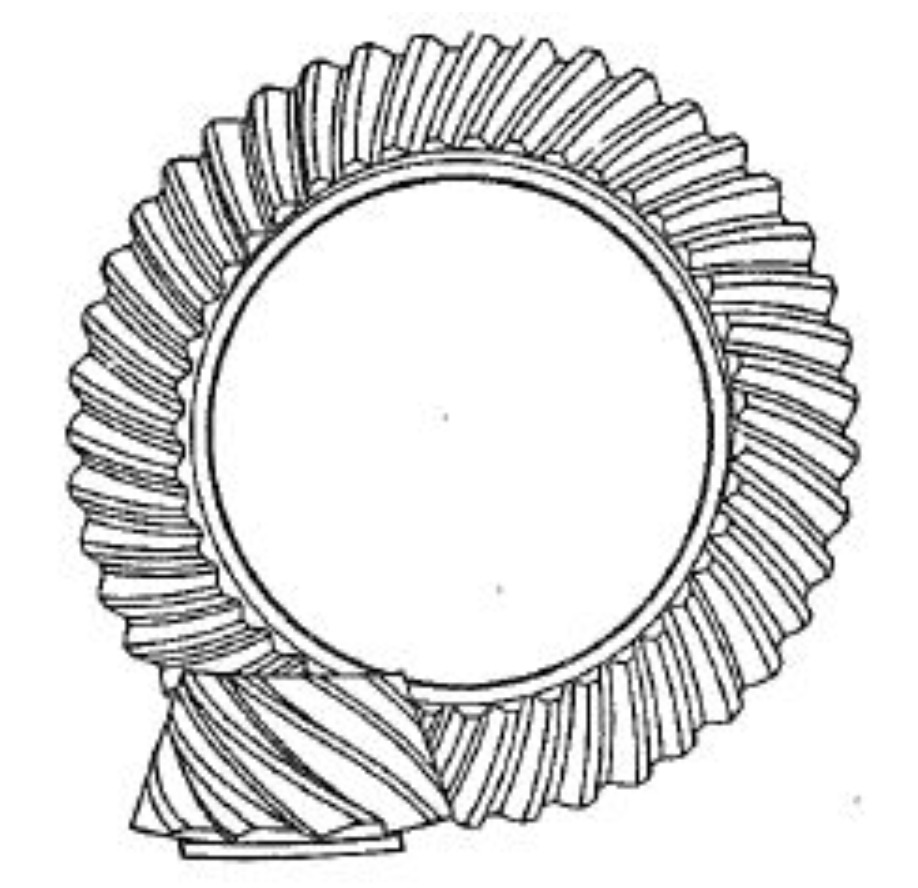

In this research, I explore the impact of machine tool adjustment parameters on the meshing performance of hypoid gears, which are critical components in automotive and aerospace industries due to their ability to transmit motion between non-intersecting shafts with high load capacity and smooth operation. The complexity of hypoid gear manufacturing arises from the numerous adjustable parameters during processing, making it challenging to control meshing characteristics such as contact patterns and transmission errors. These characteristics directly influence noise levels and service life, underscoring the importance of understanding the relationship between machine settings and gear performance. By developing mathematical models based on gear machining principles and spatial kinematics of five-axis machine tools, I aim to provide insights that can enhance the design and adjustment of hypoid gears for improved reliability.

Hypoid gears are widely used in power transmission systems because of their superior performance under heavy loads and misalignment conditions. However, achieving optimal meshing requires precise control over the manufacturing process, where even minor deviations in machine parameters can lead to significant changes in tooth contact behavior. In this study, I focus on the dual spiral method for machining hypoid gears, establishing a comprehensive framework to analyze how variations in key adjustment parameters affect the gear tooth surfaces. Through tooth contact analysis (TCA) and gear meshing theory, I derive equations that describe contact trajectories and transmission errors, enabling a detailed investigation into parameter sensitivities. This approach not only aids in troubleshooting manufacturing issues but also supports the development of robust gear designs that can tolerate operational variations.

To model the tooth surface of hypoid gears, I begin with the coordinate systems involved in the machining process. For the pinion, which is typically cut using the dual spiral method, multiple coordinate frames are defined: $S_{m1}$, $S_c$, and $S_d$ are fixed to the machine, while $S_p$ is attached to the cutter and rotates about the $z_p$ axis. The pinion undergoes a rotational motion around $x_d$ and a helical motion along $Z_{m1}$, with the tooth surface generated as the envelope of the cutter surface family. The machine adjustment parameters include angular blade position $q_1$, radial blade position $S_{r1}$, blade inclination angle $i$, blade rotation angle $j$, vertical wheel position $e_1$, machine bed position $x_b$, machine root angle $\gamma_{m1}$, axial wheel position $x_{g1}$, and helical motion coefficient $H_l$. These parameters define the relative positions and motions during cutting.

