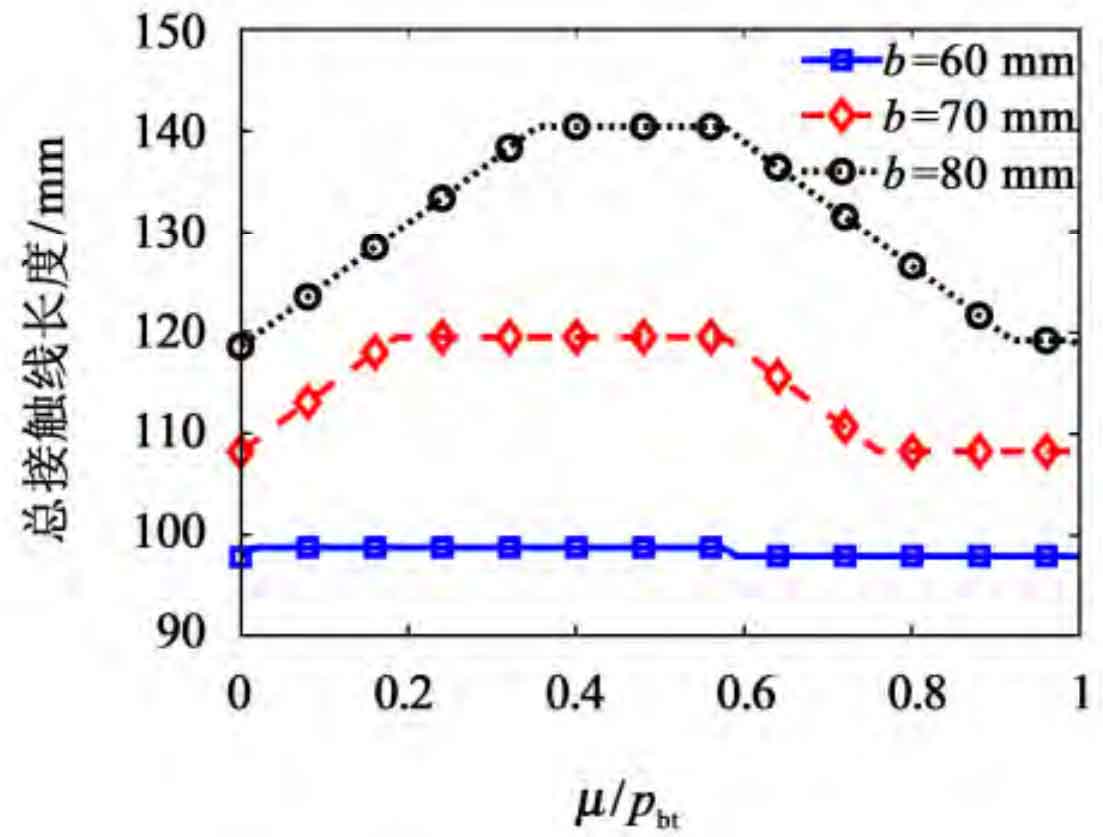

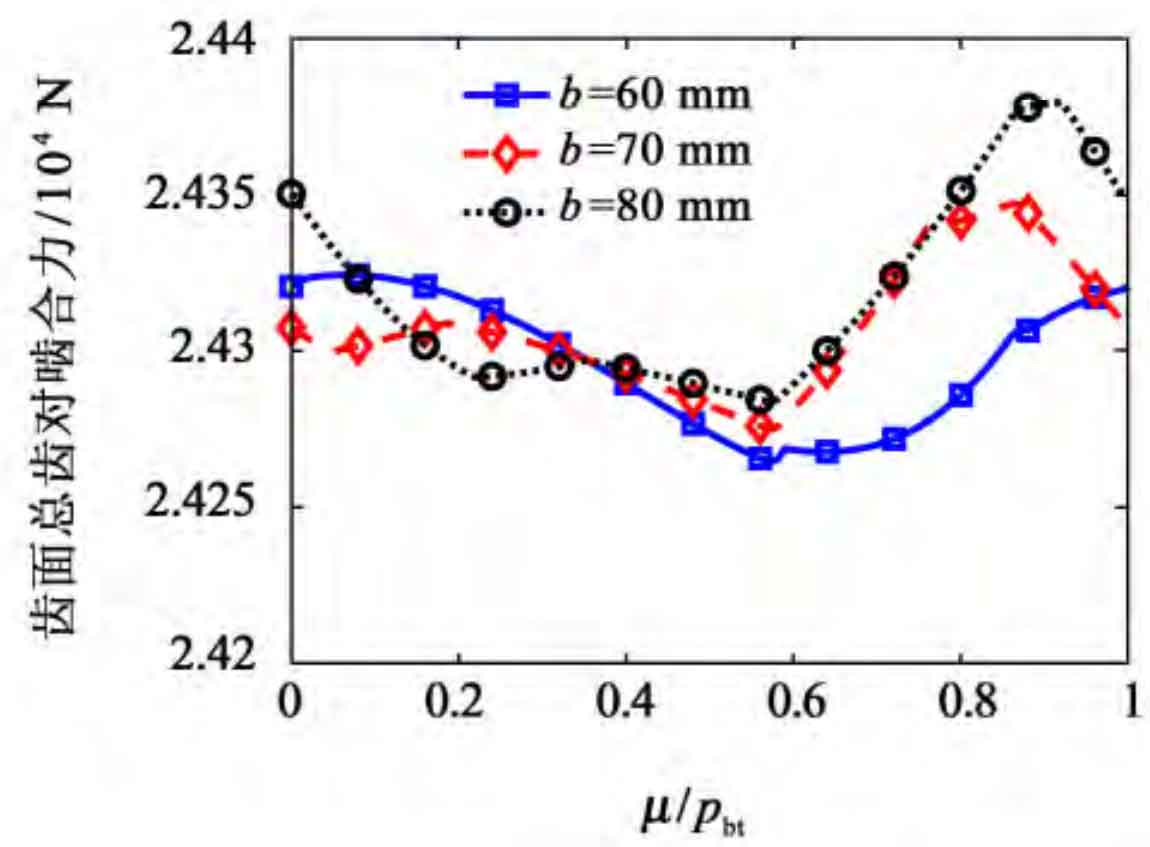

Tooth width and helix angle are the main parameters that affect the time-varying contact line of helical gears. Figure 1 shows the influence of tooth width on the meshing force of contact line and tooth surface. It can be seen from Figure 1 (a) that with the increase of tooth width, the length of helical gear contact line increases, and the fluctuation changes increase; When b=60 mm, the axial coincidence of helical gear is close to 1, the contact line is approximately a straight line, and the fluctuation is minimum. It can be seen from Fig. 1 (b) that the fluctuation of the meshing force on the tooth surface increases with the increase of the tooth width, and the fluctuation is minimum when b=60 mm.

