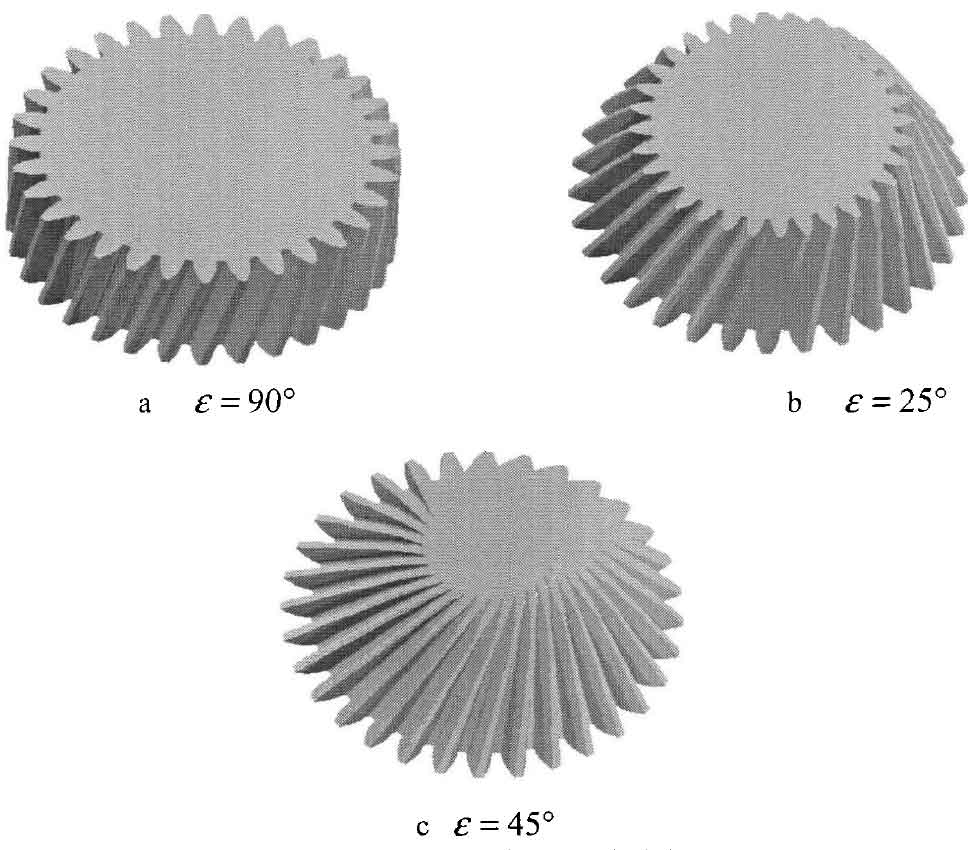

When the module, number of teeth, helix angle and process parameters of helical gear are consistent, three groups of different tooth cone angles are selected ε= 0°、 ε= 25°、 ε= 45 ° to analyze the influence of spiral gear tooth cone angle on helical gear forming. Where, when the tooth cone angle ε= At 0 °, the gear is a helical cylindrical gear; Tooth angle ε= 25°、 ε= At 45 °, the gear is a spiral bevel gear.

