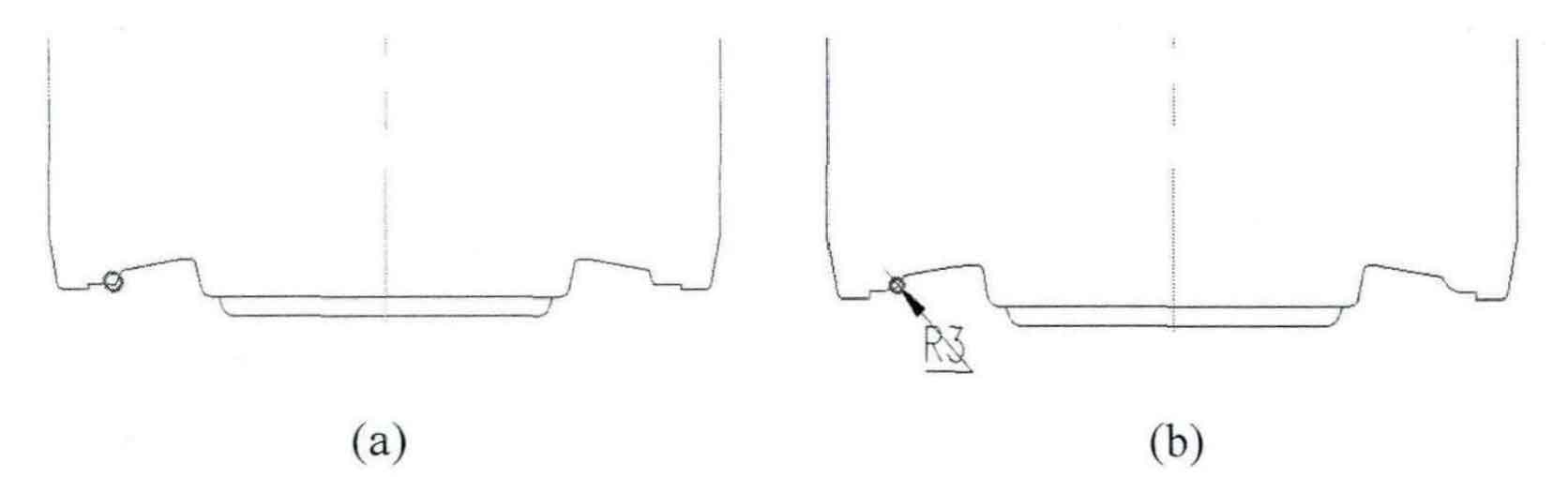

Through the stress-strain analysis and temperature analysis of spiral bevel gear blank after hot forging, we know that it is difficult for metal materials to flow at the two steps of the die, one of which is the step between the outside of spiral bevel gear blank and flash. Therefore, the influence of die structure on the forming effect of spiral bevel gear blank is studied by turning a fillet with a radius of 3mm at the connection between the inner cavity of the upper die and the flash groove. This chamfer will not affect the size of the forging body. The two-dimensional partial view of the upper die before and after chamfering is shown in Figure 1.