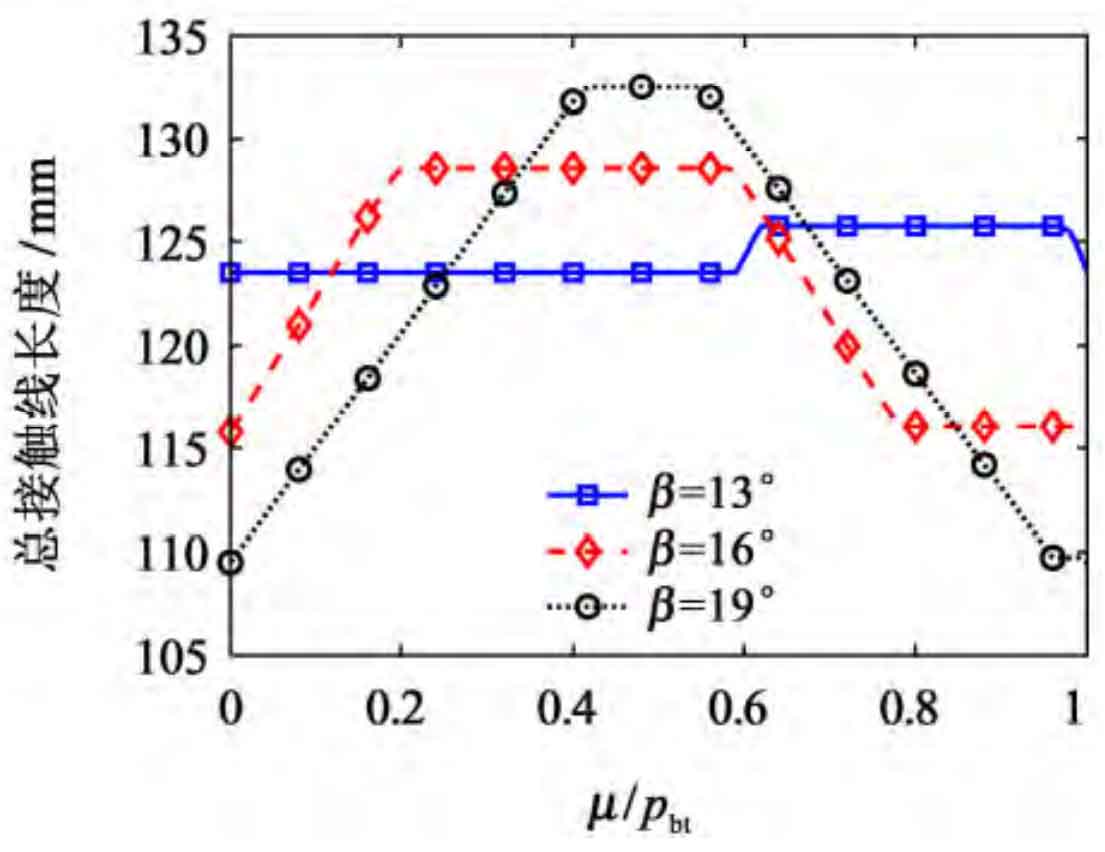

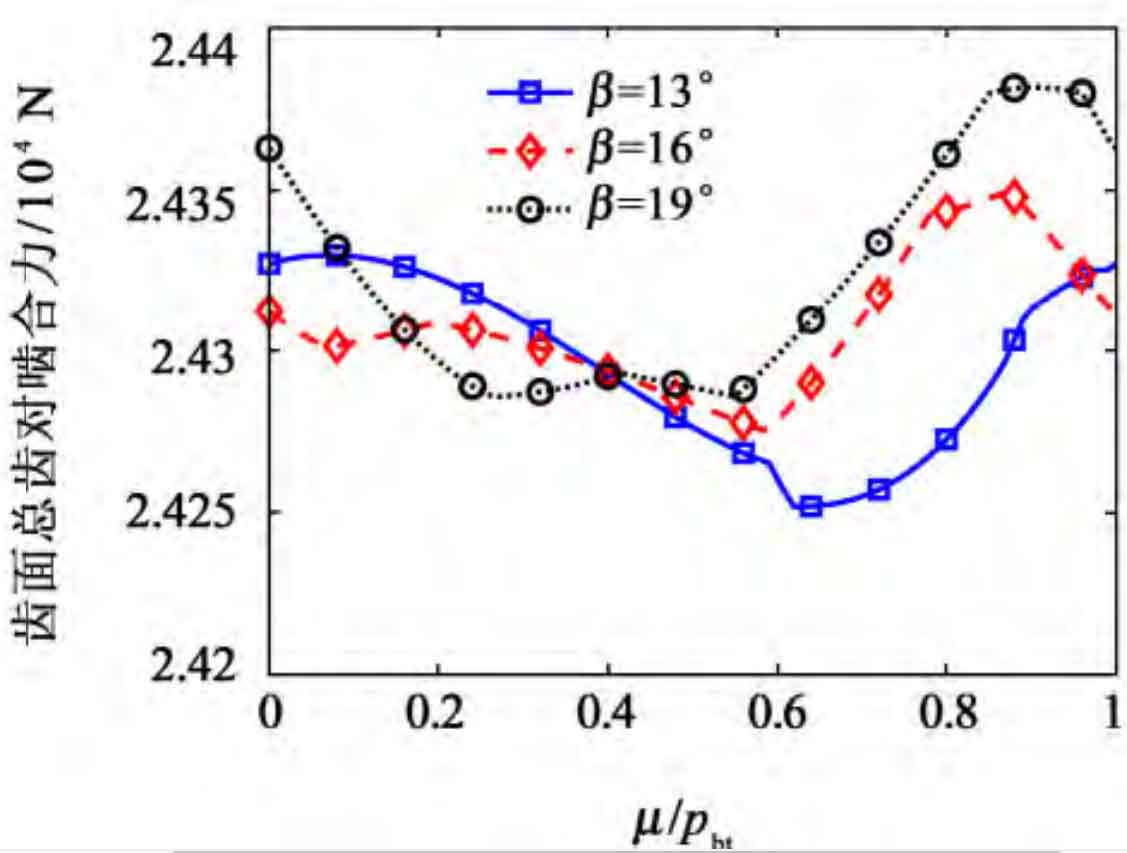

Figure 2 shows the influence of helix angle on the meshing force of contact line and tooth surface. It can be seen that when the helix angle is 13 °, the fluctuation of contact line is minimum, and the fluctuation of meshing force is also small; With the increase of helix angle, the meshing force fluctuation of contact line and tooth surface increases.

