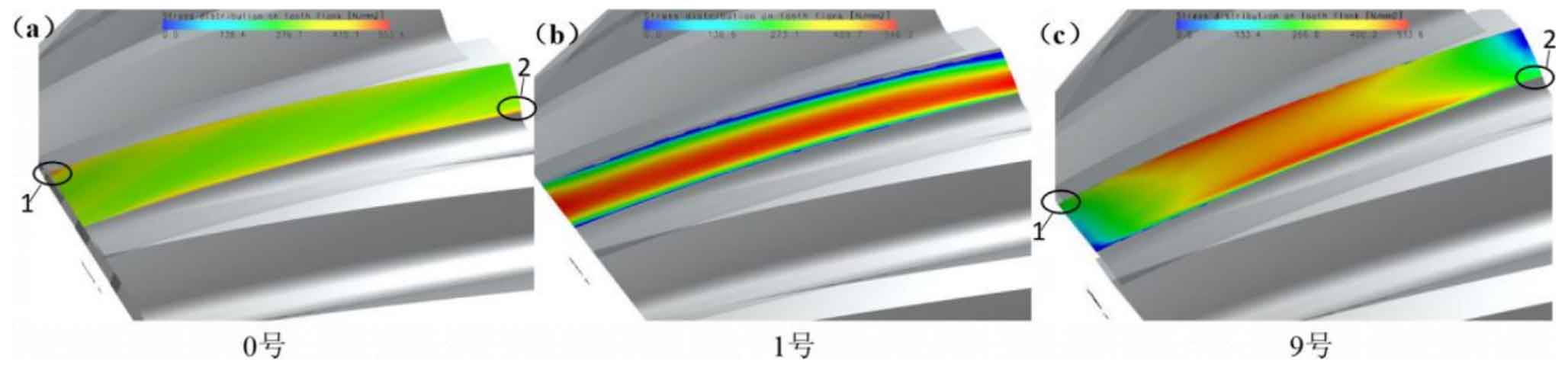

As shown in the figure, the tooth surface load distribution of No. 0 unmodified, No. 1 optimized and No. 9 optimized plans is the three-dimensional contact pattern.

From Figure (a), it can be found that there is a large load and uneven distribution around the tooth top and tooth root of the unmodified helical gear, especially the load distribution at the sharp and weak parts such as 1 and 2 is red, which is easy to cause the gear to wear or even break due to the eccentric load of the gear teeth during meshing transmission, and the final service life and meshing stability are reduced. At first glance, the No. 1 optimization scheme (Fig. (b)) seems to have more serious loads (the red part becomes more), but these loads are mainly concentrated in the middle of the gear teeth with larger load capacity, and gradually spread to the vulnerable tooth top and root, and the maximum value of the tooth surface load has decreased, which will help to reduce the sudden change of the tooth surface load to a certain extent, thus improving the gear mesh transmission performance. As the No. 9 optimization scheme adopts the compound modification of tooth direction and drum shape, the load is evenly distributed from the center of the gear tooth width along the axis in both directions, which significantly improves the load distribution of such sharp and weak parts as 1 and 2.