Under ideal oil-lubricated meshing conditions, the big and small gear teeth will be completely separated by the oil film. At this time, the two tooth surfaces do not contact and the friction coefficient is very small, and there will be no scuffing or wear. However, in the actual meshing process, if the elastic hydrodynamic oil film between the teeth is thin, the two gears will inevitably contact directly, which may lead to tooth surface wear and scuffing. Because the scuffing failure is transient compared with pitting and fatigue fracture with obvious development cycle, it is necessary to avoid the scuffing failure of gears through flash temperature research.

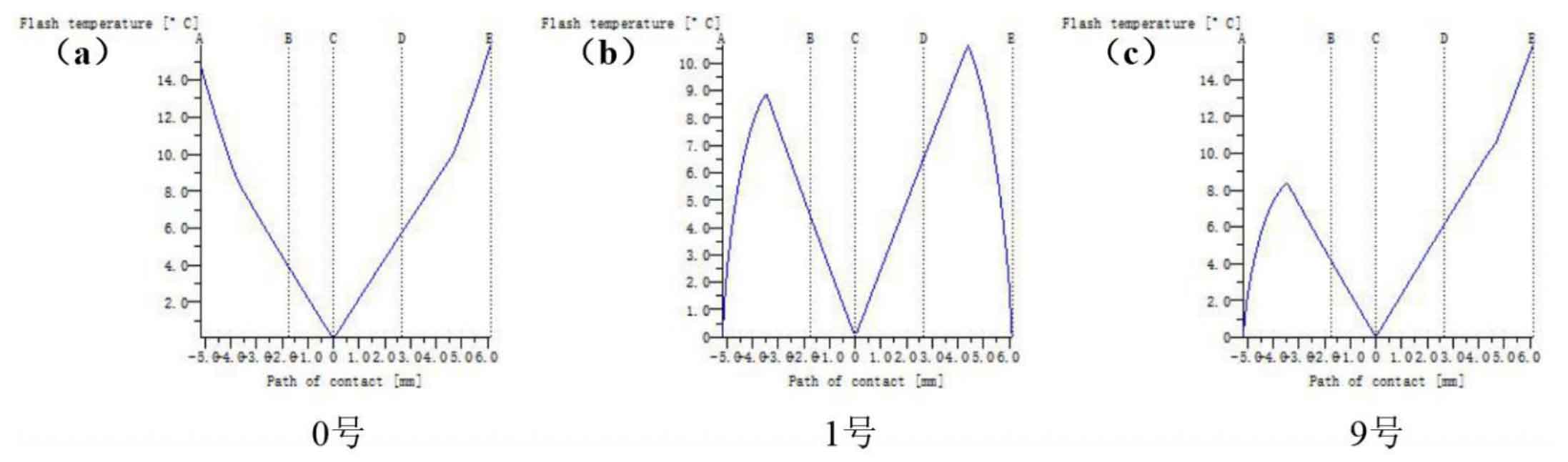

Figure 1 shows the flash temperature curve of the helical gear pair in the 0 # unmodified, 1 # optimized and 9 # optimized scheme. It can be seen that the flash temperature of the helical gear pair after the modification in the 1 # optimized scheme has decreased substantially, with the peak temperature decreasing from 15.85 ℃ before the modification to 10.62 ℃ after the modification, and 5.23 ℃; While the flash temperature peak temperature of the meshing section (CE) of the helical gear pair modified by the No. 9 optimization plan did not decrease, but the meshing section (AC) of the helical gear pair decreased significantly as a whole. This is because a pair of gears will first mesh at the root of the driving gear and the top of the driven gear, while the No. 9 optimization plan is to use the top modification of the driven gear to improve its meshing performance. Therefore, it can be considered that the instantaneous meshing temperature of the helical gear pair after optimization and modification is significantly reduced, effectively avoiding the occurrence of thermal deformation of tooth profile and gluing failure.

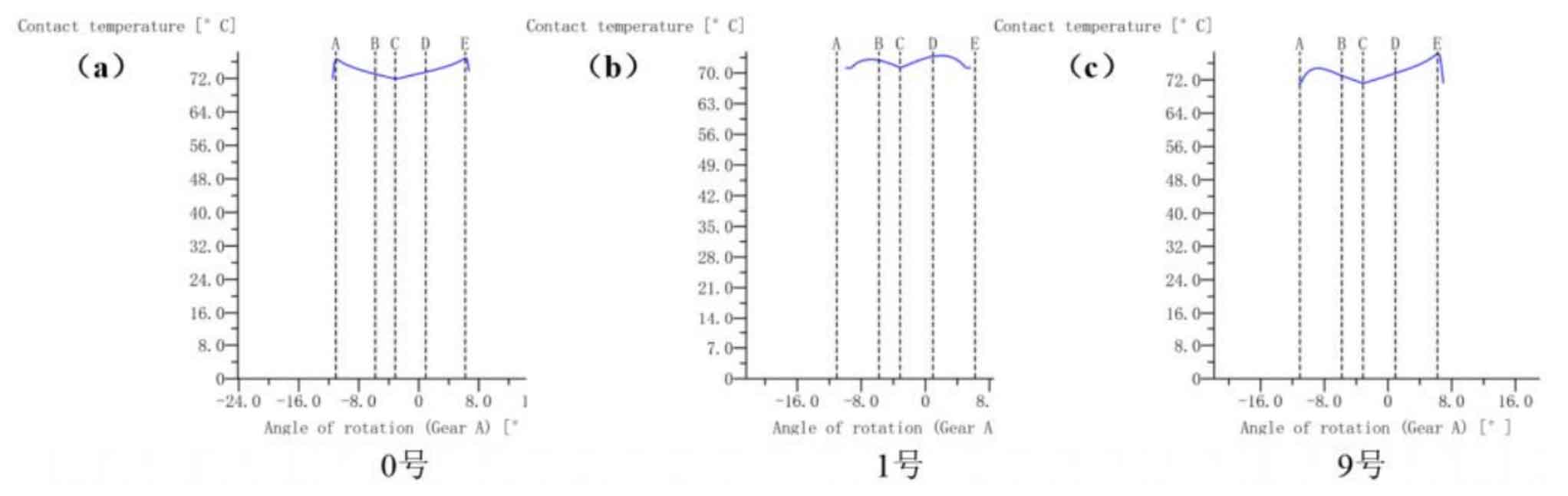

The contact temperature of the tooth surface is the sum of the temperature of the helical gear itself (greatly affected by the lubricating oil temperature and the average flash temperature) and the flash temperature, and is an important indicator reflecting the relative sliding degree of the meshing gear pair. Figure 2 shows the contact temperature curve of the tooth surface of the helical gear pair in the 0 # unmodified, 1 # optimized and 9 # optimized schemes. It can be seen from the figure that the contact temperature of the tooth surface of the helical gear pair after the modification by the No. 1 optimization plan has decreased significantly, with the maximum value of 74.87 ℃, which is 4.6% lower than that before the modification (78.44 ℃); Because the No. 9 optimization scheme only modifies the passive wheel, the temperature of the meshing section (CE) does not decrease, but the temperature of the meshing section (AC) decreases significantly.