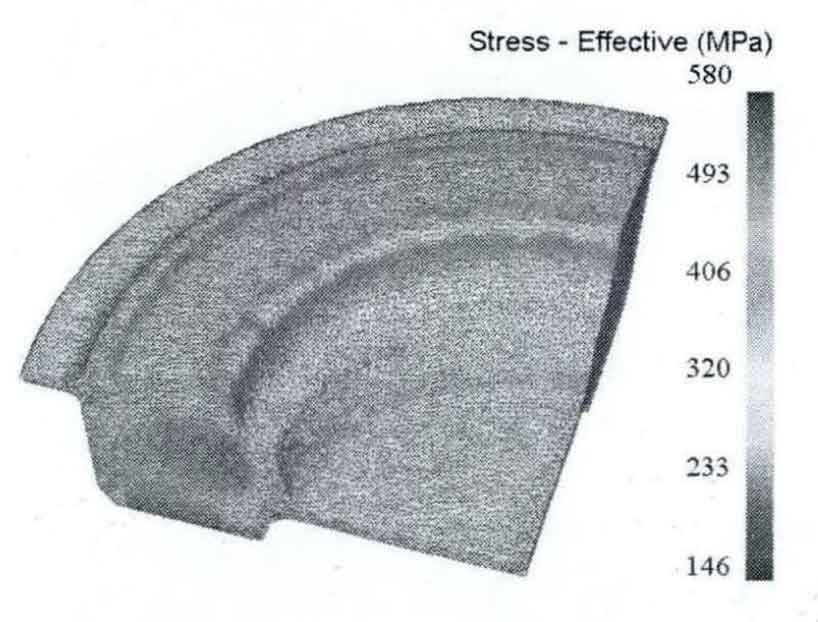

1.Stress analysis after die improvement

The equivalent stress distribution during final forging of spiral bevel gear blank after die improvement is shown in Figure 2. The maximum stress of the forging after the improvement of the die is 580mpa. The large stress occurs at the steps of the outer side and flash of the spiral bevel gear blank, and the stress at the steps of the inner side and the concave thin layer is also large. The stress at the step between the outer side and the flash of the spiral bevel gear blank is 310-580mpa, the stress at the step between the inner side and the concave thin layer is 300-420mpa, the stress at the flash and the concave thin layer is 270-330mpa, and the stress at the main body of the spiral bevel gear blank is 146-330mpa. The maximum stress is lower than that before the improvement, and the overall stress value is also lower than that before the improvement by 116mpa. The decrease of stress value indicates that the metal flow has been improved after the improvement of die structure.

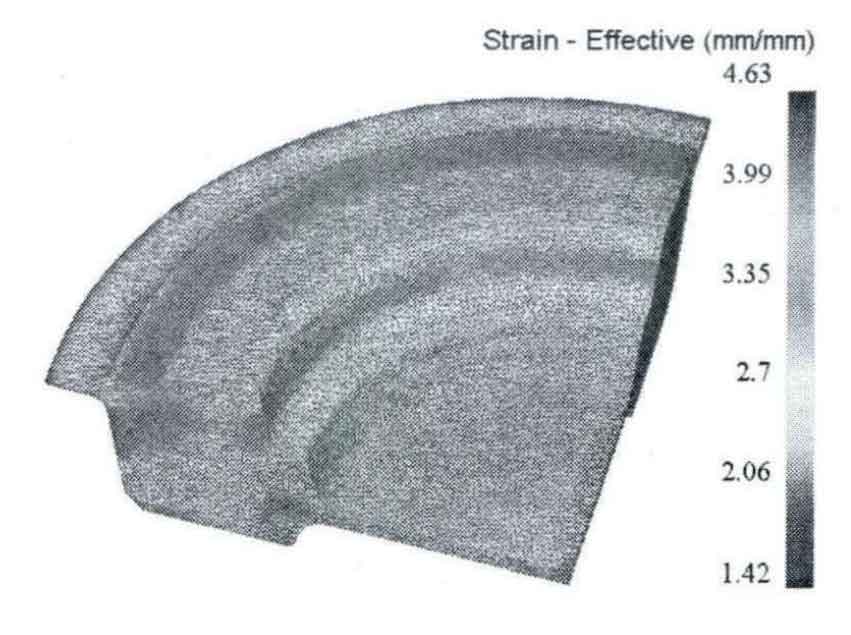

2.Strain analysis after die improvement

The distribution of equivalent strain during final forging of spiral bevel gear blank after die improvement is shown in Figure 3. The maximum strain of forging after die improvement is 4.63. Large strain also occurs at the steps of the outer side and flash of the spiral bevel gear blank and the steps of the inner side and concave thin layer. The strain at the step between the outside of the spiral bevel gear blank and the flash is between 2.98-4.28, the strain at the step between the inside and the concave thin layer is between 3.20-4.63, the strain at the flash and the concave thin layer is between 1.60-3.32, and the strain of the main body of the spiral bevel gear blank is between 1.42-3.10. The maximum strain is 0.97 lower than that before improvement, and the overall strain value is also lower than that before improvement. The decrease of strain value indicates that the metal flow has been improved after the improvement of die structure.

