The selection of pressure angle is directly related to the transmission quality of helical gear pair. The greater the pressure angle, the greater the power consumption, and the harder the transmission; On the contrary, it will save more effort.

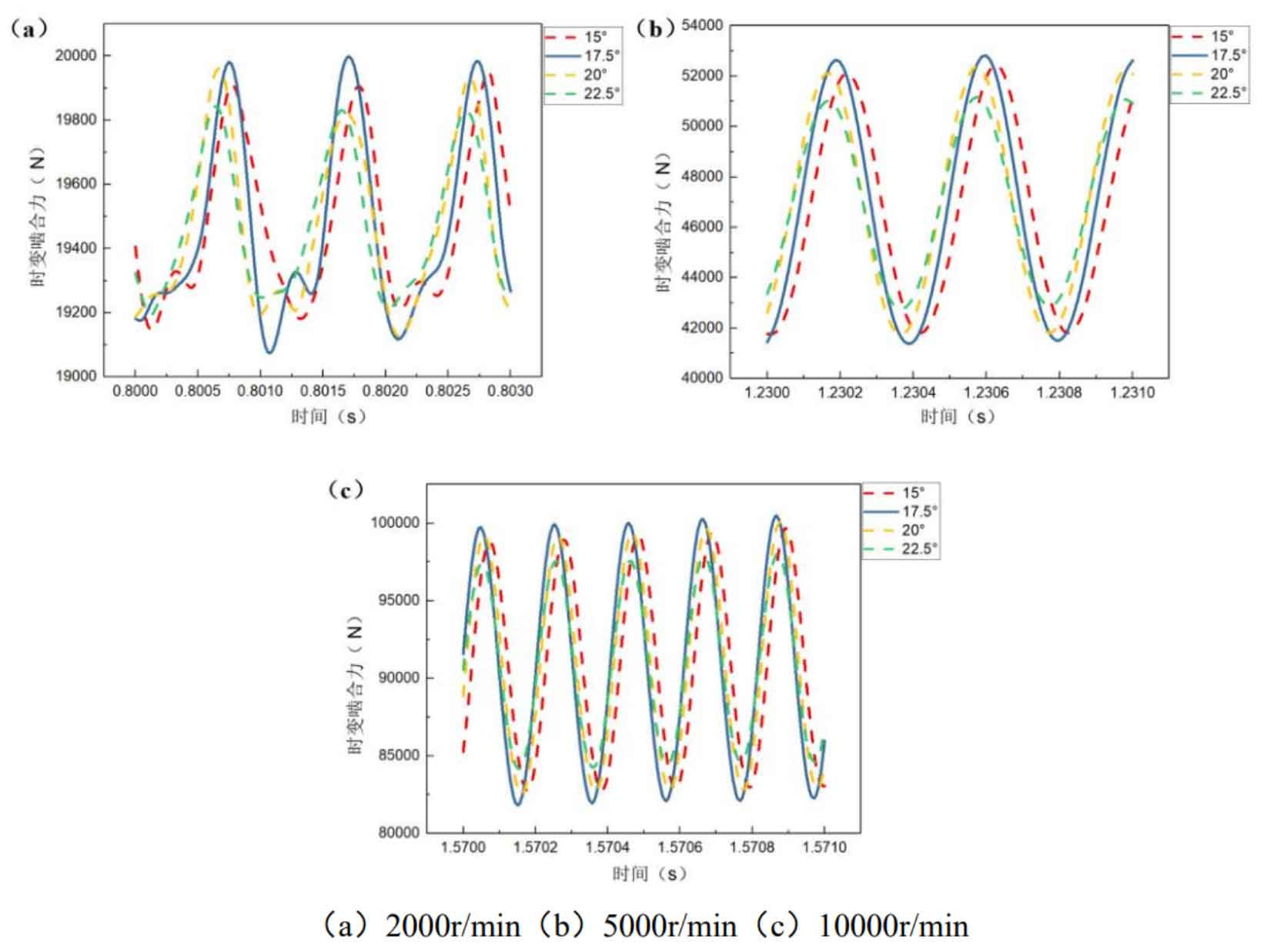

The influence curve of the pressure angle on the time-varying meshing force of the helical gear pair at different speeds is shown in Figure 1. It can be seen that the time-varying meshing force of the helical gear first increases and then decreases as the pressure angle increases. When the pressure angle is 17.5 °, the time-varying meshing force of the helical gear is the largest, and the meshing is not smooth at low speed (2000r/min), with obvious meshing impact; However, an appropriate pressure angle (22.5 °) can not only significantly reduce the time-varying meshing force of the helical gear, but also improve the meshing in and out impact of the helical gear pair (the curve is more smooth), making the transmission more stable.

