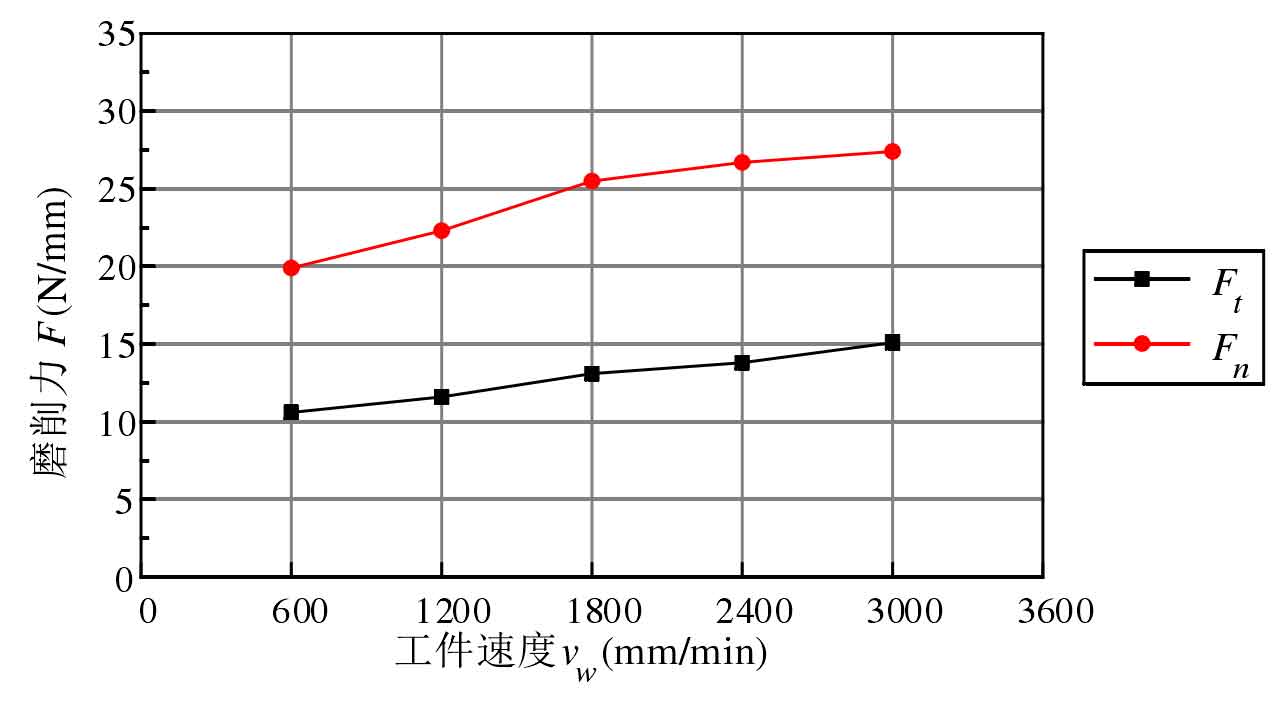

Fixed grinding speed vs = 20.3 M / s, grinding depth AP = 50 μ m. The test is carried out at different spiral bevel gear speeds VW. The influence of spiral bevel gear speed on grinding force is shown in the figure.

It can be seen from the figure that the normal grinding force and tangential grinding force gradually increase with the increase of the speed of the spiral bevel gear. This is because with the increase of the speed of the spiral bevel gear, the maximum cutting depth and material removal rate of a single abrasive particle increase, which increases the load borne by a single abrasive particle. At the same time, because the maximum cutting depth of a single abrasive particle increases, although the number of abrasive particles participating in grinding per unit length of spiral bevel gear decreases, on the whole, the number of effective abrasive particles participating in machining increases. These reasons together lead to an increasing trend of grinding force with the increase of spiral bevel gear speed.