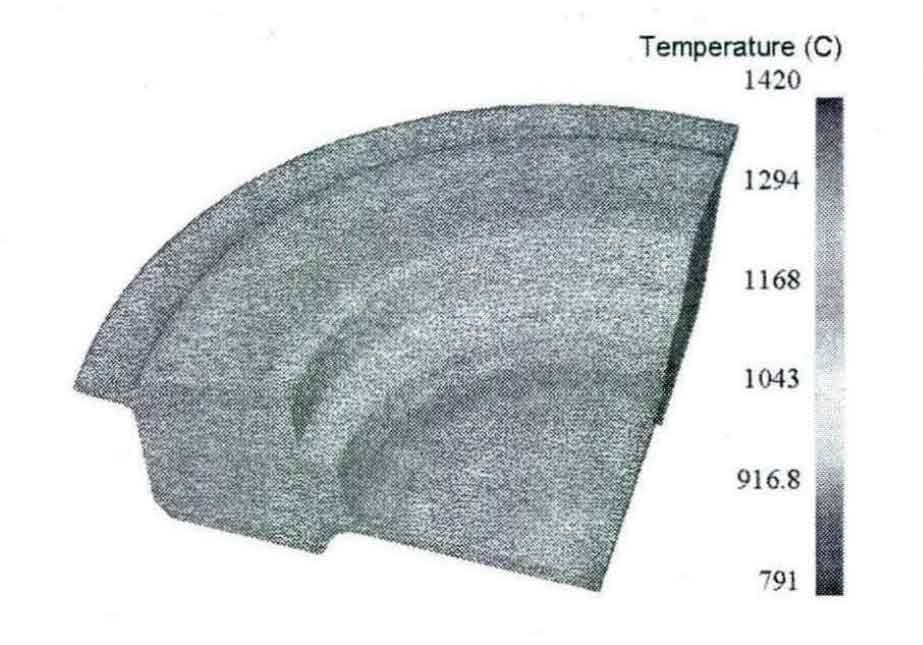

3.Temperature analysis after mold improvement

The temperature distribution during final forging of spiral bevel gear blank after die improvement is shown in Figure 4. The maximum temperature of forging after die improvement is 1420 ° C. The high temperature also occurs at the steps of the outer side and flash of the spiral bevel gear blank and the steps of the inner side and the concave thin layer. The maximum temperature is 75 ° C lower than that before the improvement, and the overall temperature is also reduced. This also shows that the flow of metal has been improved.

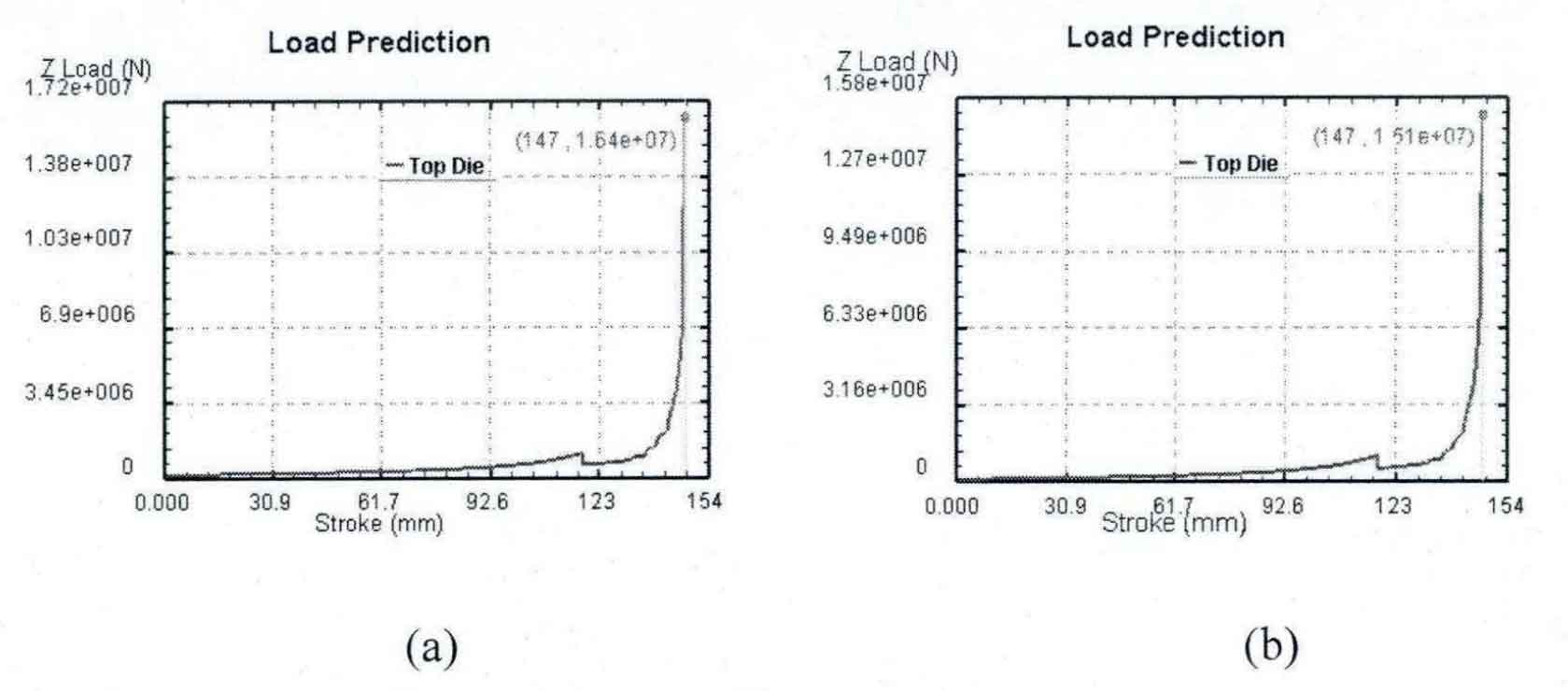

4.Analysis of stroke load curve before and after die improvement

The stroke load curve of the total forging process before and after the improvement of the spiral bevel gear die is shown in Figure 5. The forming load of final forging before improvement is 16.4t and 15.1t after improvement, which is 1.3t lower than that before improvement. This shows that the reasonable improvement of the die structure of spiral bevel gear can effectively reduce the forming load.

