On ABAQUS software, the meshing process of spiral bevel gear is divided into 200 incremental steps. In the dynamic analysis, the dynamic transmission error of spiral bevel gear is calculated by setting different resistance moments for the large wheel and different rotating speeds for the small wheel.

According to the actual load, three different resistance moments (50 N · m, 150 n · m, 250 n · m) are loaded on the big wheel, and the small wheel speed is constant at 20 rad / s.

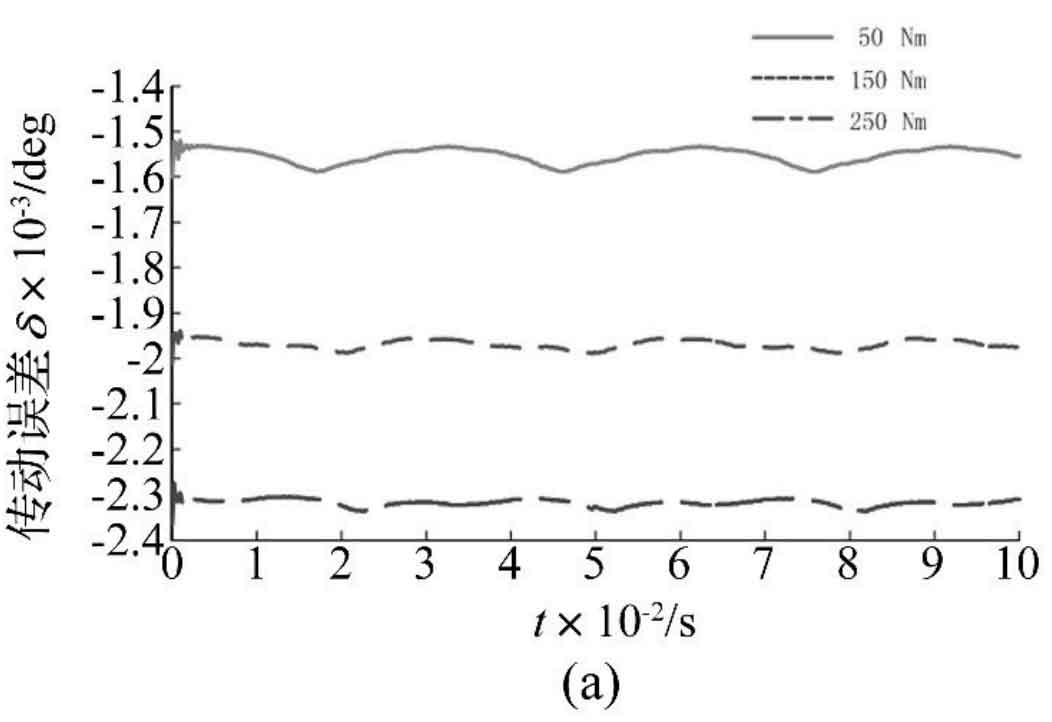

1.Dynamic transmission error curves of two tooth surfaces

By extracting the output results of ABAQUS historical variables, the change of transmission error with time can be obtained. Fig. 1 (a) shows the change of dynamic transmission error with time when the pure theoretical tooth surface is meshed, and Fig. 1 (b) shows the change of dynamic transmission error with time when the real tooth surface of large wheel is meshed with the theoretical tooth surface of small wheel.

It can be seen from Figure 1: ① the transmission error of spiral bevel gear changes with the rotation of small wheel. In the initial stage of spiral bevel gear meshing, the transmission error fluctuates violently up and down, and tends to be flat after a short time; ② The absolute value of dynamic transmission error increases with the increase of load; ③ The dynamic transmission error changes periodically with time.

