The table lists the precision adjustment values of the processing parameters of the spiral bevel gear pinion. The accuracy of one machining parameter is changed every time, and its influence on the results of tooth contact analysis is studied.

| Serial number | a | b | c | d | e |

| Vertical wheel position /mm | 38.1028 | 38.1328 | 38.1528 | 38.1728 | 38.2028 |

| Radial tool position /mm | 147.7426 | 147.7726 | 147.7926 | 147.8126 | 147.8426 |

| Angular tool position / ° | 68.80 | 69 | 69.12 | 69.24 | 69.44 |

| Axial wheel position /mm | 3.5816 | 3.6116 | 3.6316 | 3.6516 | 3.6816 |

| Bed /mm | -1.2594 | -1.2294 | -1.2094 | -1.1894 | -1.1594 |

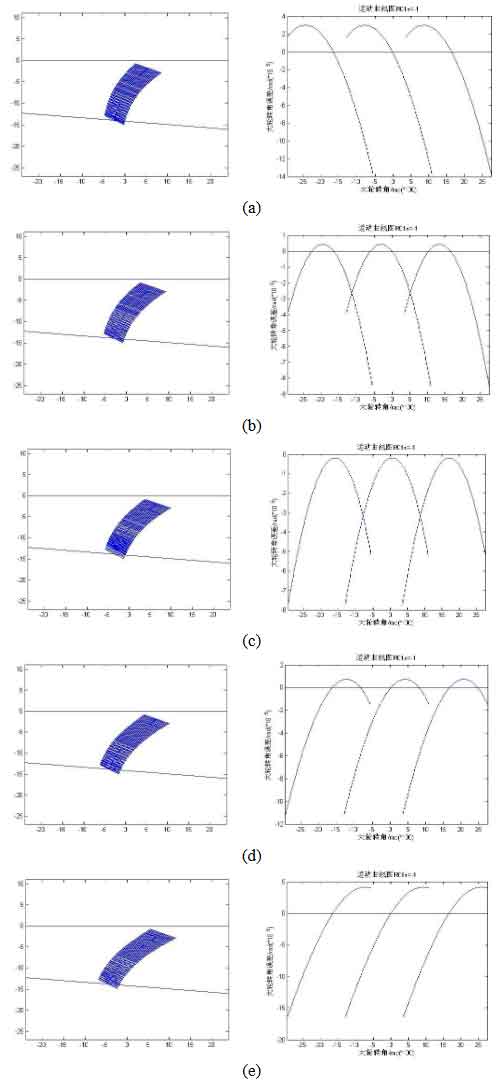

According to the radial tool position adjustment values in the above table, the TCA analysis is carried out on the spiral bevel gear pair, and the results are shown in the figure.

By analyzing the figures in the figure, it can be concluded that the adjustment accuracy of the radial tool position of the spiral bevel gear pinion has little effect on the tooth surface contact area, mainly on the motion curve. By observing the change of the slope k of the motion curve when the abscissa is 0, when the radial tool position of the spiral bevel gear pinion is greater than the theoretical value, the slope k of the motion curve when the abscissa is 0>0, and the contact area moves to the tooth top; When the radial tool position of the spiral bevel gear pinion is less than the theoretical value, the slope k of the motion curve when the abscissa is 0 is less than 0, and the contact area moves to the tooth root.

The accuracy of the adjustment values of the angular cutter position, axial wheel position and bed position in the machining of spiral bevel gears has little effect on the tooth surface contact, and is not a sensitive parameter affecting the tooth surface contact. The accuracy of the adjustment values of the vertical wheel position, angular cutter position, axial wheel position and bed position during the small wheel machining has little influence on the results of the tooth surface contact, and is not a sensitive parameter affecting the tooth surface contact. Therefore, in the process of adjusting the parameters of the spiral bevel gear machine tool, it is necessary to try to improve the adjustment accuracy of the vertical wheel position, radial tool position of the large spiral bevel gear wheel and the radial tool position of the small spiral bevel gear wheel, so as to make the meshing characteristics of the spiral bevel gear processed by the machine tool as close as possible to the TCA results.