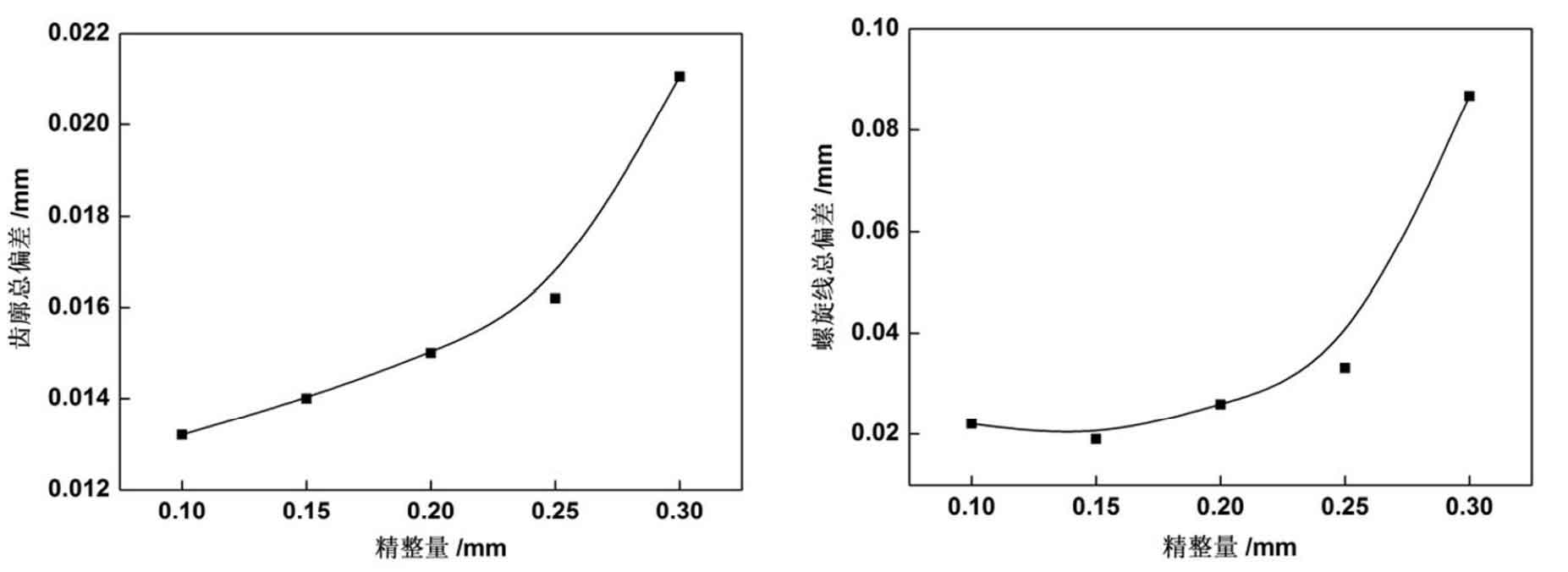

The sizing belt of shaping die is one of the important process parameters affecting the forming accuracy of spur gear. Shaping quantity is one of the important process parameters of cold shaping process, which directly affects the accuracy of straight cylindrical gear after shaping. Through the numerical simulation of the cold shaping of spur gear under different shaping quantities, the simulation results are extracted for the tooth surface reconstruction of spur gear, and the measurement results as shown in the figure are obtained.

(b) Variation diagram of total deviation of helix with shaping amount

Figure (a) shows the variation of the total deviation of the spur gear profile with the reshaping amount. It can be seen from the figure that the total deviation of the tooth profile increases with the increase of the reshaping amount. The total deviation of the tooth profile is stable at grade 7 of the tooth profile accuracy when the reshaping amount is greater than 0.25mm, and the tooth profile accuracy is grade 8. Figure (b) shows the variation of the total deviation of the helix with the shaping amount. The total deviation of the helix increases with the increase of the shaping amount. The tooth direction accuracy of the spur cylindrical gear is the highest after cold shaping in the range of 0.1 ~ 0.2mm. When a small shaping amount is used to shape the tooth, the tooth will undergo small plastic deformation or even only elastic deformation through the shaping die. When the constraint of the die disappears, the elastic recovery will occur, and the tooth surface can not be shaped effectively. Therefore, too small shaping amount can not effectively improve the accuracy of spur cylindrical gear. When too much shaping is used to shape the tooth, the deformation area becomes larger and the tooth surface has severe plastic deformation, which can not achieve the purpose of tooth shape shaping. Based on the above analysis, the bilateral shaping amount of tooth parts should be in the range of 0.1 ~ 0.2mm.