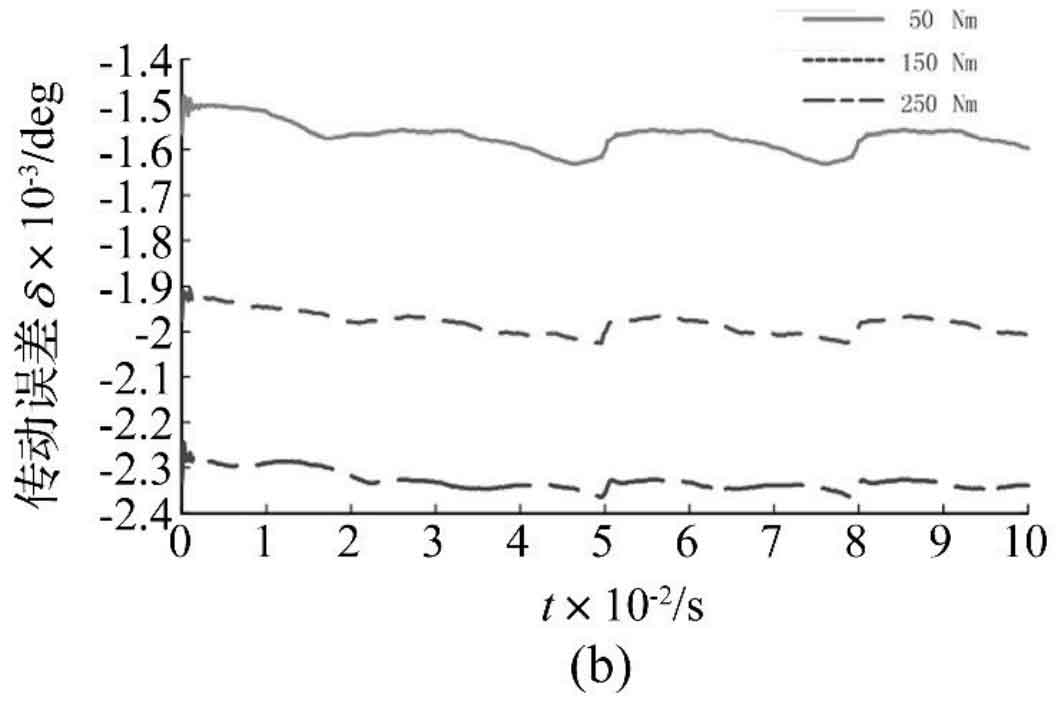

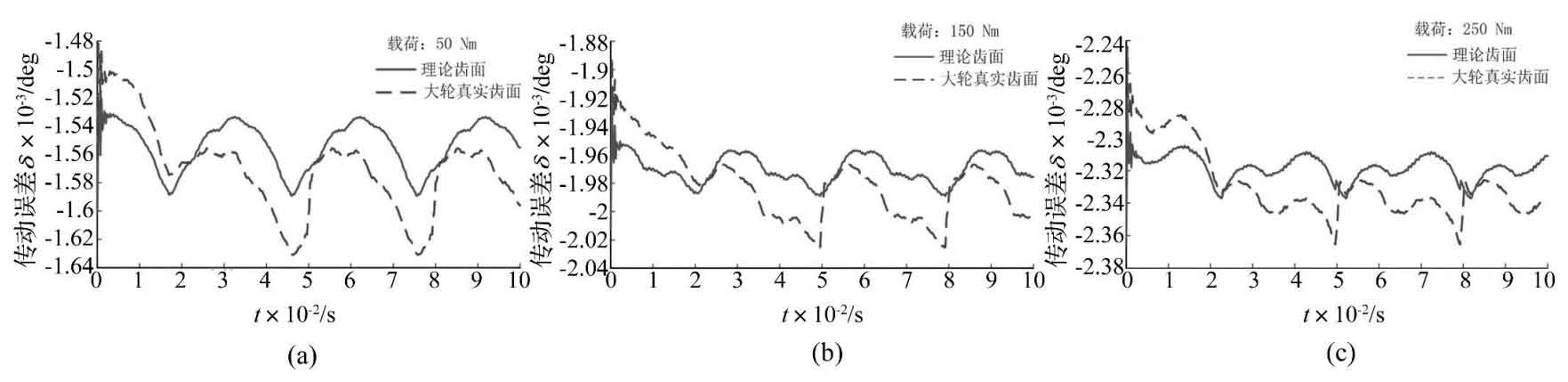

2.Comparison of dynamic transmission errors of two tooth surfaces

Under three different loads, the transmission errors obtained by two different tooth surfaces are compared. Fig. 2 (a) shows the transmission error curves of two tooth surfaces when the load is 50 N · M. Fig. 2 (b) shows the transmission error curves of two tooth surfaces when the load is 150n · M. Fig. 2 (c) shows the dynamic transmission error curves of two tooth surfaces when the load is 250 n · M.

By analyzing and comparing the transmission error curves of two kinds of tooth surface meshing, it can be obtained:

(1) at the initial stage of spiral bevel gear meshing, the transmission error curve fluctuates violently, but tends to fluctuate stably in a very short time. Moreover, before 0.022s of spiral bevel gear meshing contract, the absolute value of dynamic transmission error of real tooth surface meshing of large wheel is less than that of pure theoretical tooth surface meshing. This is due to the different meshing positions of spiral bevel gears at the beginning of meshing and the different size of tooth side clearance, which is not the focus of research.

(2) after the spiral bevel gear meshing is stable, under the given torque, the absolute values of the peaks and troughs of the transmission error curve of the real tooth surface meshing of the large wheel are greater than the absolute values of the peaks and troughs of the pure theoretical tooth surface meshing.