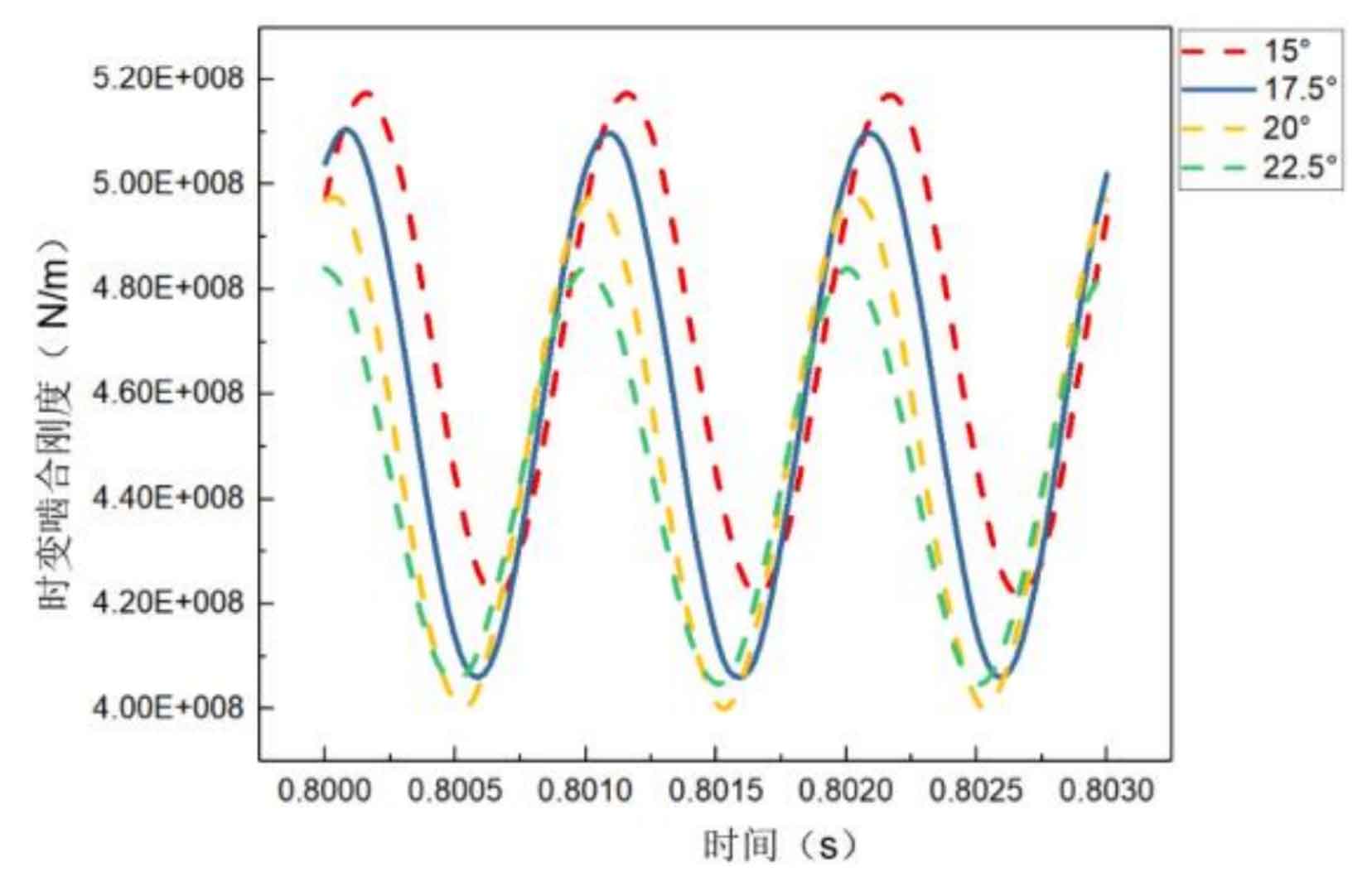

Figure 2 shows the influence curve of the pressure angle on the time-varying meshing stiffness of the helical gear pair. Obviously, the peak value of the time-varying meshing stiffness of the helical gear decreases with the increase of the pressure angle.

To sum up, if only to reduce the dynamic excitation of helical gears, the large pressure angle should be selected on the premise of meeting the time-varying meshing force of small gears.