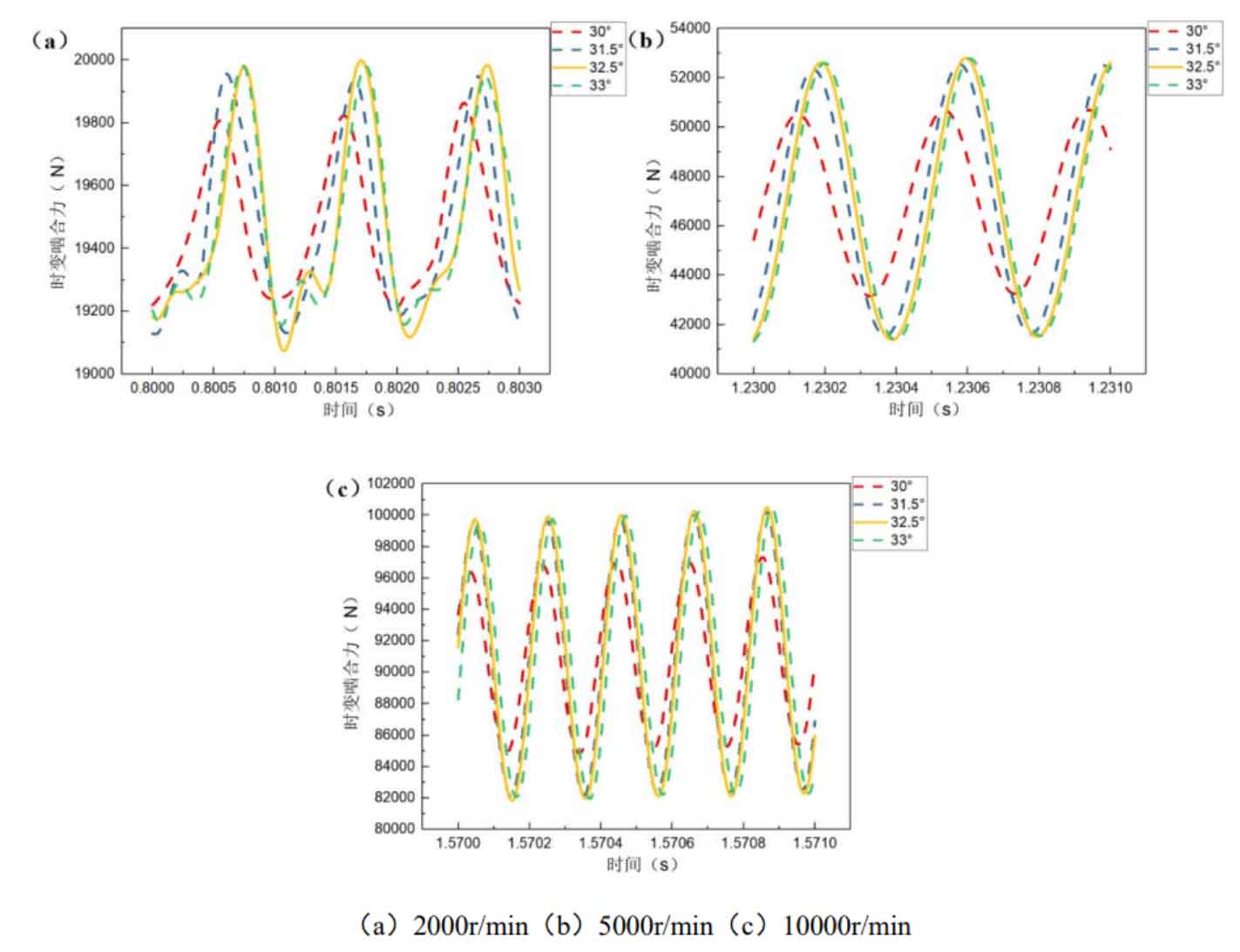

Figure 1 shows the influence curve of the helix angle on the time-varying meshing force of the helical gear pair at different speeds. When the helix angle changes from 30 ° to 32.5 °, the time-varying meshing force of the helical gear under low speed (2000r/min), medium speed (5000r/min) and high speed (10000r/min) conditions increases with the increase of the helix angle, but excessive helix angle (more than 32.5 °) will not further increase the force excitation. From Figure 1 (a), it can be found that changing the size of the spiral angle can not completely eliminate the impact of meshing in and out, but an appropriate spiral angle (30 °) can make the meshing more smooth (the curve is relatively smooth), and the time-varying meshing force is significantly reduced, thus reducing the impact of meshing in and out.

