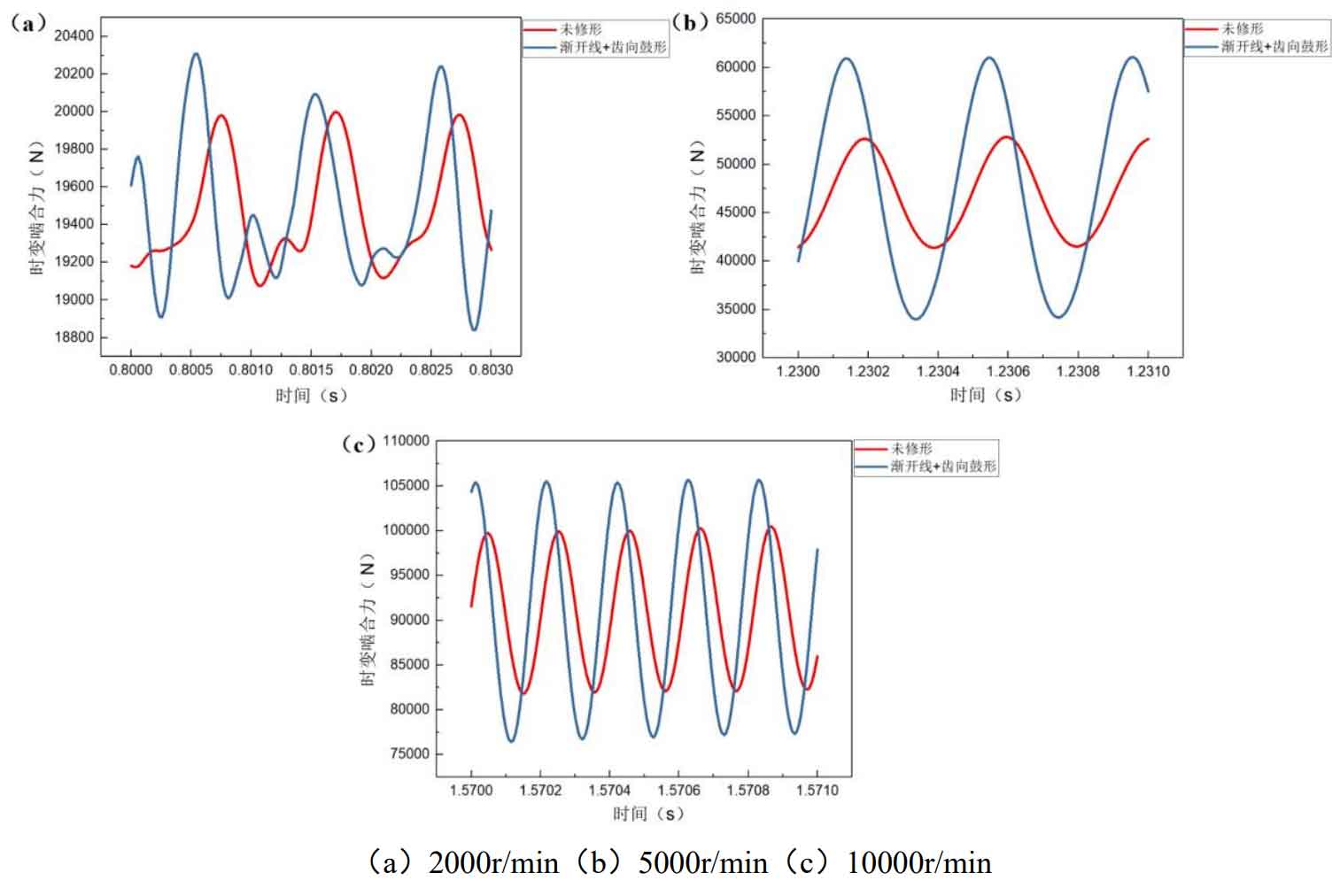

(1) The influence of compound optimization modification scheme of top involute and tooth direction drum of long tooth profile of large gear on time-varying meshing force of helical gear

The optimization scheme of the composite modification of the top involute of the long tooth profile of the big gear+the tooth direction drum shape is that the modification amount of the driving gear is 0 μ m. The crown involute of the long tooth profile of the driven gear and the crown modification of the tooth direction are all 3 μ m。 Figure 1 shows the time varying meshing force curve of the helical gear pair before and after the long tooth profile tooth tip involute+tooth direction drum composite modification of the big gear under different speeds. Obviously, the modification effect of this scheme is not good. It not only increases the peak values of the time-varying meshing force of helical gears at low, medium and high speeds to 20306.797N, 61036.934N and 105683.086N respectively, but also makes the meshing impact more serious.

