According to the finite element simulation results of and axial displacement, the assembly offsets of 0.05 mm, 0.1 mm, 0.15 mm and 0.18 mm are taken for the gear pair respectively, and the compensation for the alignment error of herringbone gear is analyzed.

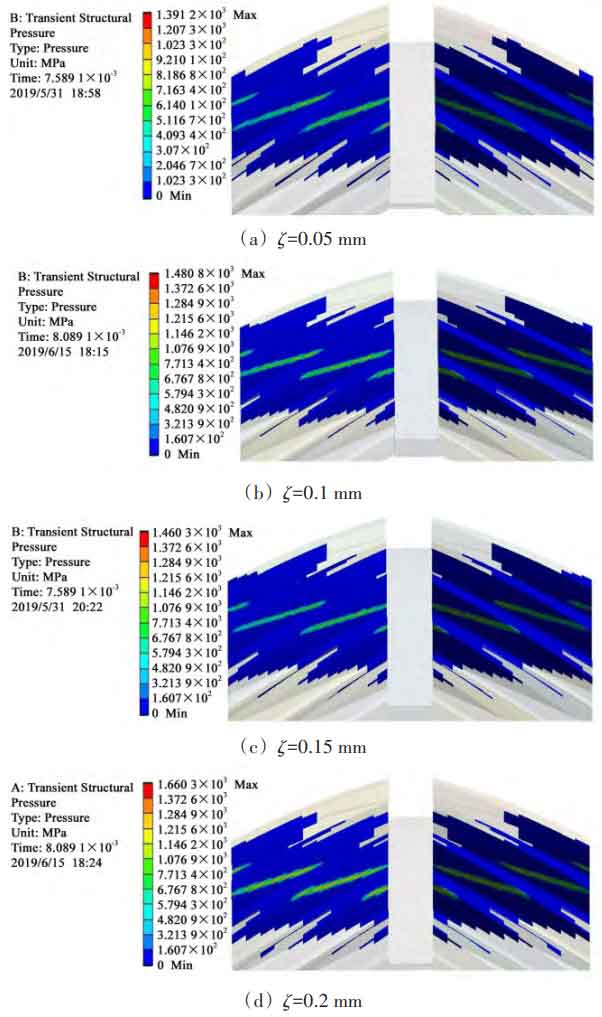

The cloud diagram of tooth surface contact stress after compensation is shown in Figure 1. As shown in Figure 1, it is found that the left and right tooth surfaces of herringbone gear have good contact stress consistency, the gear eccentric load has been significantly improved, and the larger the value of centering error, the better the compensation effect and the more stable the bearing transmission.

