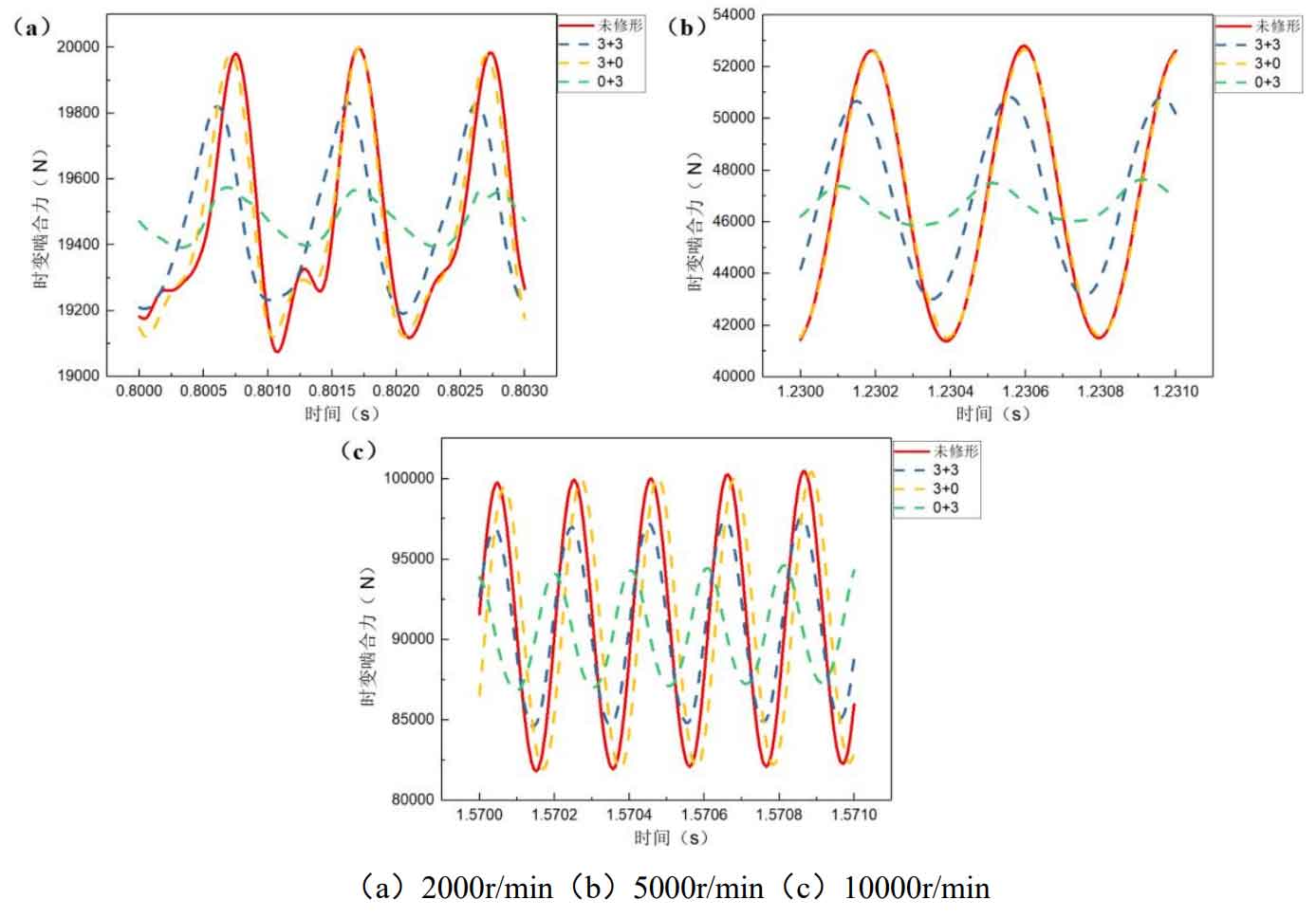

There are three schemes for drum shape optimization modification of tooth profile, namely, the modification amount of driving wheel is 3 μ m. Modification amount of driven wheel 3 μ m. Modification amount of driving wheel 3 μ m. Modification amount of driven wheel 0 μ m. Modification amount of driving wheel 0 μ m. Modification amount of driven wheel 3 μ m。 Figure 1 shows the time varying meshing force curves of the helical gear pair before and after the tooth profile drum optimization modification at different speeds. It can be seen that if the tooth profile drum modification is carried out on the driving and driven gears (small big gears) or only on the driven gears (big gears), the time varying meshing force of the helical gear pair not only decreases significantly, but also the meshing impact phenomenon disappears. However, if only the driving gear (pinion) is modified, not only the time-varying meshing force of the helical gear is not reduced, but also the meshing impact is still serious. Since the modification effect is too poor compared with the other two drum optimization schemes, this scheme is discarded.

The peak values of time-varying meshing force of the helical gear pair of the reducer of an electric vehicle after the drum shape optimization modification of the active and passive gear profiles are 19826.629N, 50804.301N and 97544.961N at low, medium and high speeds respectively, which are 172.484N, 1989.976N and 2936.359N lower than those before the modification; However, only after the crown shape optimization and modification of the passive gear profile of the helical gear pair, the peak values of the time-varying meshing force at low speed, medium speed and high speed are 19573.523N, 47619.484N and 94555.805N respectively, and the decreasing degrees are 425.59N, 5174.793N and 5925.515N respectively.