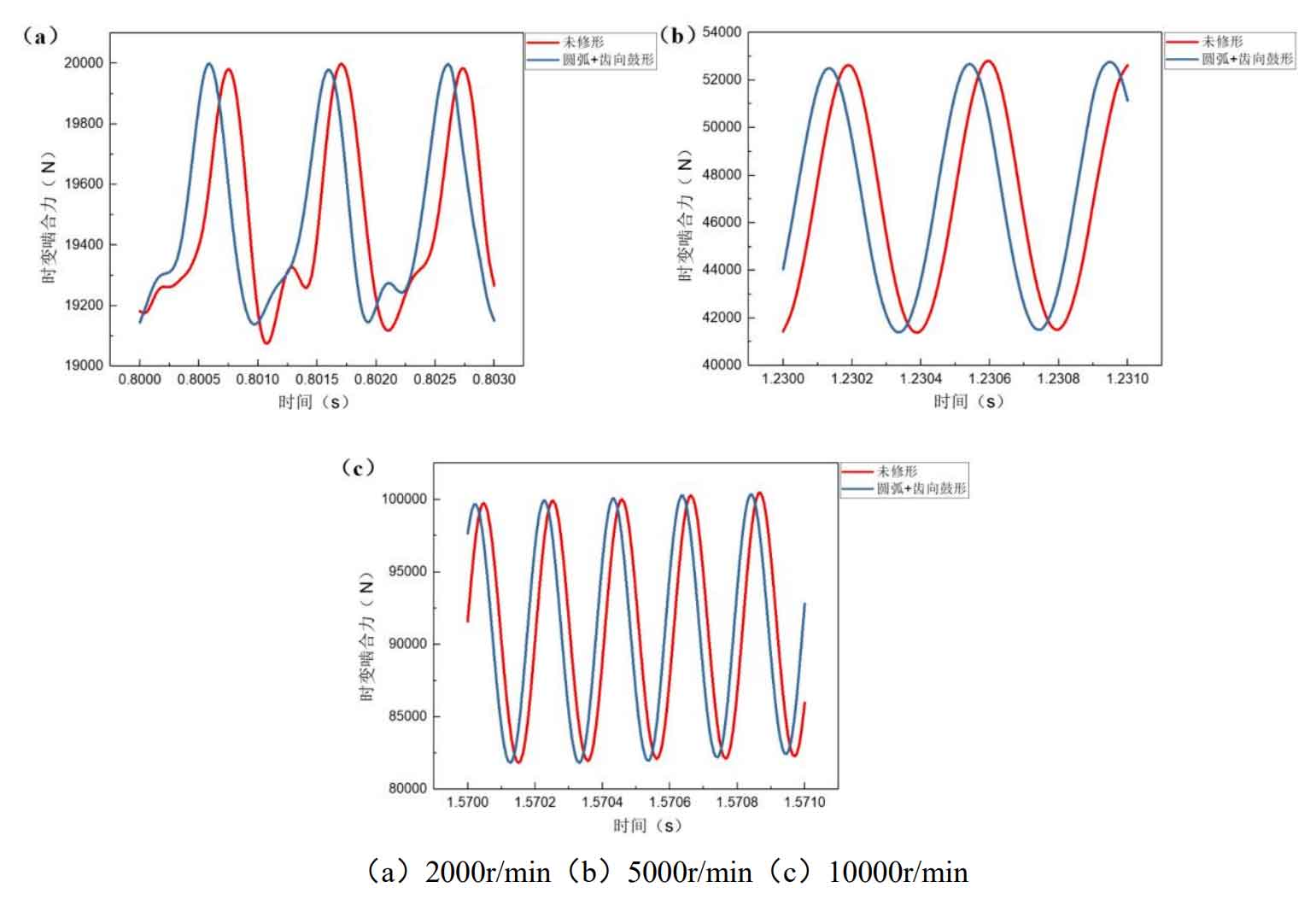

(2) The influence of compound optimization modification scheme of addendum arc and tooth direction drum for long tooth profile of large gear on time-varying meshing force of helical gear

The optimization scheme of the composite modification of the long tooth profile of the big gear tooth top arc+tooth direction drum shape is the modification amount of the driving gear 0 μ m. The crown involute of the long tooth profile of the driven gear and the crown modification of the tooth direction are all 3 μ m。 Figure 2 shows the time varying meshing force curve of the helical gear pair before and after the composite modification of the top arc of the long tooth profile of the big gear and the drum in the tooth direction at different speeds. It can be seen from the figure that the modification scheme is not ideal in terms of reducing the time-varying meshing force. The peak values of the time-varying meshing force of helical gears at low, medium and high speeds are 20000.129N, 52758.305N and 100341.289N respectively.