The vector function for the cutting cone formed by the straight blade in the $S_p$ coordinate system is given by:

$$r_p = \begin{bmatrix}

(r_{g1} + u_1 \sin \alpha_1) \cos \beta_1 \\

(r_{g1} + u_1 \sin \alpha_1) \sin \beta_1 \\

– u_1 \cos \alpha_1

\end{bmatrix}$$

and the unit normal vector is:

$$n_p = \begin{bmatrix}

\cos \alpha_1 \cos \beta_1 \\

\cos \alpha_1 \sin \beta_1 \\

\sin \alpha_1

\end{bmatrix}$$

Transforming these to the pinion coordinate system $S_1$ using transformation matrices, the pinion tooth surface equation and its unit normal vector become:

$$r_1(u_1, \beta_1, \phi) = M_{1p} r_p(u_1, \beta_1)$$

$$n_1(u_1, \beta_1, \phi) = L_{1p} n_p(u_1, \beta_1)$$

$$f_1(u_1, \beta_1, \phi) = n_1 \cdot \frac{\partial r_1(1:3)}{\partial \phi} = 0$$

where $f_1$ is the meshing equation for generating the pinion, $M_{1p}$ is the transformation matrix from $S_p$ to $S_1$, and $L_{1p}$ is its 3×3 rotational submatrix. For practical applications, I consider deviations in machine parameters, expressed as $X’ = X + \Delta X$, where $X$ represents the nominal parameters and $\Delta X$ the errors. Incorporating this into the equations yields the actual tooth surface:

$$r_1 = r_1(u_1, \beta_1, \phi, X’)$$

For the gear, which is often produced using the forming method, the tooth surface equations are derived similarly, but with simplified kinematics due to the absence of complex motions. The gear tooth surface and its normal vector in coordinate system $S_2$ are:

$$r_2 = r_2(\mu_2, \theta_2)$$

$$n_2 = n_2(\theta_2)$$

To analyze meshing performance, I employ tooth contact analysis (TCA) by defining coordinate systems for the assembled gear pair: $S_e$ for the gear, $S_h$ as the fixed assembly frame, and $S_1$ and $S_2$ as moving frames attached to the pinion and gear, respectively, rotating about axes $x_h$ and $x_e$. The pinion and gear tooth surfaces in the assembly frame are:

$$r_{h1}(u_1, \theta_1, \phi, \phi_1, X’) = M_{h1} r_1$$

$$n_{h1}(\theta_1, \phi, \phi_1, X’) = L_{h1} n_1$$

$$r_{h2}(u_2, \theta_2, \phi_2, E) = M_{he} M_{e2} r_2$$

$$n_{h2}(\theta_2, \phi_2, E) = L_{he} L_{e2} n_2$$

where $E$ is the offset distance, and $\phi_1$ and $\phi_2$ are the rotation angles of the pinion and gear. The meshing conditions require that the position vectors and normal vectors coincide at contact points:

$$r_{h1}(u_1, \theta_1, \phi, \phi_1, X’) = r_{h2}(u_2, \theta_2, \phi_2, E)$$

$$n_{h1}(\theta_1, \phi, \phi_1, X’) = n_{h2}(\theta_2, \phi_2, E)$$

$$f(u_1, \theta_1, \phi) = n_1 \cdot v_1 = 0$$

This system of equations involves seven unknowns: $u_1$, $\phi_1$, $\theta_1$, $\phi$, $u_2$, $\theta_2$, and $\phi_2$. By fixing one variable and solving numerically, I obtain a series of contact points on the gear tooth surface, which form the contact trajectory. Additionally, the transmission error (TE) is calculated as the deviation from the ideal linear relationship between $\phi_1$ and $\phi_2$, providing insights into meshing smoothness.

In my analysis, I categorize machine adjustment parameters into displacement-type (e.g., vertical wheel position, bed position, axial wheel position, radial blade position) and angle-type (e.g., blade profile angle, blade inclination angle, blade rotation angle, angular blade position, workpiece installation angle). Each parameter’s influence on contact patterns and transmission errors is evaluated by introducing small variations (e.g., ±0.1 mm for displacements, ±0.1° for angles) and observing changes in the TCA results. For instance, a positive change in vertical wheel position shifts the contact trajectory toward the toe on the drive side and the heel on the coast side, while negative changes have opposite effects. Similarly, variations in blade profile angle primarily alter the contact pattern along the tooth height direction, affecting pressure angle and leading to edge contact if errors are large.

