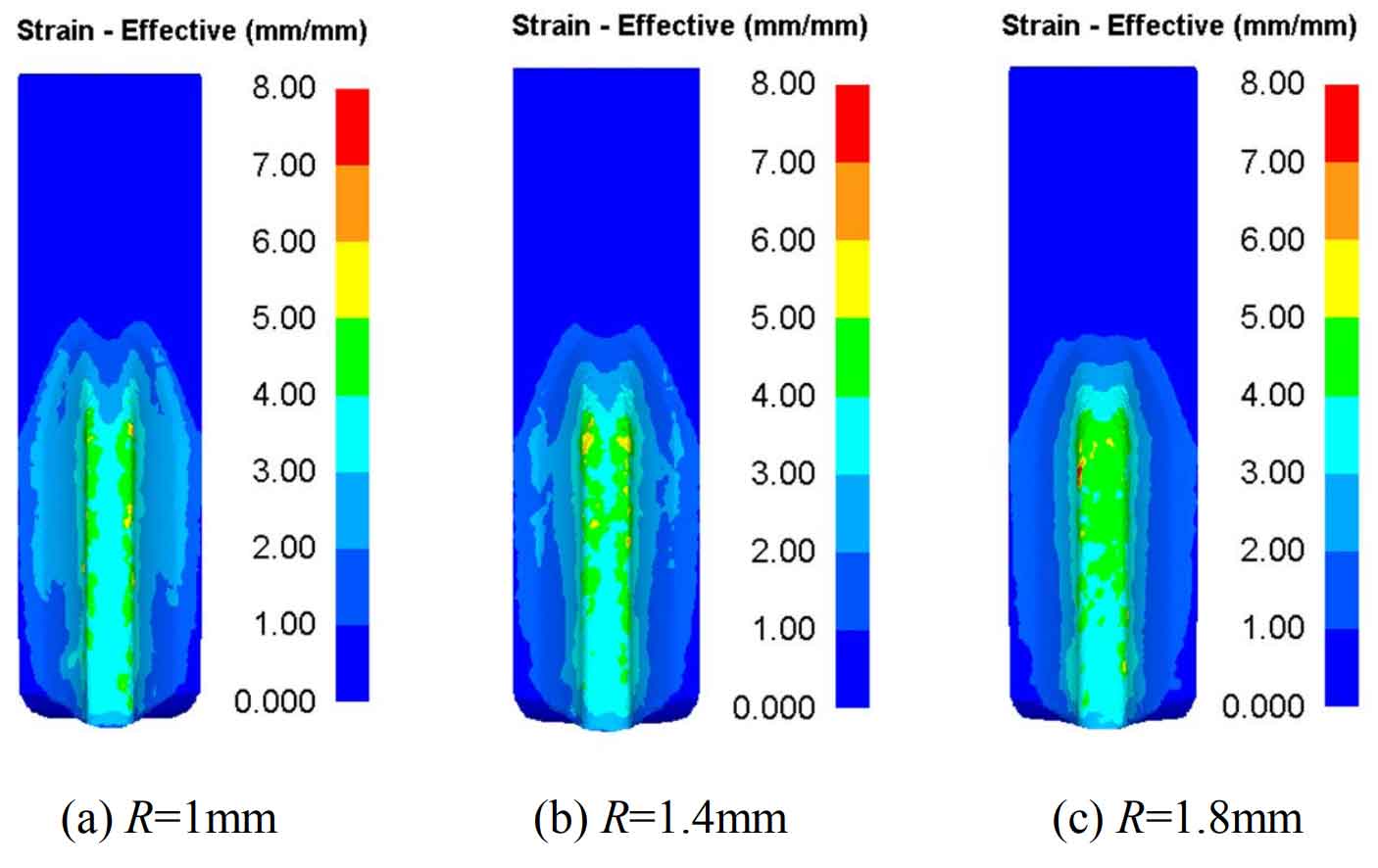

Fig. 1 is the cloud diagram of equal effect variation distribution of cold extruded spur gears with different addendum fillets. It can be seen from the figure that the effects of extrusion from tooth top to tooth root gradually increase, and with the gradual increase of tooth top fillet of tooth profile die, the effects of cold extrusion spur gear tooth root increase, and the distribution of tooth surface effects tends to be uniform. Therefore, on the premise of meeting the use and design requirements, it is necessary to appropriately increase the tooth top fillet of the tooth concave die, improve the metal flow and improve the forming quality of cold extruded spur gear.

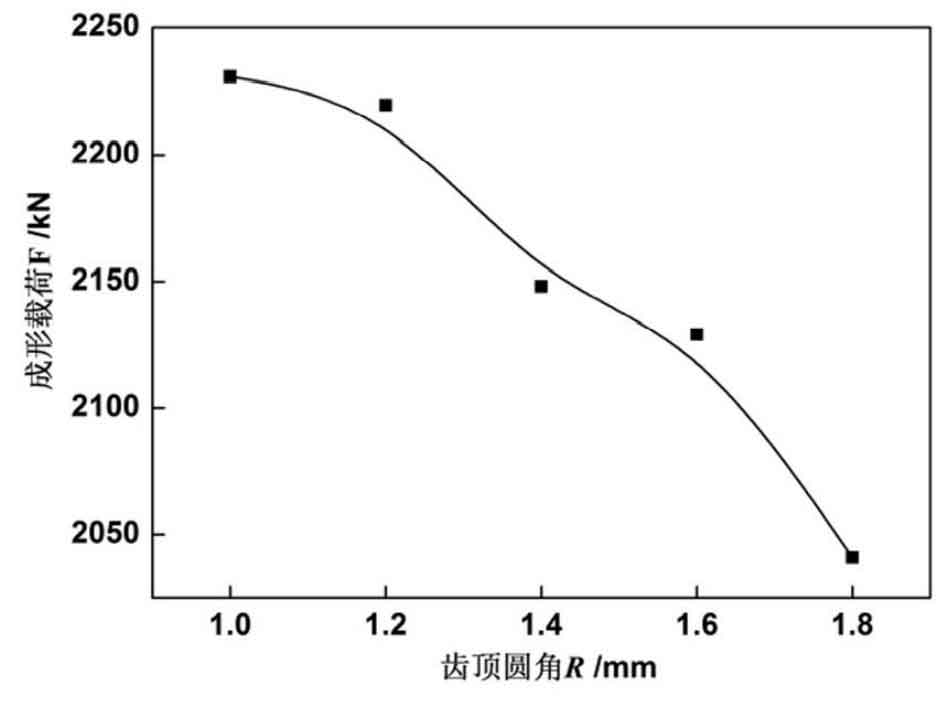

Fig. 2 shows the influence law of different addendum fillets on cold extrusion forming load. The forming load decreases with the increase of addendum fillets. To sum up, on the premise of meeting the design and use requirements, it is necessary to appropriately increase the tooth top fillet of the tooth shaped female die, improve the metal flow in the cold extrusion process, improve the forming quality of the extrusion, reduce the forming load and prolong the service life of the die.