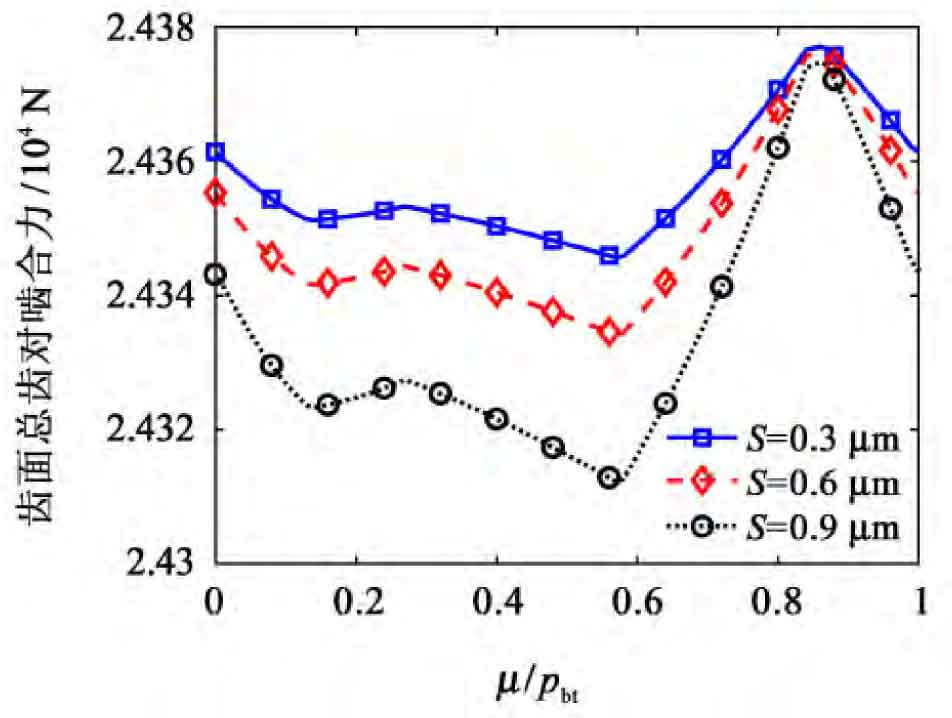

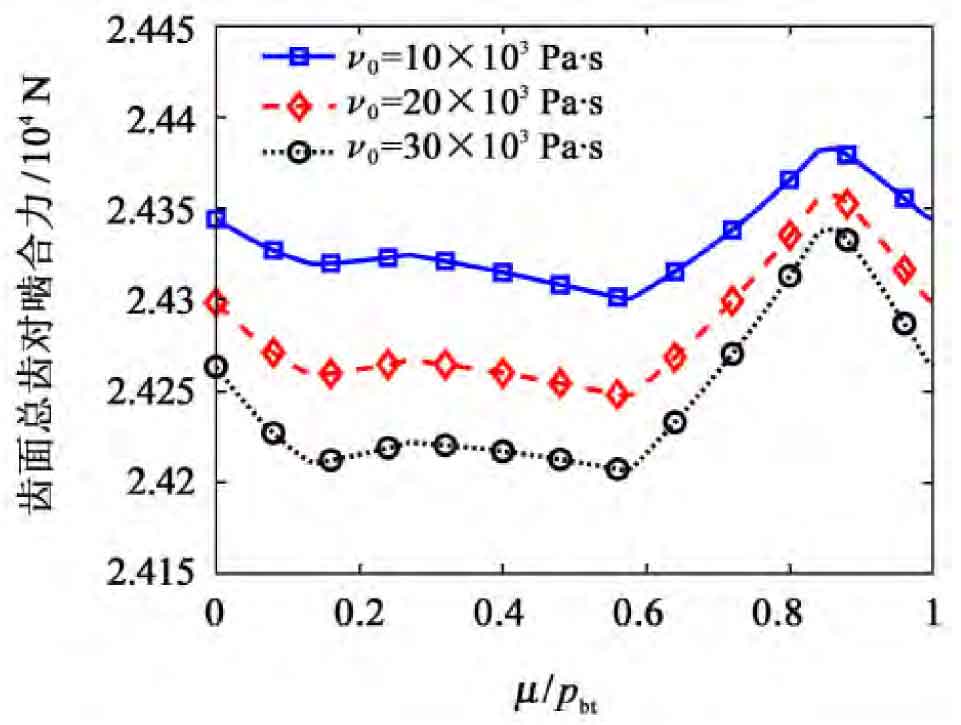

Tooth surface roughness and lubricating oil viscosity are the main factors that affect the friction coefficient of tooth surface. Through the effect of friction, the meshing force of tooth surface will change. Figure 1 shows the influence of working parameters on the meshing force of tooth surface.

It can be seen from Fig. 1 that the meshing force of tooth surface decreases with the increase of tooth surface roughness and dynamic viscosity of lubricating oil, and the influence is more significant in the multi tooth meshing area.