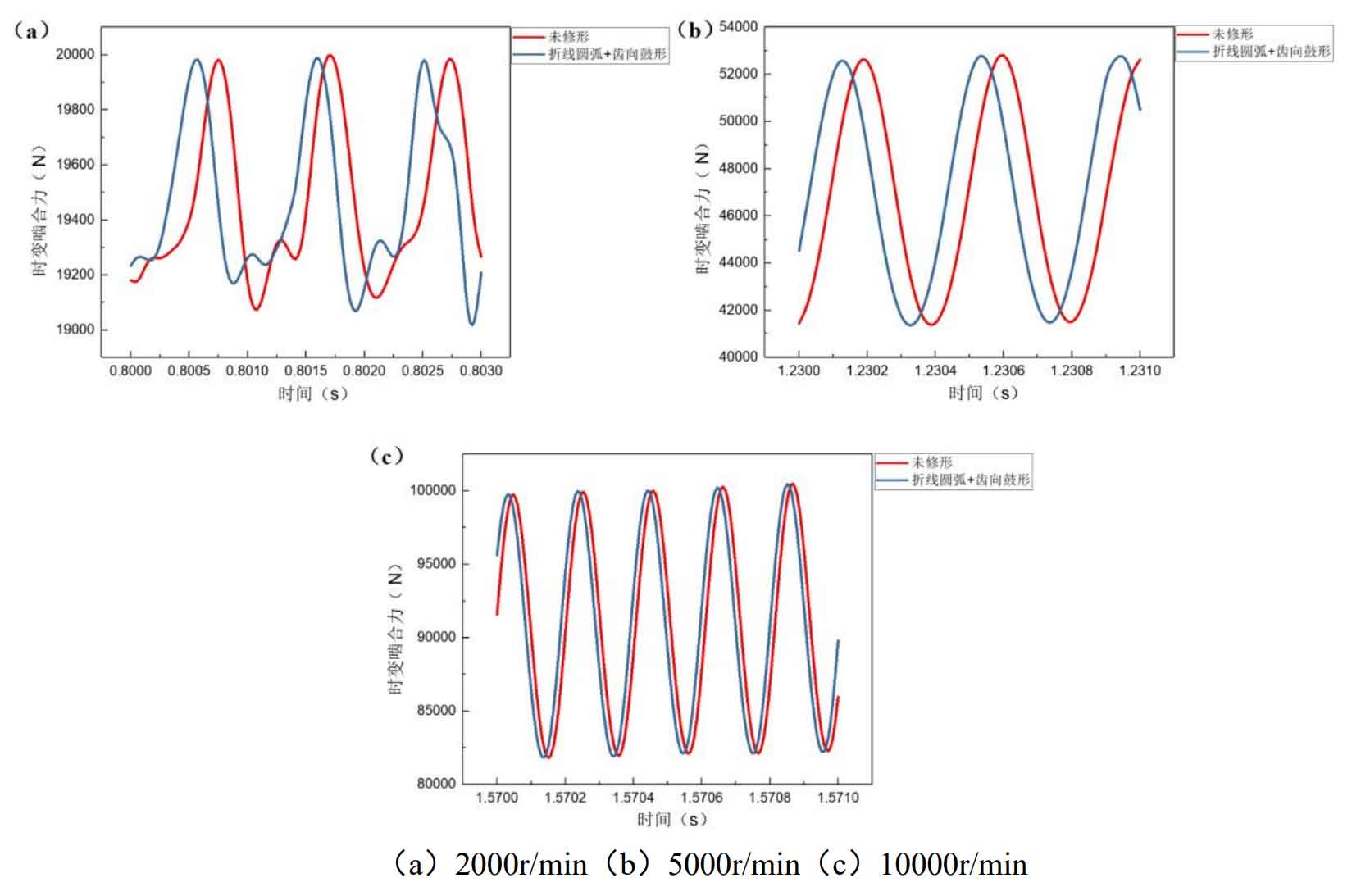

(3) The Influence of Compound Optimization Modification Scheme of Long Tooth Profile Tooth Crest Arc+Tooth Direction Drum of Large Gear on Time varying Engagement Force of Helical Gear

The optimization scheme of the composite modification of the long tooth profile of the big gear, the top broken line arc and the tooth direction drum, is that the modification amount of the driving gear is 0 μ m. The crown involute of the long tooth profile of the driven gear and the crown modification of the tooth direction are all 3 μ m。 Figure 3 shows the time varying meshing force curve of the helical gear pair before and after the composite modification of the long tooth profile of the big gear, the tooth top fold line arc and the tooth direction drum. It can be seen from the figure that although the time-varying meshing force of the helical gear pair after optimization and modification of the scheme has decreased, and the peak meshing force under low, medium and high speed conditions are respectively 19988.063N, 52742.453N and 100395.117N, which are 11.05N, 51.824N and 89.203N lower than those without modification, the curves are too tortuous, which is not conducive to relieving the meshing impact between helical gear pairs.