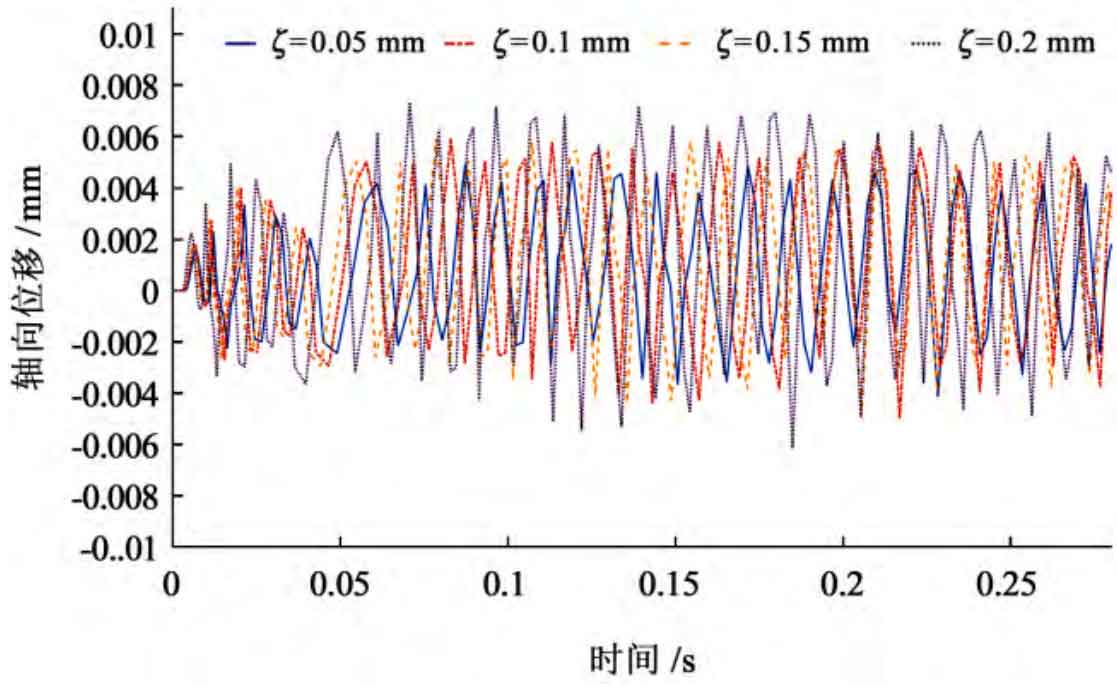

The axial displacement variation curve of the compensated herringbone gear is shown in Fig. 2. After compensation, the sudden change of axial displacement in the initial stage of gear pair is improved, and the overall fluctuation amplitude of the curve is reduced, which is 0 μ M, and the maximum values are 4.93 respectively μ m、5. 85 μ m、5. 92 μ M and 7.83 μ m. The periodic variation law is more stable, which reduces the axial vibration of the system.

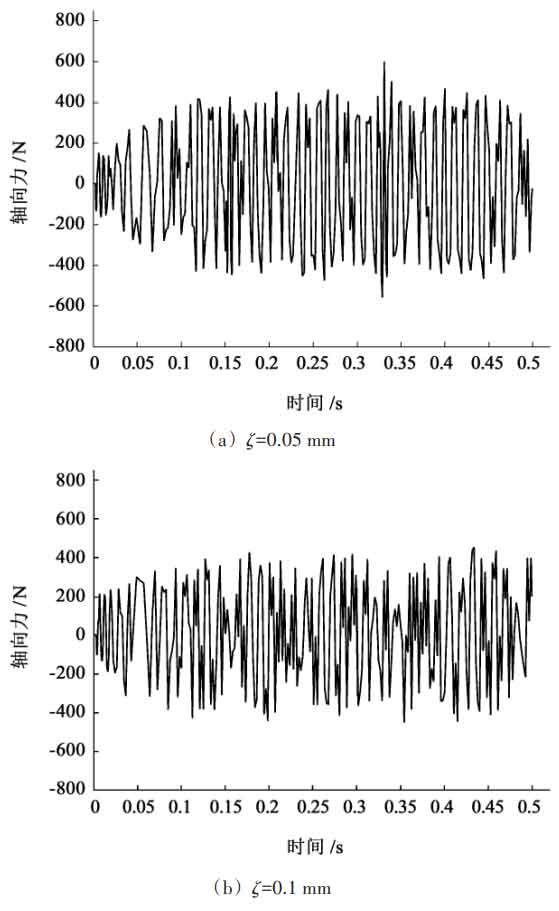

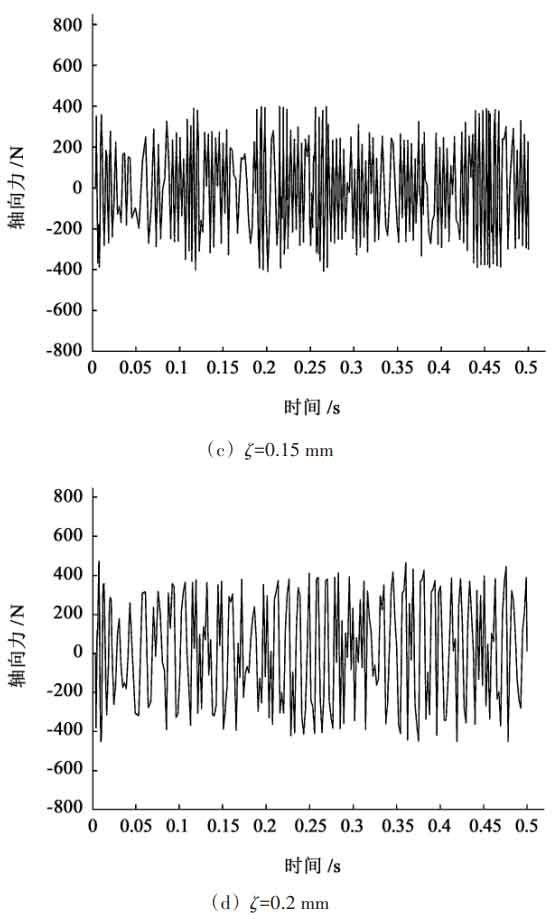

The axial force variation curve of the compensated herringbone gear is shown in Figure 3. Similar to the change of axial displacement after compensation, the overall axial force after compensation tends to be stable without violent fluctuation. The axial force of herringbone gear system with different centering errors is narrowed and fluctuates periodically in the range of 600 n. In the loading stage, there is no sudden change of force caused by violent collision. The average axial forces are 56.14 n, 55.37 n, 62.98 N and 64.68 n respectively, accounting for 1.48%, 1.31%, 1.78% and 1.82% of the unilateral axial peak force respectively, indicating that the axial force of the compensated gear pair in meshing transmission has been basically offset, the transmission stability has been improved and the axial vibration has been effectively reduced. Therefore, it is of great practical significance to compensate the centering error of herringbone gear.