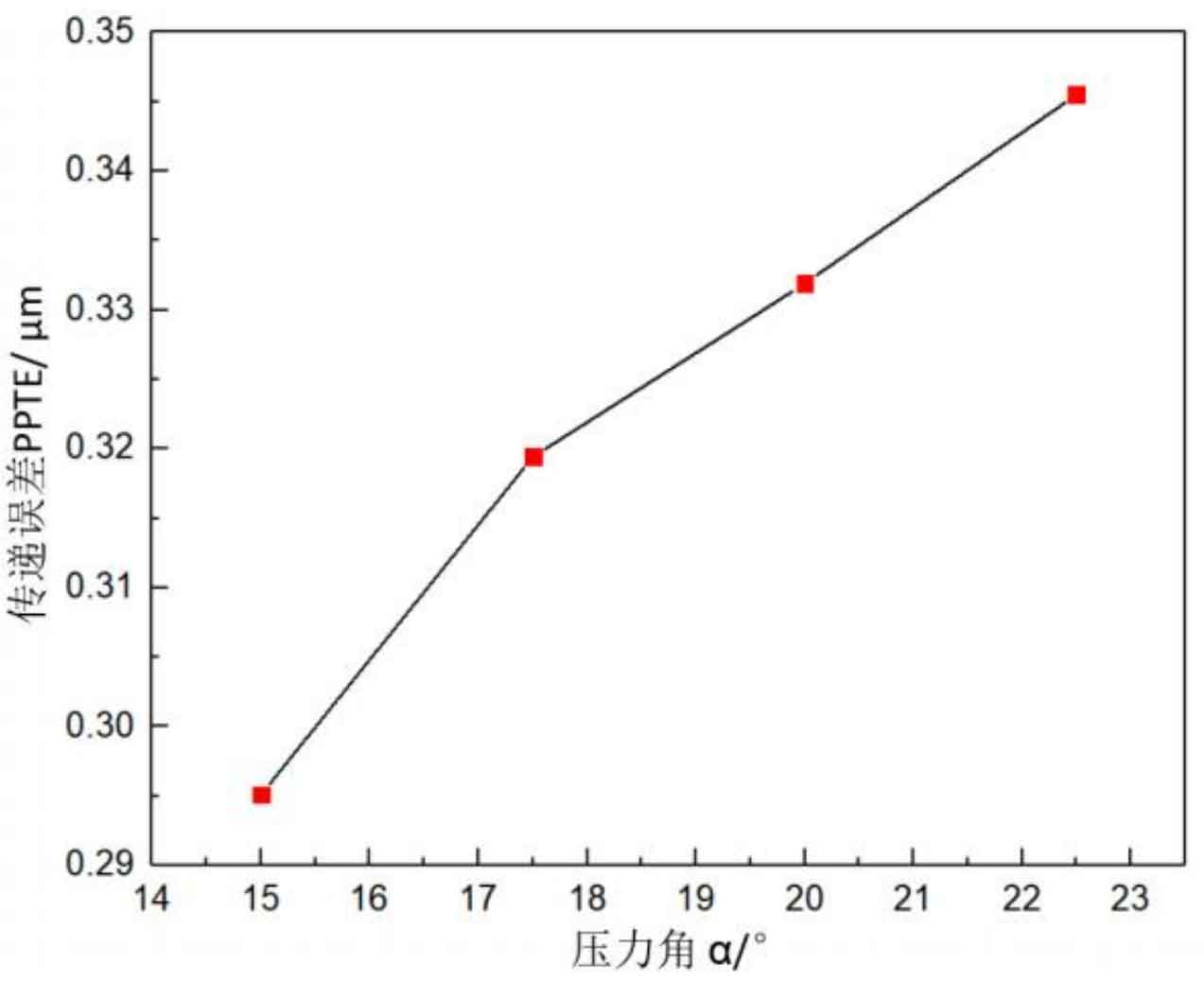

(1) Influence of pressure angle on transmission error of helical gears

Figure 1 shows the relationship curve between pressure angle and transmission error of helical gear. It can be seen that in the range of 15 °~22.5 °, the larger the pressure angle, the greater the transmission error. The minimum transmission error is 0.295 at 15 ° μ m; Highest at 22.5 °, 0.346 μ m。

