The numerical calculation of the fretting friction instability state of the gear shoulder during the operation of the gear shaft is carried out by using the data, and the relationship between the preloading torque TP, the interference value Δ, the transmission power Pt and the friction factor μ on the damping ratio η of the fretting friction instability of the gear shoulder is studied and analyzed. The results are shown in figure 1-figure 4 respectively.

(1) Influence of preloading moment on fretting friction instability of gear shaft shoulder

When the interference is 0.045mm, the transmission power is 550KW, and the friction coefficient μ = 0.11, the relationship between the pre tightening torque TP and the damping ratio η of fretting friction instability under different loads is shown in the figure:

It can be seen from the figure that when the transmission power of the gear shaft is fixed, the damping ratio of fretting friction instability increases linearly with the increase of preloading moment. When the pre tightening torque is constant, the damping ratio of fretting friction instability increases with the increase of tightening torque. The main reason is that the force on the shoulder of the gear increases with the increase of the pre tightening torque, and the force on the shoulder of the gear increases correspondingly when other conditions are not changed. It can be seen that the larger the preloading torque of the gear shaft, the more obvious the friction instability of the gear shaft shoulder and the more serious the fretting wear.

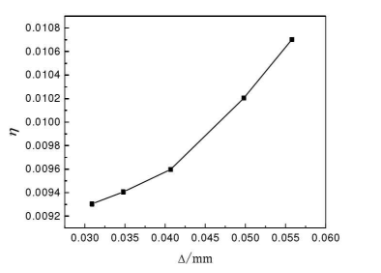

(2) Influence of interference on fretting friction instability of gear shaft shoulder

According to the formula for calculating the interference of mechanical parts, the range of the interference between the gear shaft and the bearing is 0.031mm-0.056mm. When the pre tightening torque is 480n · m and the transmission power is 550KW, the relationship between the interference and the fretting friction damping ratio is analyzed, as shown in the figure. When the amount of interference changes, the force generated by the interference fit between the gear shaft and the bearing and the preload generated by the preload torque are transmitted to the shaft shoulder, and the force will change accordingly, which will affect the magnitude of the fretting friction damping ratio of the shaft shoulder. Therefore, under a certain preload moment, the interference has a great influence on the fretting friction damping ratio of the shoulder.

It can be seen from the figure that when the interference is constant, the damping ratio of fretting friction instability increases approximately linearly with the increase of preload moment. When the preload moment is constant, the damping ratio increases with the increase of interference. The main reason is that when other conditions are not changed, the force on the gear shoulder increases with the increase of the interference, which leads to the increase of the damping ratio of the fretting friction instability of the gear shoulder.

(3) Influence of transmission power on fretting friction instability of gear shaft shoulder

Transmission power is one of the important external loads on the gear transmission mechanism. When studying the influence of transmission power on the fretting wear of the shaft shoulder, the paper mainly analyzes the influence on the relative displacement amplitude and normal load of the contact surface between the shaft shoulder and the bearing inner ring. Combined with the actual working condition of the gear transmission mechanism, five kinds of transmission power are selected to influence the force on the shaft shoulder. The change rule of the fretting friction damping ratio of the gear shoulder with the transfer power is shown in Fig. 3.6: when other parameters are kept constant, the fretting friction damping ratio of the gear shoulder increases linearly with the increase of the transfer power. The main reason is that the force of the gear shoulder increases with the increase of the transmission power. When other conditions are not changed, the force of the gear shoulder increases correspondingly, the greater the degree of fretting friction instability of the gear shoulder is. It can be seen that the greater the transmission power of the gear shaft is, the more obvious the friction instability of the gear shaft shoulder is, and the more serious the fretting wear is. Therefore, the long-term operation of the gear shaft under high load should be avoided as far as possible.

(4) Influence of friction factor on fretting friction instability of gear shaft shoulder

When the pre tightening torque of the bolt is 480n · m and the transmission power is 500kW, the relationship between the damping ratio of the fretting friction instability of the gear shoulder and the friction coefficient between the gear shaft and the bearing is shown in the figure:

It can be seen from the figure that the damping ratio of fretting friction instability increases with the friction coefficient between the gear shaft and the bearing when the preloading moment is fixed. For the preloading torque TP = 480n · m, when the static friction coefficient μ = 0.18, the damping ratio η gt; 0.005 of the fretting friction instability of the gear shaft shoulder end surface begins to occur; for the preloading torque TP = 780N · m, when the static friction coefficient μ = 0.11, the fretting friction instability of the gear shaft shoulder begins to occur. Therefore, on the premise of ensuring that the preloading torque can meet the normal operation of the gear shaft, in order to effectively avoid the phenomenon of fretting wear instability of the gear shaft shoulder, it is necessary to maintain the static friction coefficient within a proper range by a better method.