To quantify these effects, I summarize the impact on transmission error values in the following table, which shows the percentage deviation from the nominal TE value for both drive and coast sides. The nominal TE values are -12.0 μrad for the drive side and -12.5 μrad for the coast side.

| Parameter | Change | Drive Side TE (μrad) | Coast Side TE (μrad) | Drive Side Deviation (%) | Coast Side Deviation (%) |

|---|---|---|---|---|---|

| Blade Profile Angle | +0.1° | -11.9 | -7.3 | 0.83 | 41.6 |

| Blade Profile Angle | -0.1° | -10.8 | -14.3 | 10.0 | 14.4 |

| Blade Inclination Angle | +0.1° | -12.04 | -15.35 | 0.33 | 22.8 |

| Blade Inclination Angle | -0.1° | -11.22 | -9.1 | 6.5 | 27.2 |

| Vertical Wheel Position | +0.1 mm | -12.05 | -12.42 | 0.42 | 0.64 |

| Vertical Wheel Position | -0.1 mm | -11.96 | -12.54 | 0.33 | 0.32 |

| Bed Position | +0.1 mm | -11.93 | -11.88 | 0.58 | 4.96 |

| Bed Position | -0.1 mm | -12.012 | -12.91 | 0.10 | 3.28 |

| Blade Rotation Angle | +0.1° | -11.48 | -12.9 | 4.33 | 3.2 |

| Blade Rotation Angle | -0.1° | -12.24 | -12.3 | 2.0 | 1.6 |

| Angular Blade Position | +0.1° | -12.0 | -12.0 | 0.0 | 0.0 |

| Angular Blade Position | -0.1° | -12.0 | -12.0 | 0.0 | 0.0 |

| Axial Wheel Position | +0.1 mm | -12.13 | -12.34 | 1.08 | 1.28 |

| Axial Wheel Position | -0.1 mm | -11.86 | -12.5 | 1.20 | 0.0 |

| Radial Blade Position | +0.1 mm | -11.99 | -9.55 | 0.08 | 23.6 |

| Radial Blade Position | -0.1 mm | -10.55 | -14.3 | 12.08 | 14.4 |

| Workpiece Installation Angle | +0.1° | — | -11.0 | — | 12.0 |

| Workpiece Installation Angle | -0.1° | -11.655 | -13.2 | 2.88 | 5.6 |

From this analysis, I observe that displacement-type parameters mainly affect the contact trajectory along the tooth length direction, with radial blade position having the most significant impact, followed by vertical wheel position, bed position, and axial wheel position. For transmission errors, radial blade position also shows the largest influence, particularly on the coast side, where deviations exceed 20% for negative changes. Angle-type parameters, such as blade profile angle and blade inclination angle, affect both tooth length and height directions, with blade profile angle causing the most substantial changes in TE values. Angular blade position, however, has negligible effects, highlighting its stability in machining processes.

To further understand the tooth surface modifications, I develop a tooth surface mismatch analysis by comparing the actual tooth surface with a reference surface. The mismatch amount $m_{ij}^k$ at grid points is defined as:

$$m_{ij}^k = (r_{ij}^k – r_{ij}^1) \cdot n_{ij}^1$$

where $r_{ij}^1$ and $n_{ij}^1$ are the position and normal vectors of the reference surface, and $r_{ij}^k$ is for the analyzed surface. By plotting these mismatches, I visualize how parameters like blade profile angle, radial blade position, and workpiece installation angle alter the tooth profile. For example, a positive change in blade profile angle on the drive side increases the pressure angle, shifting the contact toward the toe and tip, while on the coast side, it affects both spiral angle and pressure angle, moving the contact along the length and height. Radial blade position variations predominantly change the spiral angle, influencing the contact pattern along the tooth length, and installation angle adjustments impact pressure angle and spiral angle, with coast side effects being more pronounced. The mismatch is generally larger at the toe compared to the heel, and symmetric for positive and negative changes, confirming the consistency of parameter effects.

In conclusion, my study demonstrates that machine tool adjustment parameters play a crucial role in determining the meshing performance of hypoid gears. Displacement-type parameters primarily influence the contact trajectory along the tooth length, while angle-type parameters affect both length and height directions, with some, like radial blade position and blade profile angle, having dominant effects on transmission errors and contact patterns. The mismatch analysis corroborates the TCA results, showing how parameter deviations lead to tooth profile changes that can cause edge contact or reduced meshing quality. These findings provide a theoretical foundation for optimizing hypoid gear manufacturing processes, enabling better control over contact behavior and transmission accuracy. Future work could incorporate material properties and thermal effects to further enhance the predictive capabilities of the models.

The mathematical models and analysis methods presented here offer practical guidance for adjusting machine parameters during hypoid gear production, ultimately contributing to longer service life and lower noise in applications. By continuously refining these approaches, I aim to support advancements in gear technology that meet the demanding requirements of modern industries. The integration of TCA with mismatch evaluation forms a comprehensive framework for quality assurance, ensuring that hypoid gears perform reliably under various operational conditions.