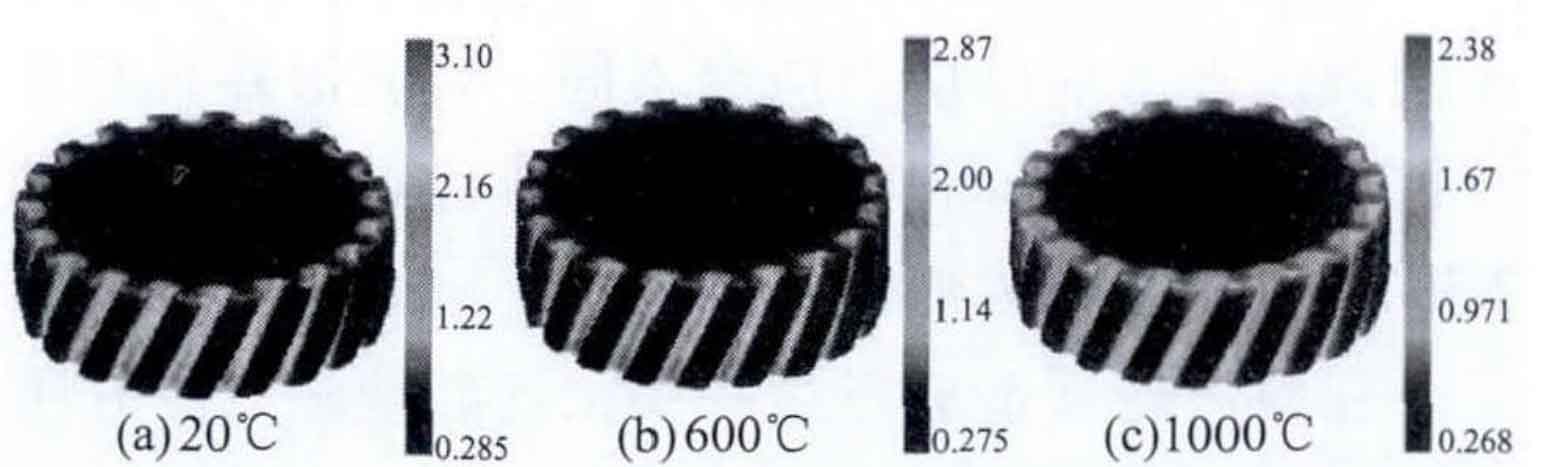

The strain of helical gear forging is different under different blank temperature. Figure 1 shows the strain distribution of blank under different forging temperatures. In order to analyze the influence of forging temperature on helical gear forging process, the temperatures of 20 (room temperature), 600 and 1000 ℃ are selected respectively. At room temperature, the helical gear forging process is a cold closed die forging process. However, due to the helical gear forging process, the metal forging deformation resistance is great and the material flow is difficult in the forming process, resulting in incomplete forming, which makes it difficult for the blank metal to completely fill the cavity. When the blank temperature is 20 ℃, the outer end strain of helical gear forging is about 0.285 and the tooth root strain is about 1.2; When the blank temperature is 600 ℃, the outer end strain is about 0.268 and the tooth root strain is about 0.9; When the blank temperature is 1000 ℃, the outer end strain is about 0.275 and the tooth root strain is about 1.1; The forging strain of helical gear decreases first and then increases.

The cylindrical blank with higher temperature, i.e. 600 ℃ and 1000 ℃, was used for closed helical gear die forging. Because the blank is at a high temperature, the forging pressure and deformation resistance of the blank are small in the process of die forging, and its forming condition is much easier than that of cold forging at room temperature.

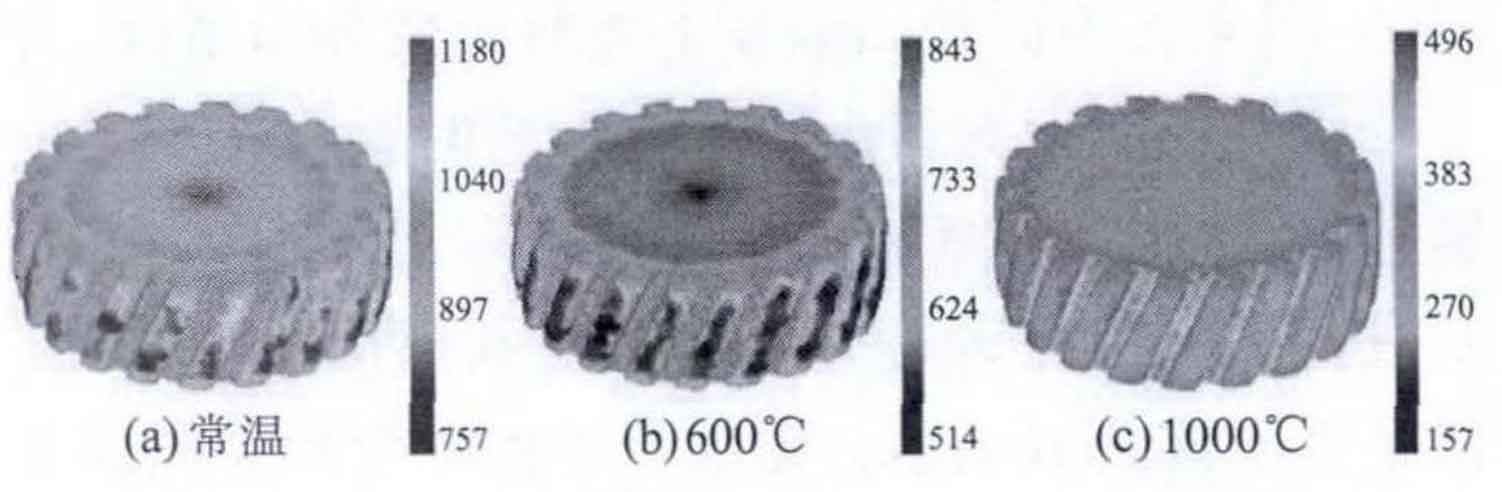

The stress of helical gear forging is different under different blank temperature. Figure 2 shows the stress distribution of blank under different forging temperatures. It can be seen from the figure that when the blank temperature is 20 ℃, the stress distribution at the outer end is about 890 MPa and the tooth root strain is about 1000 MPa; When the blank temperature is 600 ℃, the stress distribution at the outer end is about 550 MPa and the tooth root strain is about 730 MPa; When the blank temperature is 1000 ℃, the stress distribution at the outer end is about 300 MPa and the tooth root strain is about 600 MPa. The stress distribution decreases with the increase of blank temperature. The friction resistance of the forging at the root circle is large, the deformation is the largest and the stress is the largest; The stress at the tooth top circle is relatively small because the friction resistance is less than that at the tooth root circle, the helical gear forging is full, and the metal fills the tooth slot completely. The stress on the upper surface of helical gear forging is small because its upper surface is in contact with the punch and the deformation is small.

It can be seen from the figure that the equivalent stress is similar to the equivalent strain and increases gradually along the axial direction. The forging at the tooth root circle receives large friction resistance, maximum deformation and maximum strain; At the tooth top circle, the friction resistance is less than that at the tooth root circle, and the helical gear forging has been formed, the metal filling tooth slot is complete, and the deformation is small, so the stress value is also relatively small.