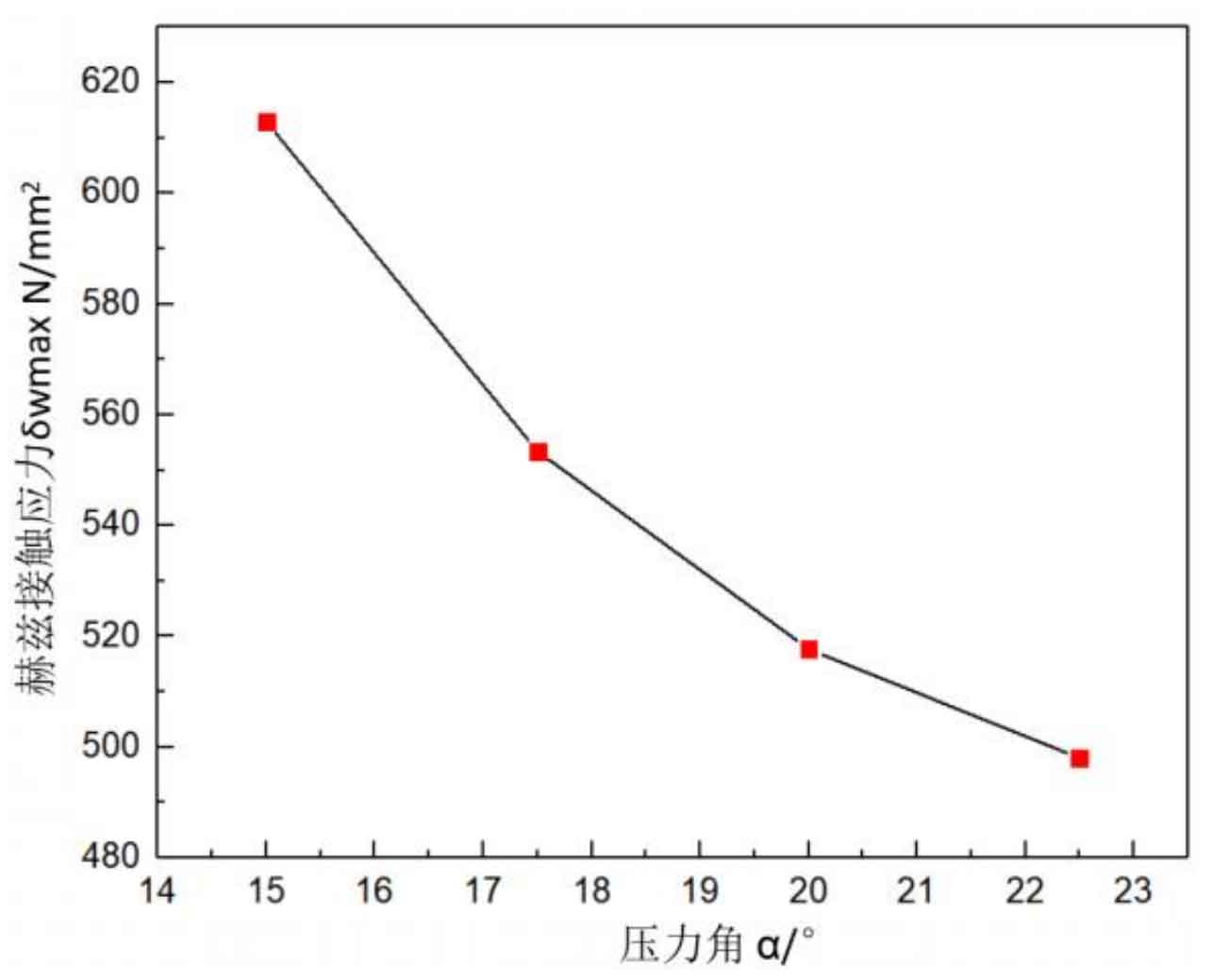

(2) Influence of Pressure Angle on Hertz Contact Stress of Helical Gears

Figure 2 shows the Hertz contact stress relationship curve between the pressure angle and the helical gear pair. It can be seen that within the range of 15 °~22.5 °, the Hertz contact stress decreases with the increase of the pressure angle, and is the lowest at 22.5 °, 498.013N/mm2.