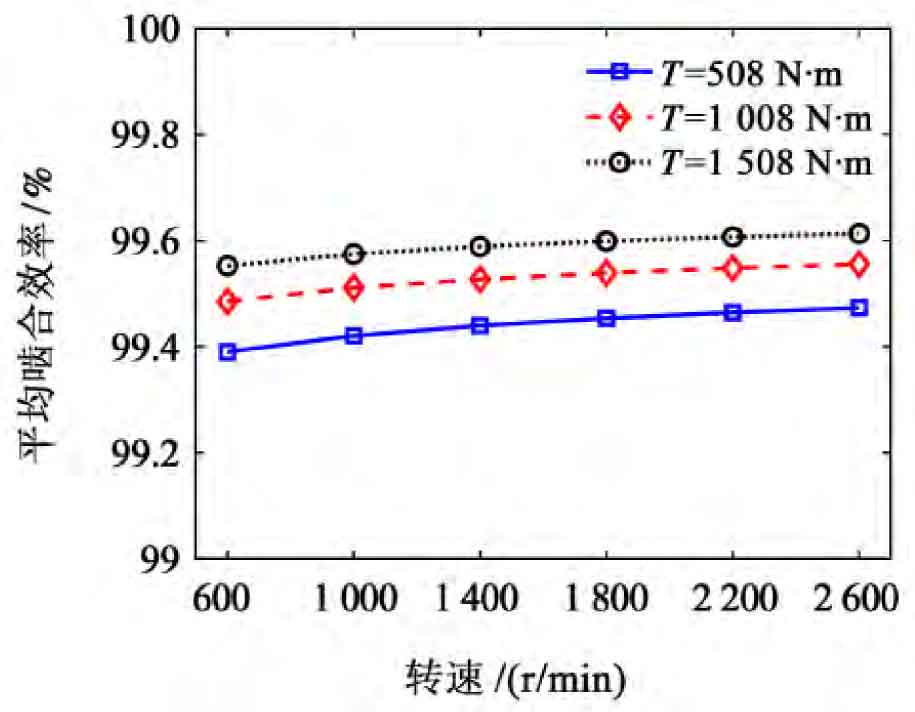

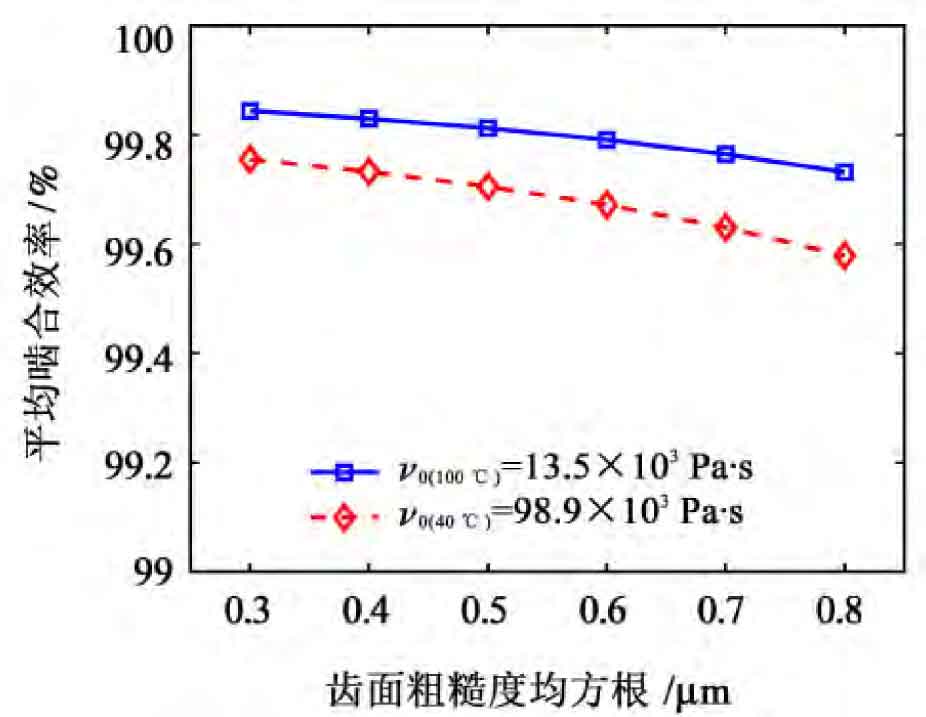

Figure 2 shows the influence of working parameters on the average meshing efficiency.

It can be seen from Figure 2 (a) that the gear meshing efficiency increases slightly with the increase of the speed; With the increase of torque, the meshing efficiency increases; This is consistent with the change rule of the results. It can be seen from Fig. 2 (b) that the meshing efficiency decreases with the increase of root mean square roughness of the tooth surface, and the effect is more significant when the dynamic viscosity of the lubricating oil is large at low temperature, which is also consistent with the result rule.