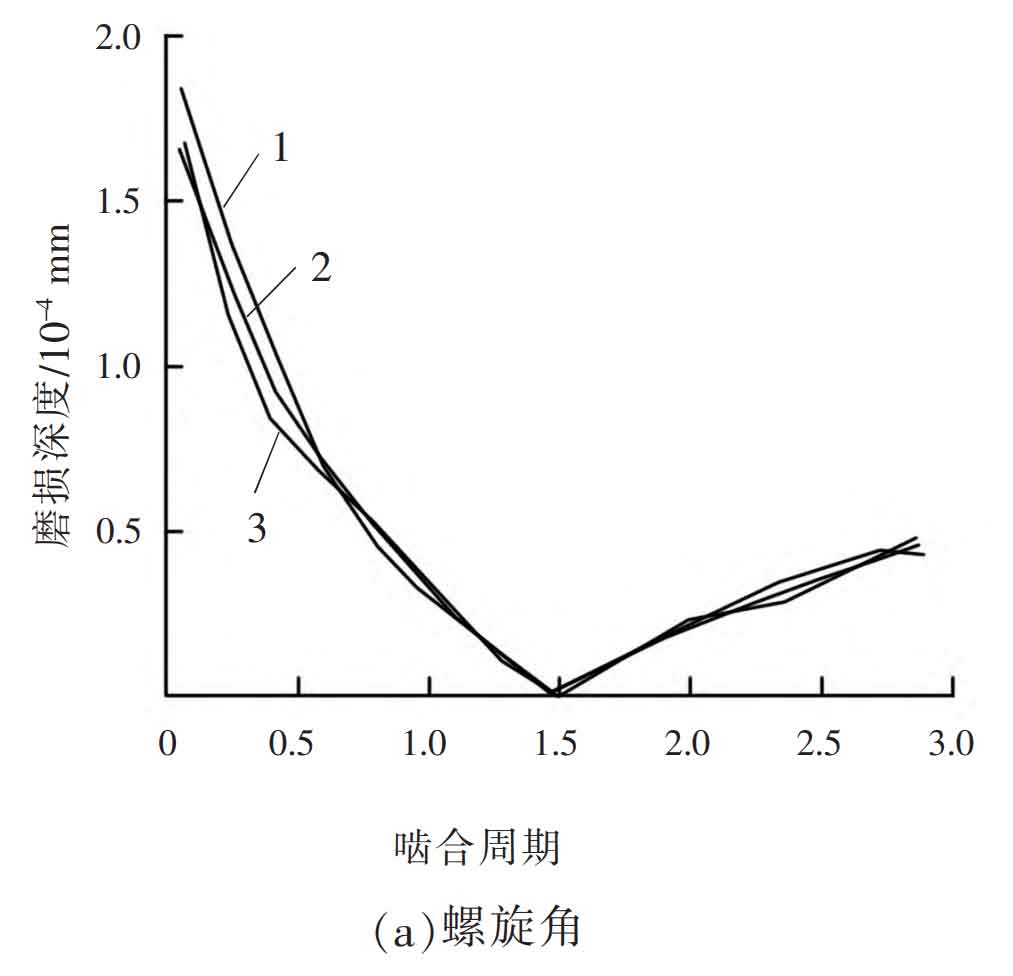

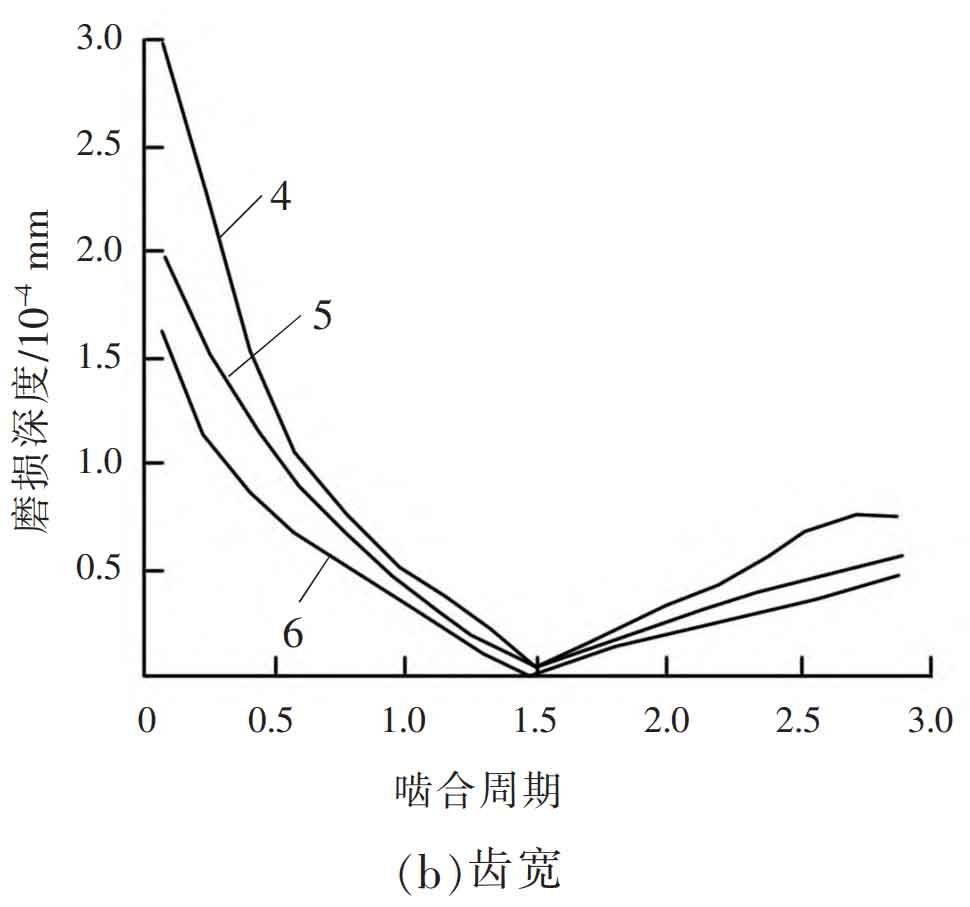

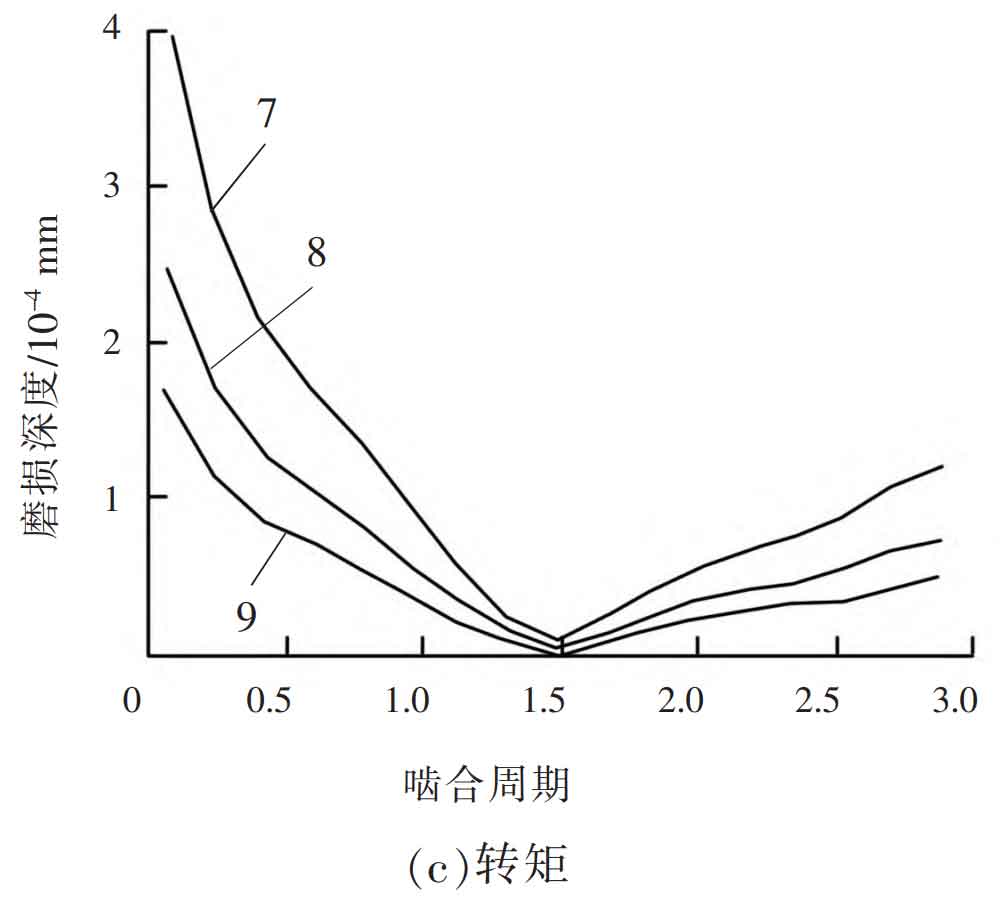

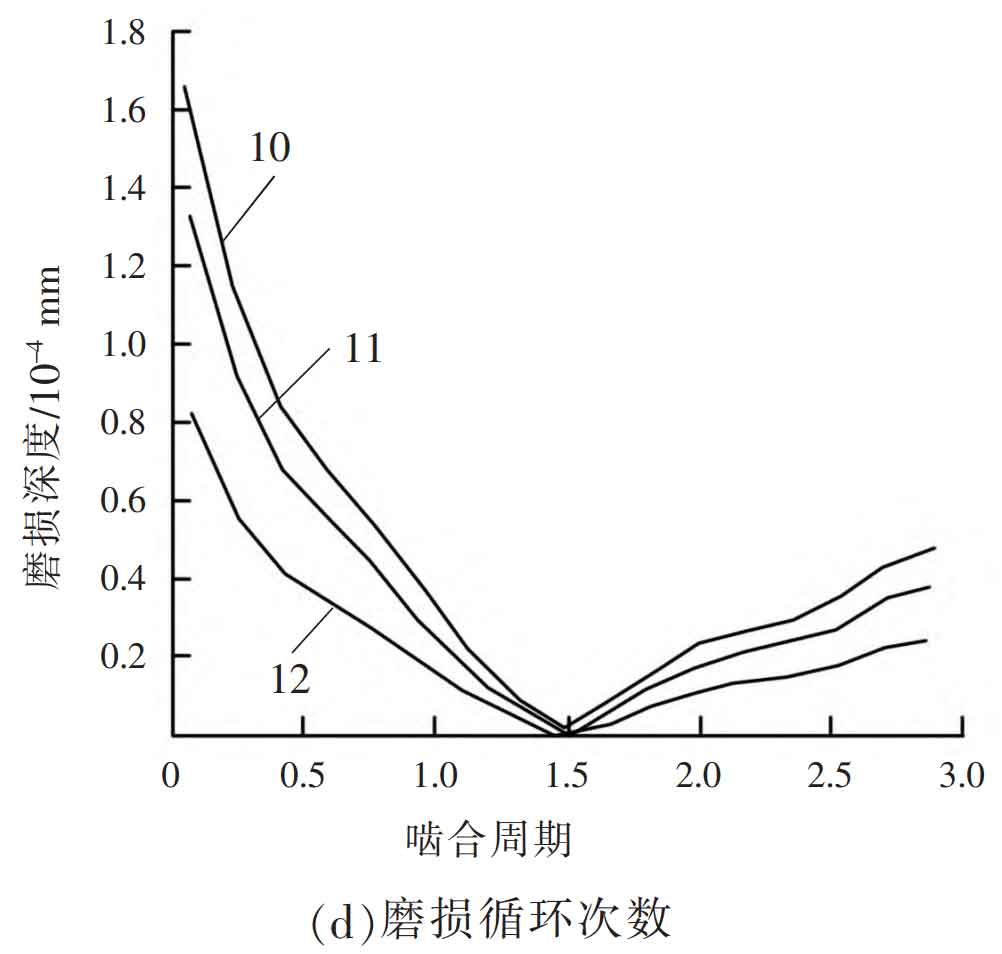

In order to further study the impact of different factors on the tooth surface wear of involute helical gear transmission systems, this paper changes the input torque, helix angle, and wear cycle times, respectively, to study the impact of the above parameter values on the cumulative wear depth of the tooth surface. As the cumulative wear depth distribution of the driving and driven gear tooth surfaces is almost consistent, and the wear depth of the driven gear tooth surface is relatively small, only the wear depth of the driving gear tooth surface is studied. The influence of different factors on the cumulative wear depth of the driving gear tooth surface is shown in the figure.

From Figure (a), it can be seen that the cumulative wear depth of the driving gear tooth surface decreases with the increase of the spiral angle, but the change is small. This is because the increase of the spiral angle of the helical gear increases the length of the contact line, resulting in a decrease in the unit line load and average contact pressure; As can be seen from Figure (b), an increase in tooth width decreases the unit line load and average contact pressure acting on the contact line, and also leads to a gradual decrease in the amount of wear on the tooth surface of the driving gear; As can be seen from Figure (c), as the input torque increases, the accumulated wear depth of the driving gear tooth surface significantly increases, because the input torque increases the unit line load and the average contact pressure. The wear amount of gear tooth surface is closely related to the number of wear cycles; As can be seen from Figure (d), the cumulative wear depth of the tooth surface gradually increases with the increase in the number of load cycles.