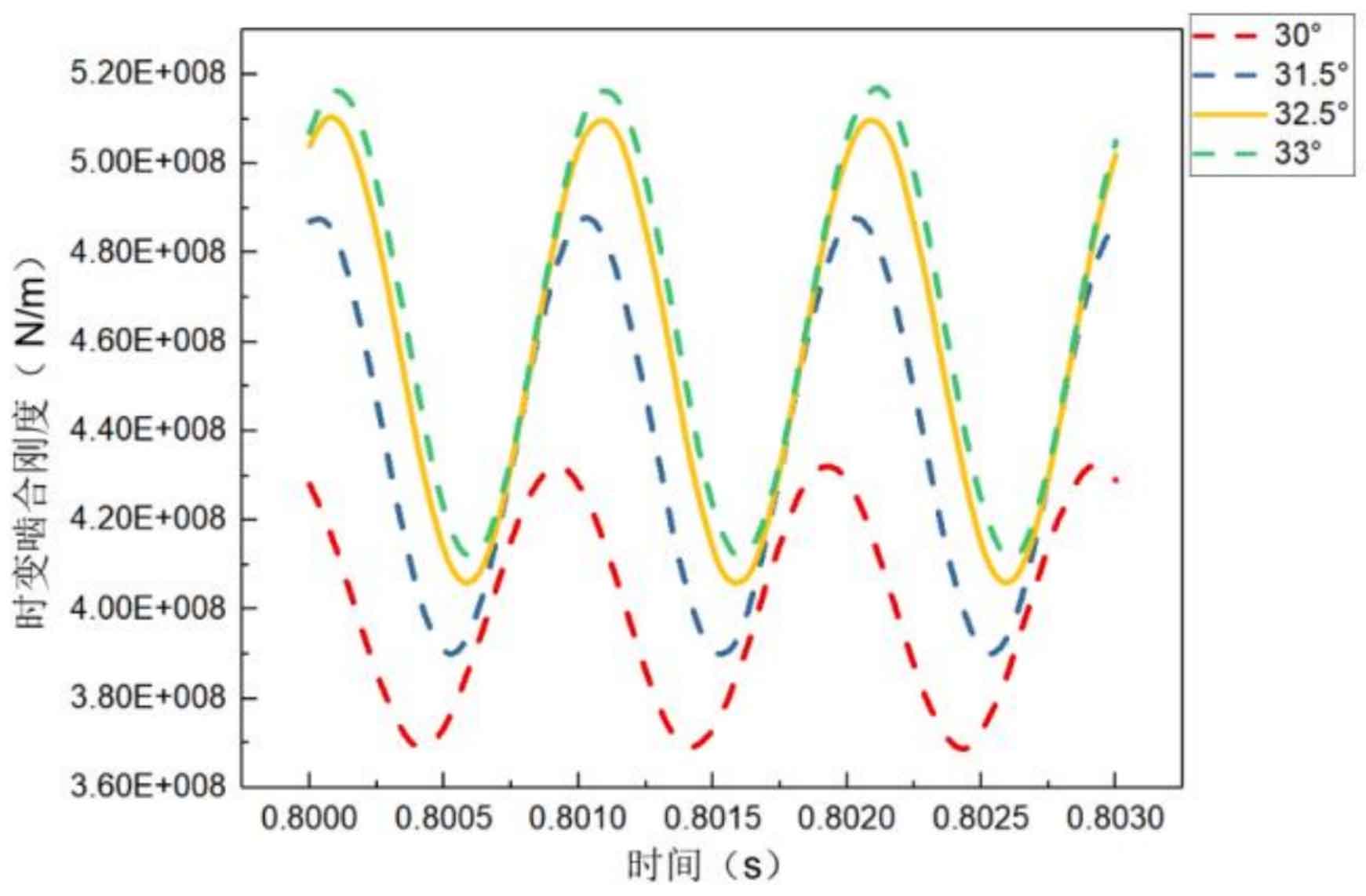

Figure 2 shows the influence curve of the helix angle on the time-varying meshing stiffness of the helical gear pair. Obviously, the larger the helix angle, the greater the time-varying meshing stiffness, and the more severe the vibration of the gear pair.

Therefore, considering that both meshing impact excitation and stiffness excitation are important factors that affect the transmission noise of helical gear pair, from the perspective of reducing dynamic excitation, small helix angle should be selected on the premise of meeting the use requirements and small time-varying meshing force.