The sizing belt of shaping die is one of the important process parameters affecting the forming accuracy of spur gear. The sizing belt length of shaping die is 5mm, 10mm, 15mm, 20mm and 25mm respectively for numerical simulation. The shaping amount is 0.15mm, and the cold shaping method of only adjusting the tooth surface of spur gear is adopted.

(b) Variation of total deviation of helix with the length of sizing strip

Fig. 1 (a) shows the variation of the total deviation of the spur gear profile with the length of the sizing belt calculated by numerical simulation. It can be seen from the figure that the total deviation of the tooth profile decreases with the increase of the length of the sizing belt. After the length of the sizing belt exceeds 10mm, the total deviation of the tooth profile will be less than 0.019mm, and the tooth profile accuracy will be improved to more than Grade 7. Figure 1 (b) shows the variation of the total deviation of the helix with the length of the sizing belt calculated by numerical simulation. The total deviation of the helix decreases with the increase of the length of the sizing belt. After the length of the sizing belt exceeds 10mm, the total deviation of the helix is stable in the range of 0.018 ~ 0.02mm. At this time, the tooth direction accuracy is grade 7.

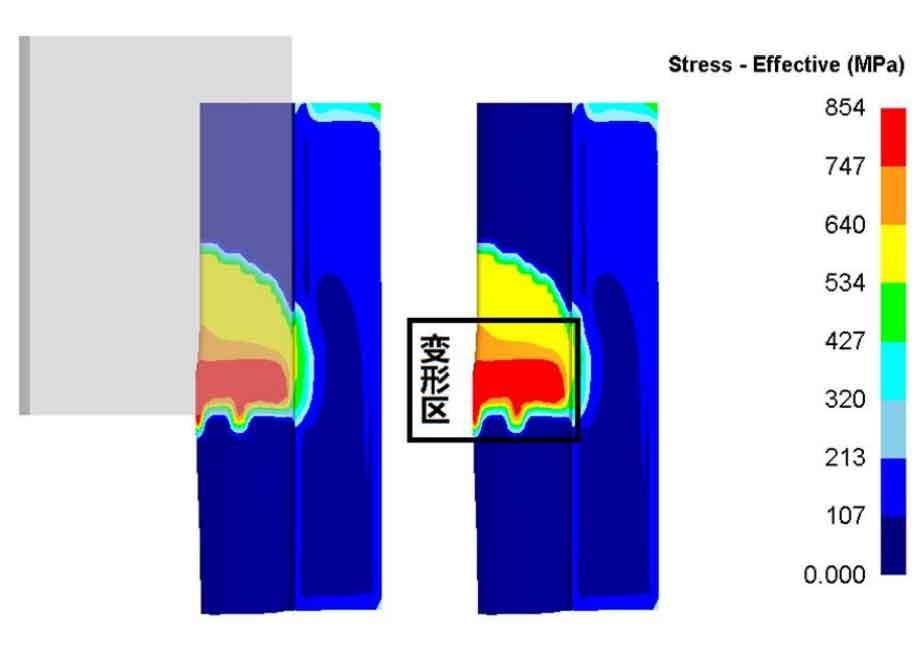

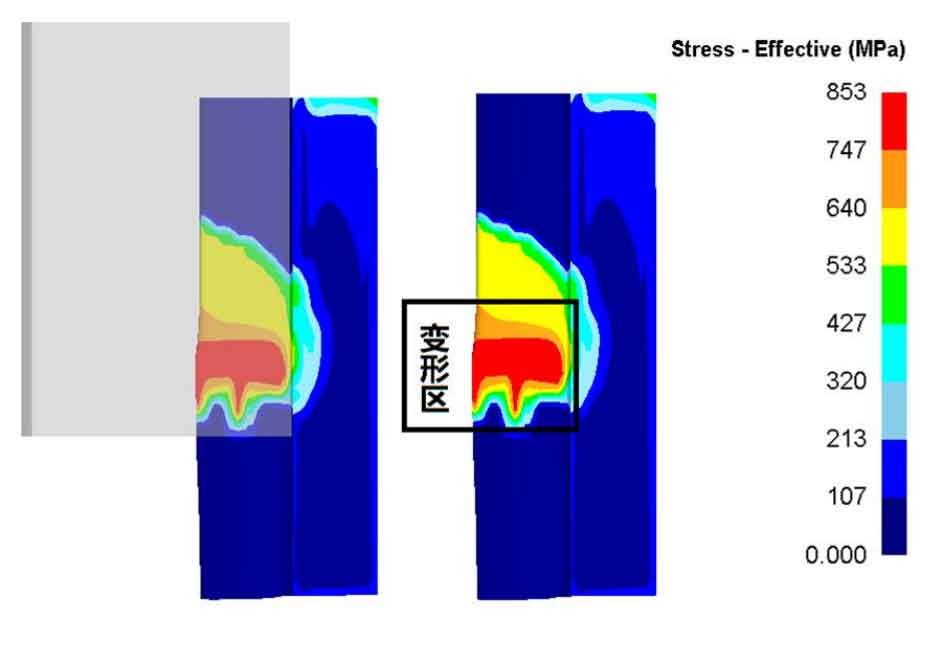

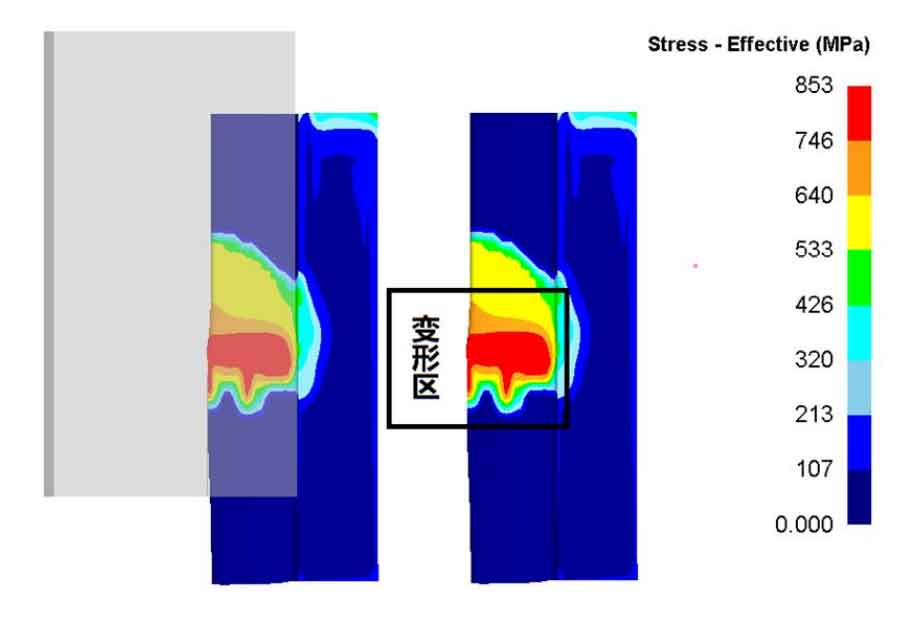

When the length of the sizing belt is 5mm, the plastic deformation area of the tooth surface of the spur cylindrical gear exceeds the length of the sizing belt. As shown in Fig. 2 (a), the tooth will still deform after passing through the die, so the gear precision after shaping is low and the purpose of shaping cannot be achieved; When the length of the sizing belt is 10mm, the tooth surface plastic deformation zone is within the length range of the sizing belt, as shown in Fig. 2 (b); When the length of the sizing belt is 25mm, the tooth surface is still in the sizing belt after plastic deformation. At this time, only rigid translation is performed, as shown in Fig. 2 (c). Based on the above analysis, the sizing belt is too short, the shaping effect is poor, the sizing belt is too long, and the tooth surface is prone to defects. When the length of the sizing belt is 10mm, the precision of the straight cylindrical gear after shaping is high and the tooth surface quality can be guaranteed. Therefore, the sizing belt length of the shaping die should be 10mm.