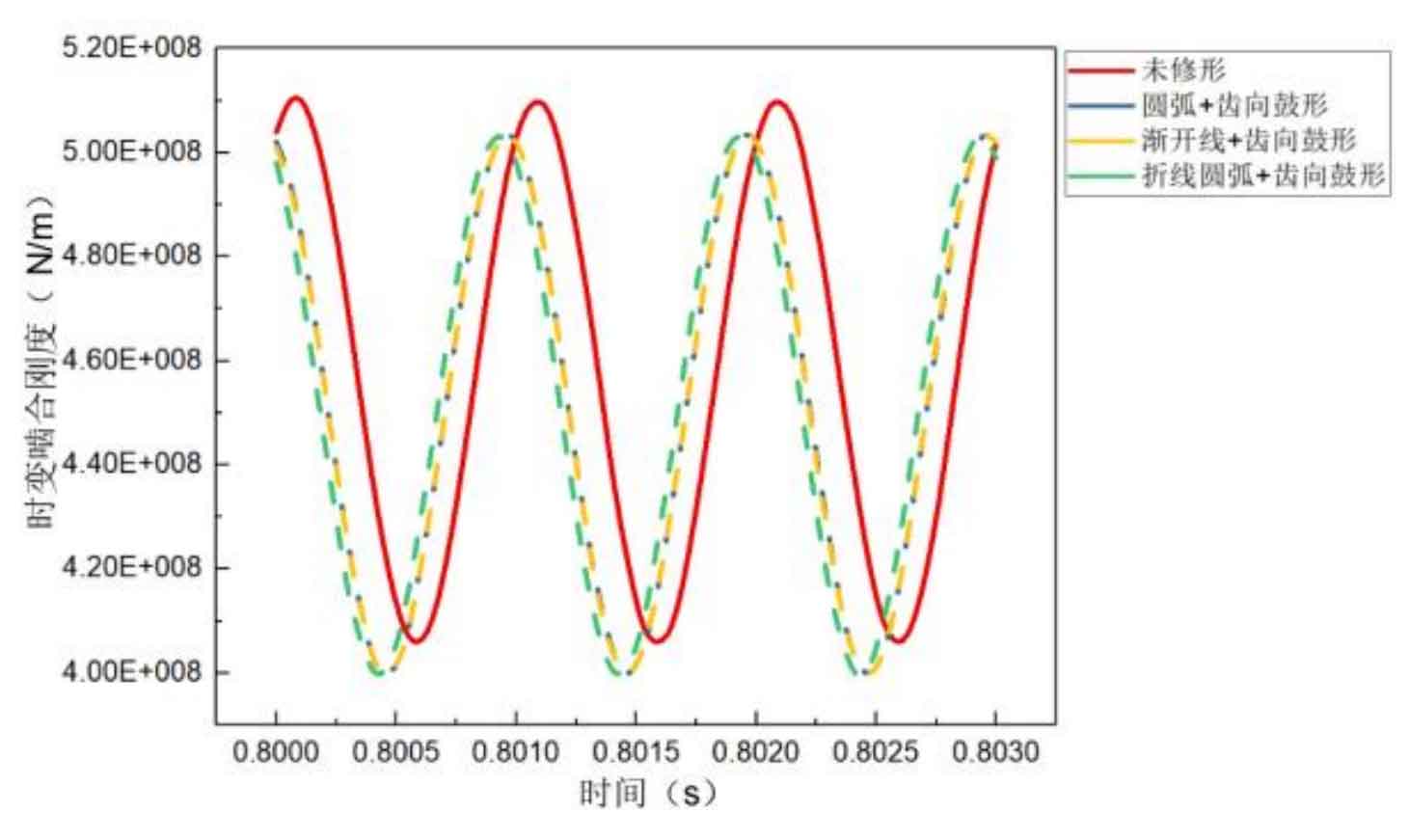

(4) Influence of compound optimization modification of large gears on time-varying meshing stiffness of helical gears

Figure 4 shows the time-varying meshing stiffness curves of the helical gear pair before and after the composite optimization modification of the big gear. Although the composite optimization modification scheme adopted for the driven gear (big gear) is different, it can be seen that the time-varying meshing stiffness of the modified helical gear decreases significantly, and its fluctuation range is 4 × 108N/m~5.03 × 108N/m, a decrease of 1.3%.

To sum up, only the composite optimization modification of the big gear of the helical gear pair can slightly reduce the stiffness excitation, but it cannot effectively improve the meshing impact between helical gear pairs. In engineering practice, the cost of adding a tooth profile or tooth direction modification process is often extremely expensive. Therefore, on the premise that the optimization scheme of single modification mode can meet the requirements of helical gear use, it is generally not recommended to modify the tooth profile and tooth direction in a composite way. All the composite optimization modification schemes are omitted here.