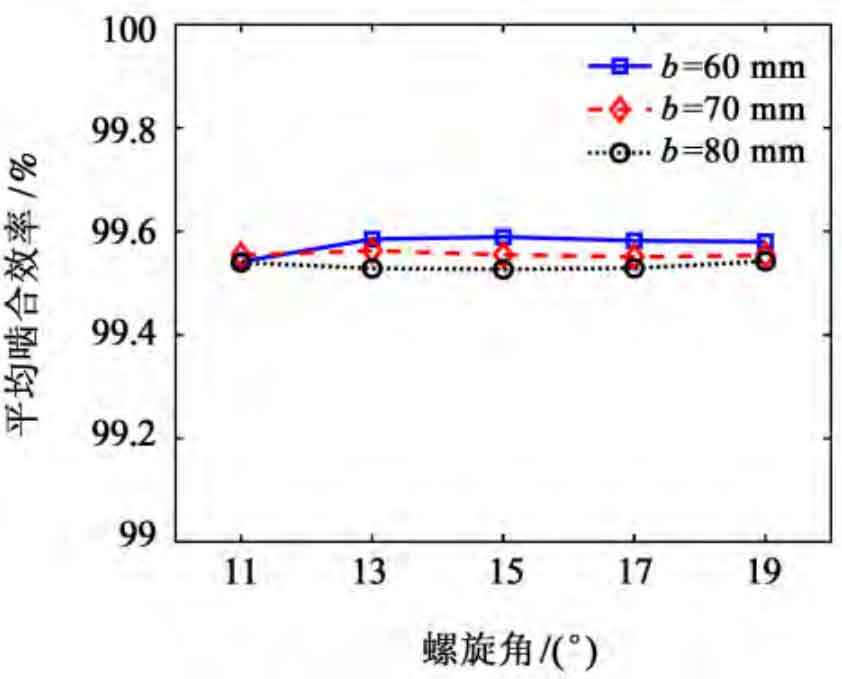

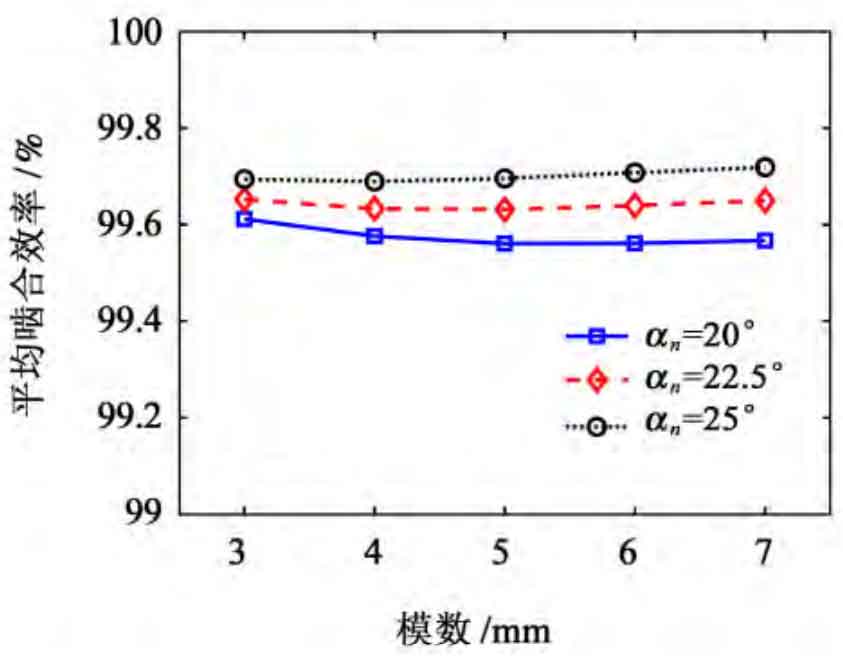

Figure 3 shows the influence of geometric parameters on meshing efficiency. It can be seen from Fig. 3 (a) that the meshing efficiency fluctuates slightly with the increase of helix angle; When the tooth width increases, the meshing efficiency decreases slightly. It can be seen from Fig. 3 (b) that the meshing efficiency increases slightly with the increase of modulus; The meshing efficiency increases with the increase of pressure angle.