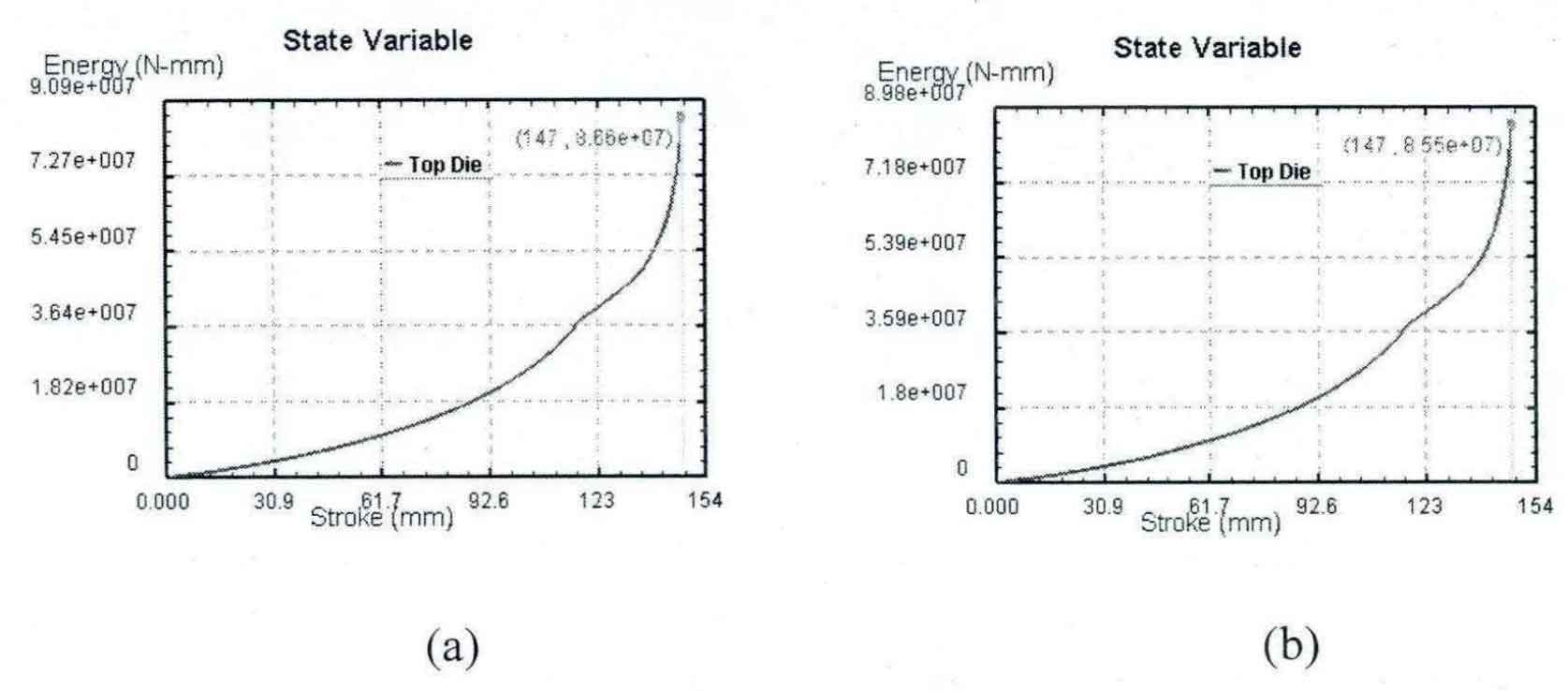

5.Analysis of stroke energy consumption curve before and after die improvement

The stroke energy consumption curve of spiral bevel gear die before and after improvement is shown in Figure 6. The energy consumption of final forging before improvement is 86.6kj, and that of final forging after improvement is 85.5kj, which is 1.1kj less than that before improvement. Therefore, reasonable improvement of the die structure of spiral bevel gear can also effectively reduce forging energy consumption.

To sum up, the die structure of spiral bevel gear has an important impact on the forging process. Reasonably improving the die structure of spiral bevel gear can effectively improve the metal flow in the forging process, reduce stress, strain, temperature and forming load, reduce forging energy consumption and improve the quality of spiral bevel gear forgings.