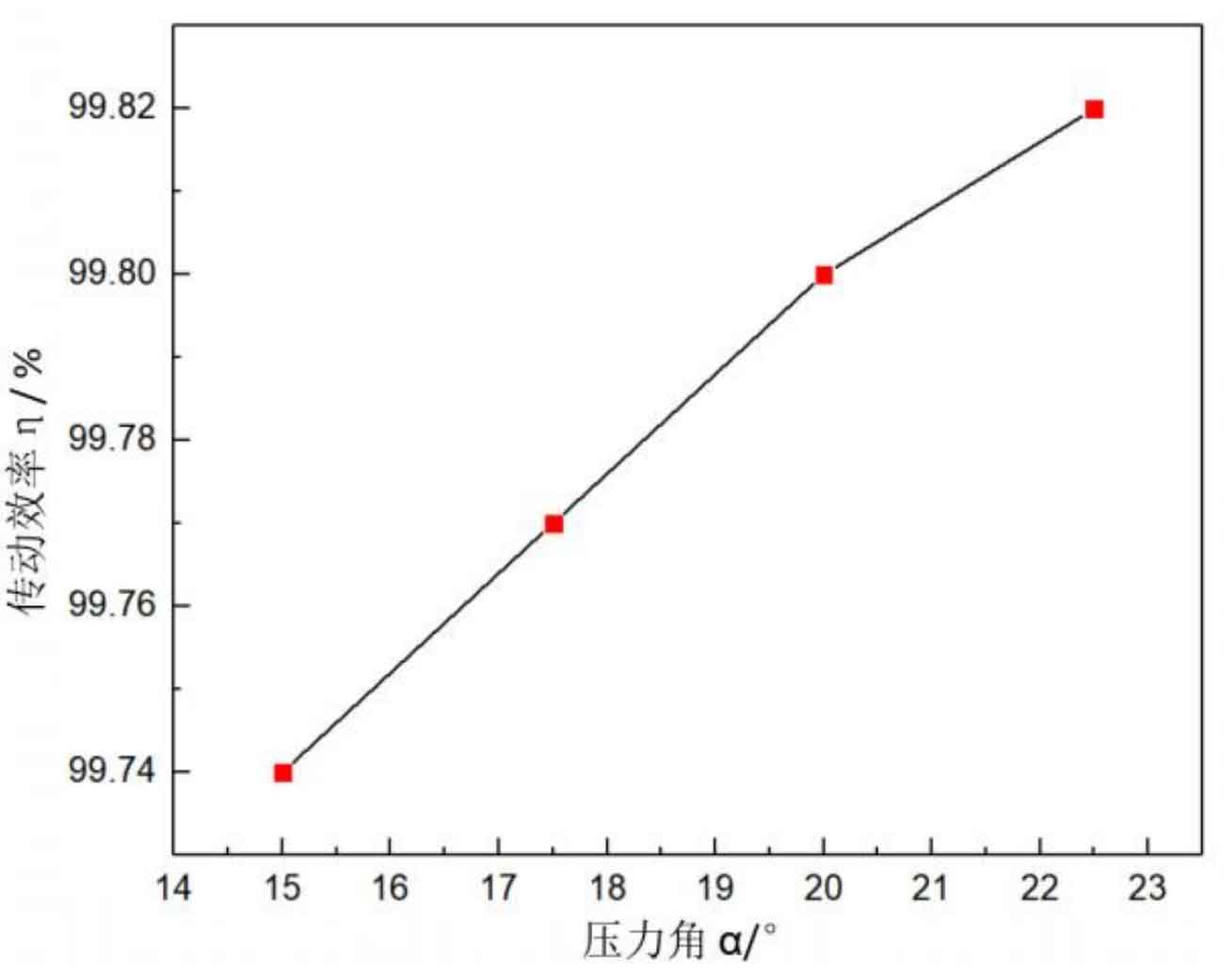

(3) Influence of Pressure Angle on Helical Gear Transmission Efficiency

Figure 3 shows the relationship curve between pressure angle and helical gear transmission efficiency. It can be seen that the transmission efficiency of helical gear increases with the increase of pressure angle within this range.

To sum up, when the pressure angle changes within the range of 15 °~22.5 °, the Hertz contact stress will further decrease with the increase of the pressure angle, and the transmission efficiency will also be improved, but the transmission error will increase. Therefore, if the noise tolerance is high in engineering practice and the strength (life) of helical gears is in urgent need of improvement, the pressure angle can be appropriately increased.