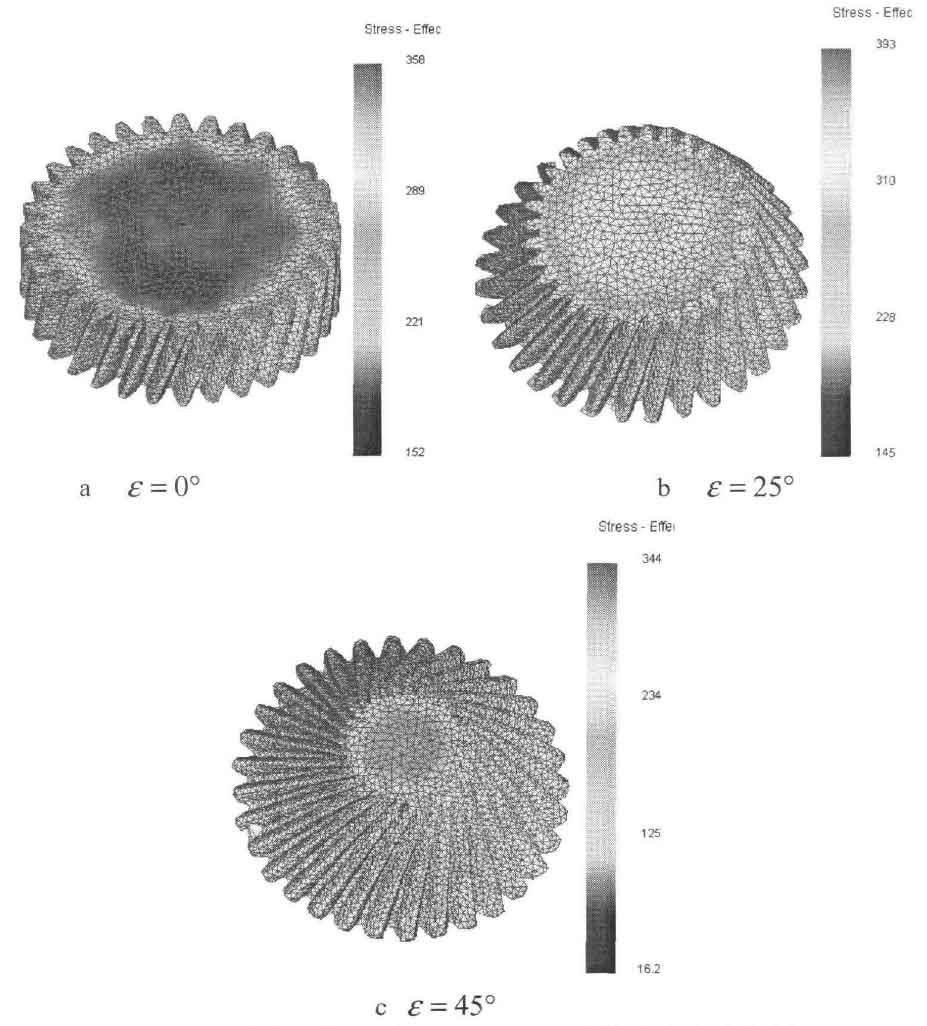

Cone angle ε= 0°、 ε= 25°、 ε= The equal effect force distribution diagram when the reduction of 45 ° helical gear is 100% is shown in Figure 2. When ε= At 0 °, the gear is a helical cylindrical gear, and its maximum equivalent force is at the top and corner of the tooth, with 240mpa. When ε= At 25 °, the gear is a spiral bevel gear, and its maximum equivalent force is located at the tooth corner of the small end face of the spiral bevel gear, with 310mpa, and the stress at the top of the tooth is 220MPa. When ε= At 45 °, the gear is a spiral bevel gear, and the maximum equivalent force is also at the tooth corner of the small end face of the spiral bevel gear, with 280mpa, and the stress at the top of the tooth is about 220MPa. The spiral bevel gear is an umbrella. Under the same load, the equal effect force value of the small end face will be large due to the small contact area. Therefore, in the closed die forging of the spiral bevel gear, the maximum equivalent stress is at the tooth corner of the small end face of the helical gear.

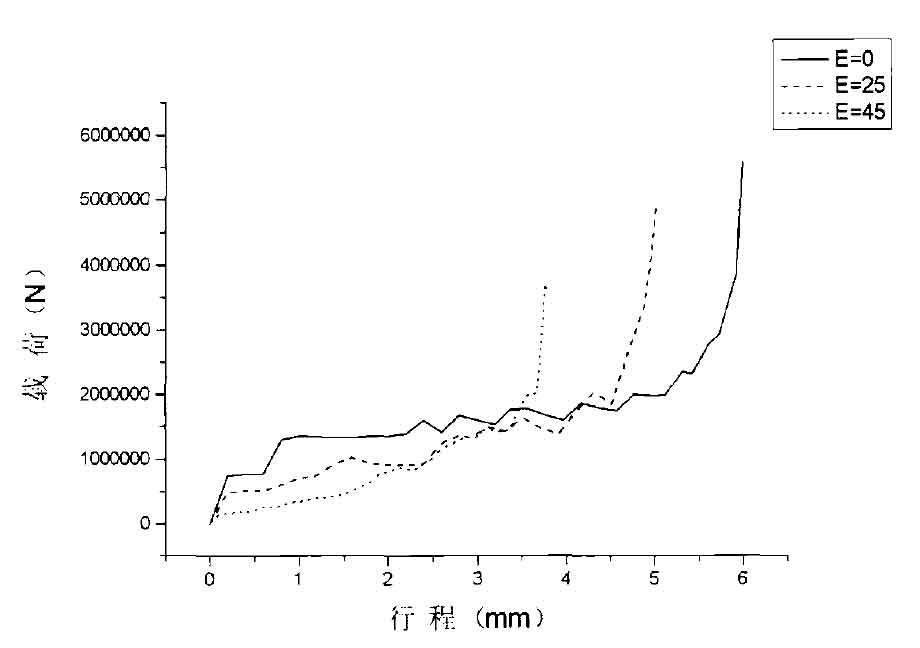

Figure 3 shows three sets of cone angles ε= 0°、 ε= 25°、 ε= Load stroke curve of 45 ° helical gear in closed die forging. When cone angle ε= At 0 °, the final load value of helical gear is 5800kn. When cone angle ε= At 25 °, the load value is 4900kn. When cone angle ε= At 45 °, the final load value is 3800kn. It can be seen from the figure that the load decreases with the increase of cone angle. Cone angle ε= At 0 °, the helical gear is mainly formed by filling the teeth with metal in the radial direction. With the increase of the cone angle, the metal not only fills the tooth cavity in the radial direction, but also fills the tooth cavity in the axial direction. The larger the cone angle is, the more the tooth cavity is filled in the axial direction, the easier the helical gear is to be formed.