There are many factors affecting spiral bevel gear transmission, such as error, meshing stiffness, backlash, etc., but only the error can be adjusted by robust optimization design. In the process of machining and installation of spiral bevel gears, error is a factor that cannot be ignored. Therefore, the error excitation is always real. The machining and installation errors make the real tooth profile fail to reach the expected meshing position, resulting in the change of the meshing shape of the spiral bevel gear, resulting in a large change in the instantaneous transmission ratio of the spiral bevel gear, causing the vibration of the spiral bevel gear.

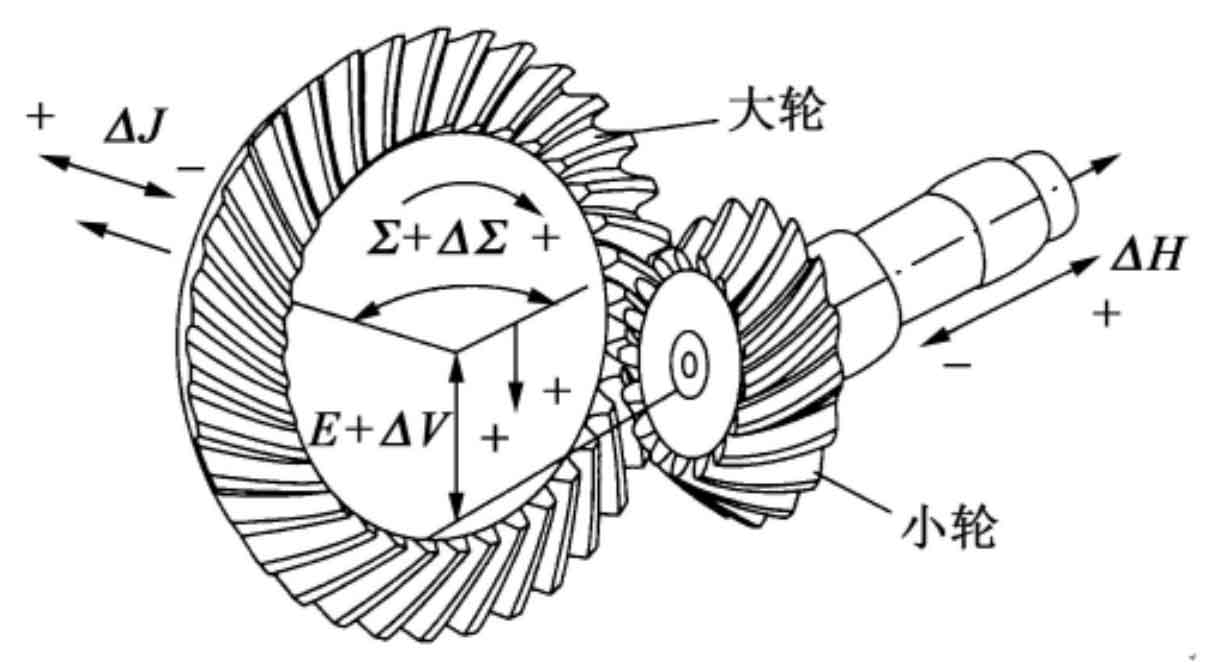

Ignore other errors and only consider the impact of installation errors. The installation error can be divided into the axial error, vertical installation error and shaft intersection error of the big and small wheels, as shown in Figure 1.

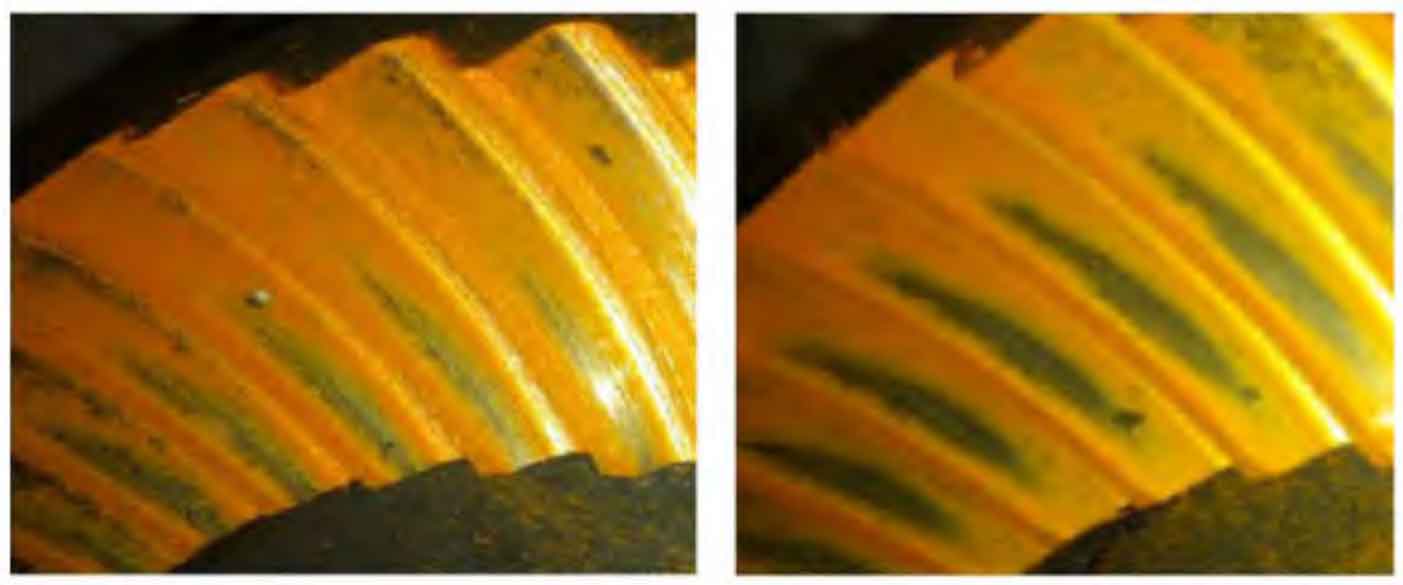

Through computer simulation, Su Hui and others analyzed the change of tooth surface contact marks under different installation errors, and studied the influence of different installation errors on the meshing performance of spiral bevel gears, as shown in Figure 2.

Wang Xiaochun et al. used the analytical method to derive the sensitivity matrix of the tooth surface of the spatial point meshing to the installation error, which provided a theoretical basis for analyzing the sensitivity of the spiral bevel gear to the installation error. Tang Jinyuan and others analyzed the influence of installation error on the tooth surface meshing of spiral bevel gears by reasonably determining the position of the initial calculation point. In order to quickly find the initial point and study the influence of installation error on the meshing characteristics of spiral bevel gears, Lu Fengxia and others proposed a new calculation method to determine the position of the initial point. Under the condition of determining the initial point, Su Yulong and others studied the influence of tooth surface contact marks on the premise of installation error.

The meshing performance of spiral bevel gears with installation errors is preliminarily studied. Because of the uncertainty of installation error, how to make spiral bevel gears insensitive to installation error in the transmission process has been paid attention by many scholars.