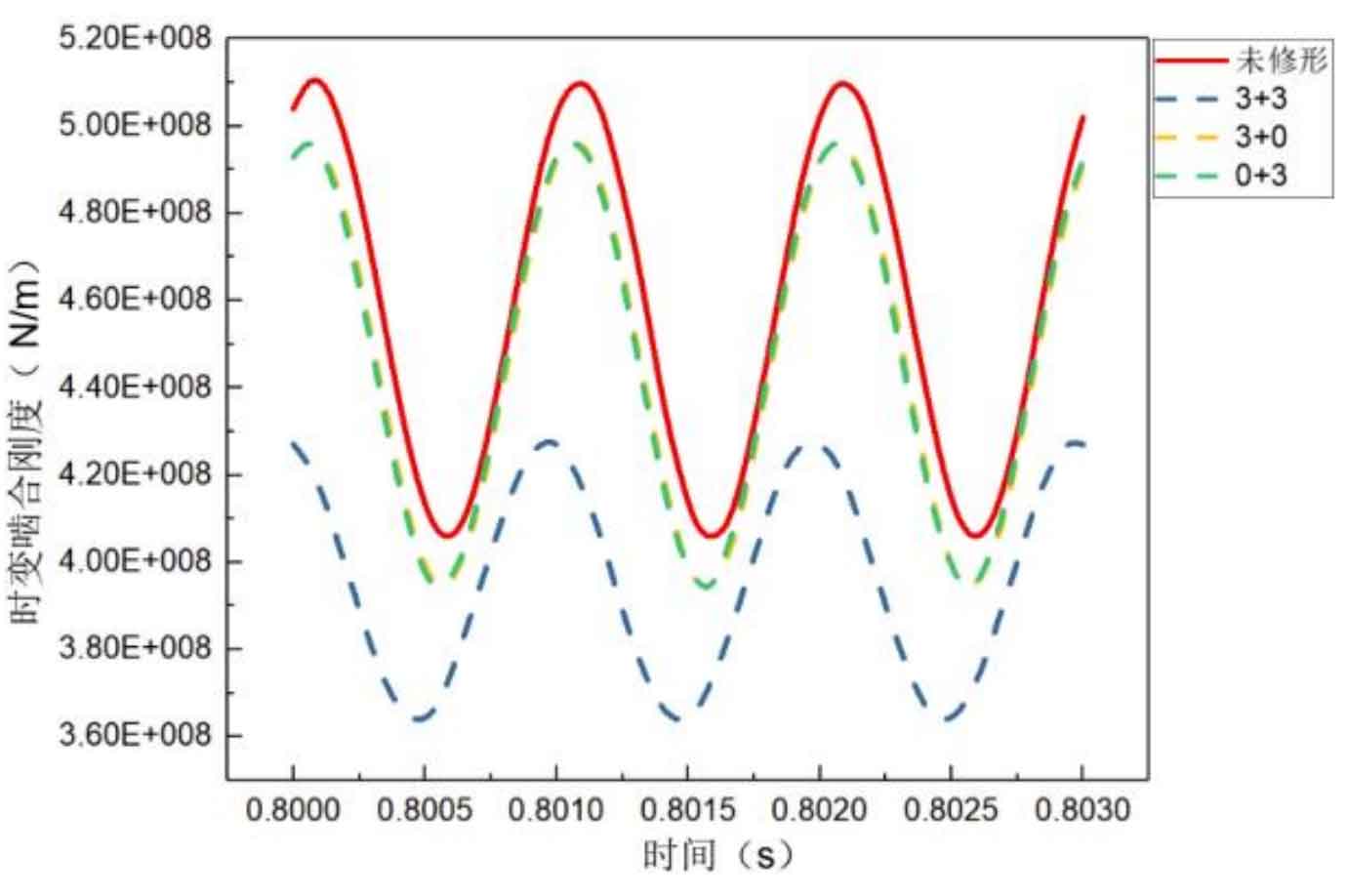

Figure 2 shows the time-varying meshing stiffness curves of the helical gear pair before and after the drum shape optimization modification of the tooth profile. It can be found that the time-varying meshing stiffness of the driving and driven gears (small big gears) is the lowest after the drum shape modification of the tooth profile at the same time, and the fluctuation range is reduced to 3.64 × 108N/m~4.27 × 108N/m, with a peak decrease of 16.3%; However, the time-varying meshing stiffness is the same regardless of the drum shape optimization modification of the driving and driven gear tooth profiles, and the peak value drops to 4.96 × 108N/m, a decrease of 2.7%.

To sum up, the selection of modified helical gear is quite critical for the drum shape modification of tooth profile. If the main purpose is to reduce the stiffness excitation of helical gear pair, it is recommended to modify the big and small gears at the same time; If the goal is to reduce the time-varying meshing force of the helical gear pair, eliminate the meshing impact and prevent the violent vibration of the helical gear pair, it is recommended to modify the large gear or large and small gears at the same time. In addition, the drum shape optimization modification of the driving gear (pinion) can also reduce the stiffness excitation to a certain extent, but the effect is obviously relatively poor, so it is not recommended.