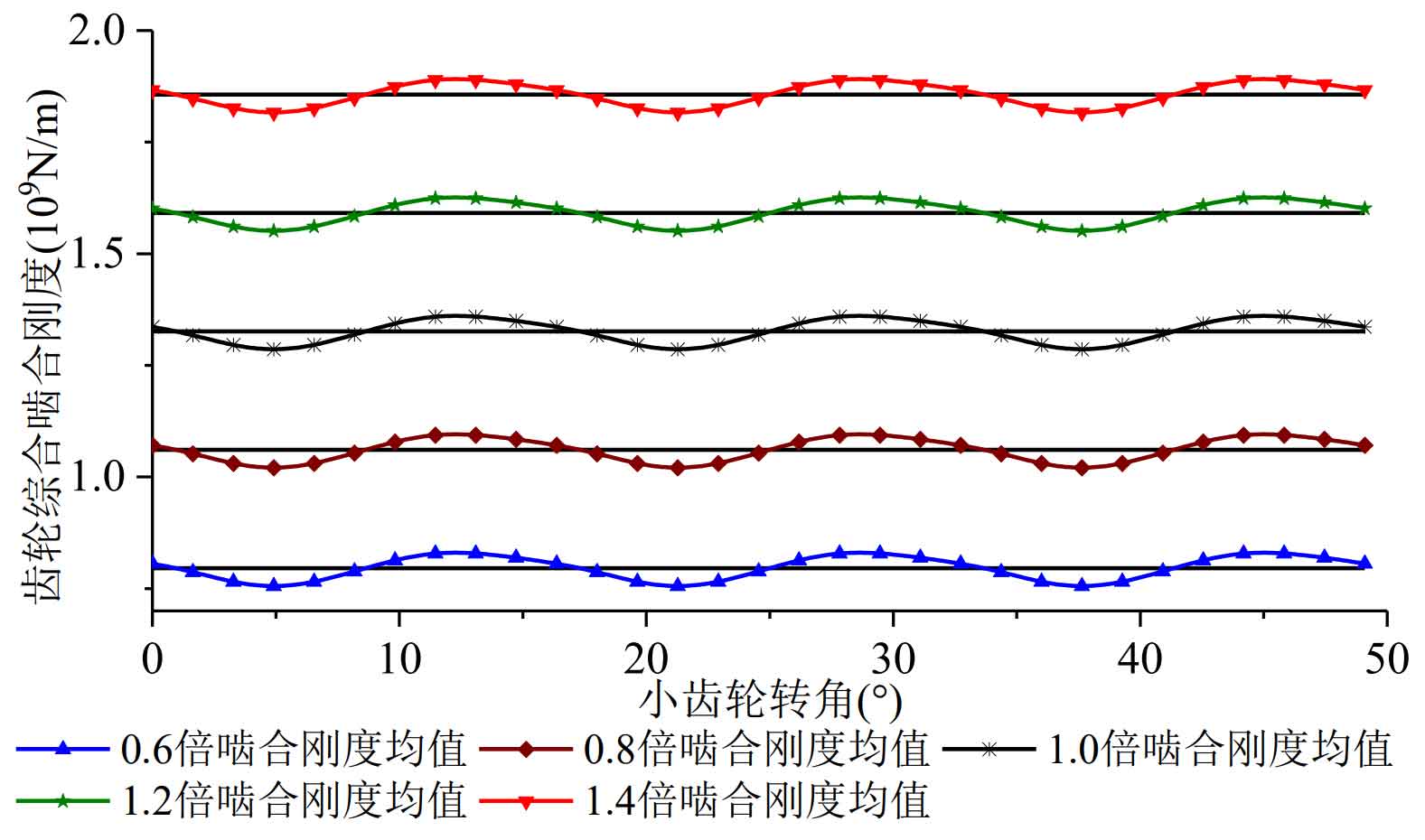

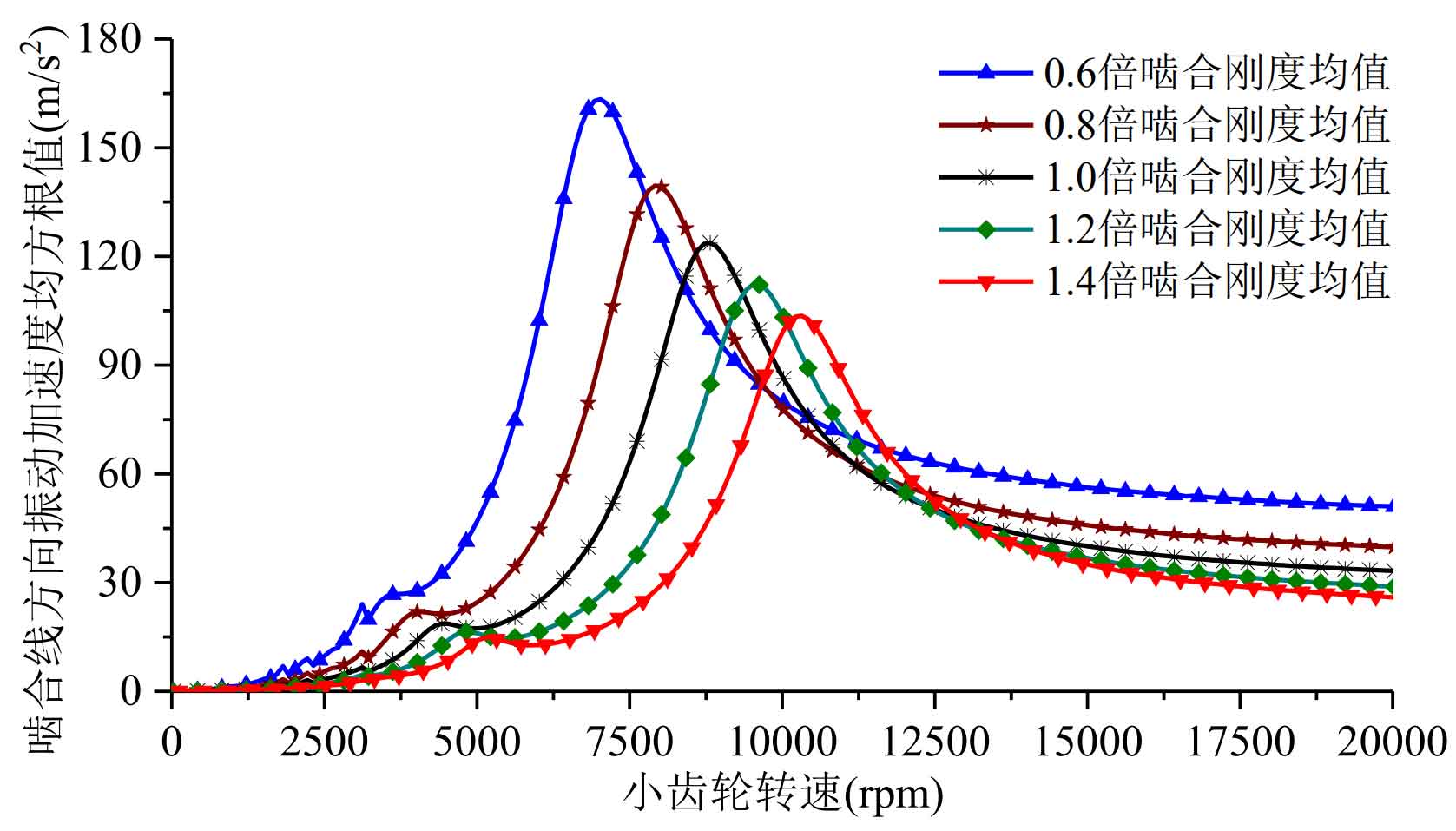

In order to study the influence of the mean value of time-varying meshing stiffness of helical gears on the vibration characteristics of the system, based on the calculated time-varying meshing stiffness curve, take five different time-varying meshing stiffness mean values (0.6 times, 0.8 times, 1.0 times, 1.2 times and 1.4 times) (the amplitude is unchanged, see Figure 1 as the system excitation to obtain the relative vibration acceleration along the meshing line direction of helical gear end face, and the results are shown in Figure 2.

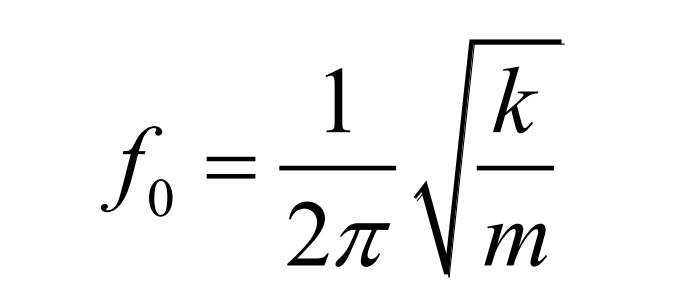

In Figure 2, when the amplitude of time-varying meshing stiffness of helical gear is unchanged, the system vibration response under different mean values of time-varying meshing stiffness is significantly different. In the non resonance region, the root mean square value of the relative vibration acceleration in the direction of helical gear meshing line decreases with the increase of the mean value of helical gear meshing stiffness. It can be clearly seen that the resonant speed of the system has also changed. The resonant speed of the helical gear pair increases with the increase of the mean value of the time-varying meshing stiffness of the helical gear. The numerical change law of the resonant speed conforms to the formula for calculating the natural frequency of the system shown in equation:

Further analysis shows that the reduction of the mean mesh stiffness makes the change rate of the root mean square value of the relative vibration acceleration near the resonance speed of the system larger relative to the speed, which leads to the deterioration of the stability of helical gear vibration when the helical gear speed reaches the resonance speed of the system.

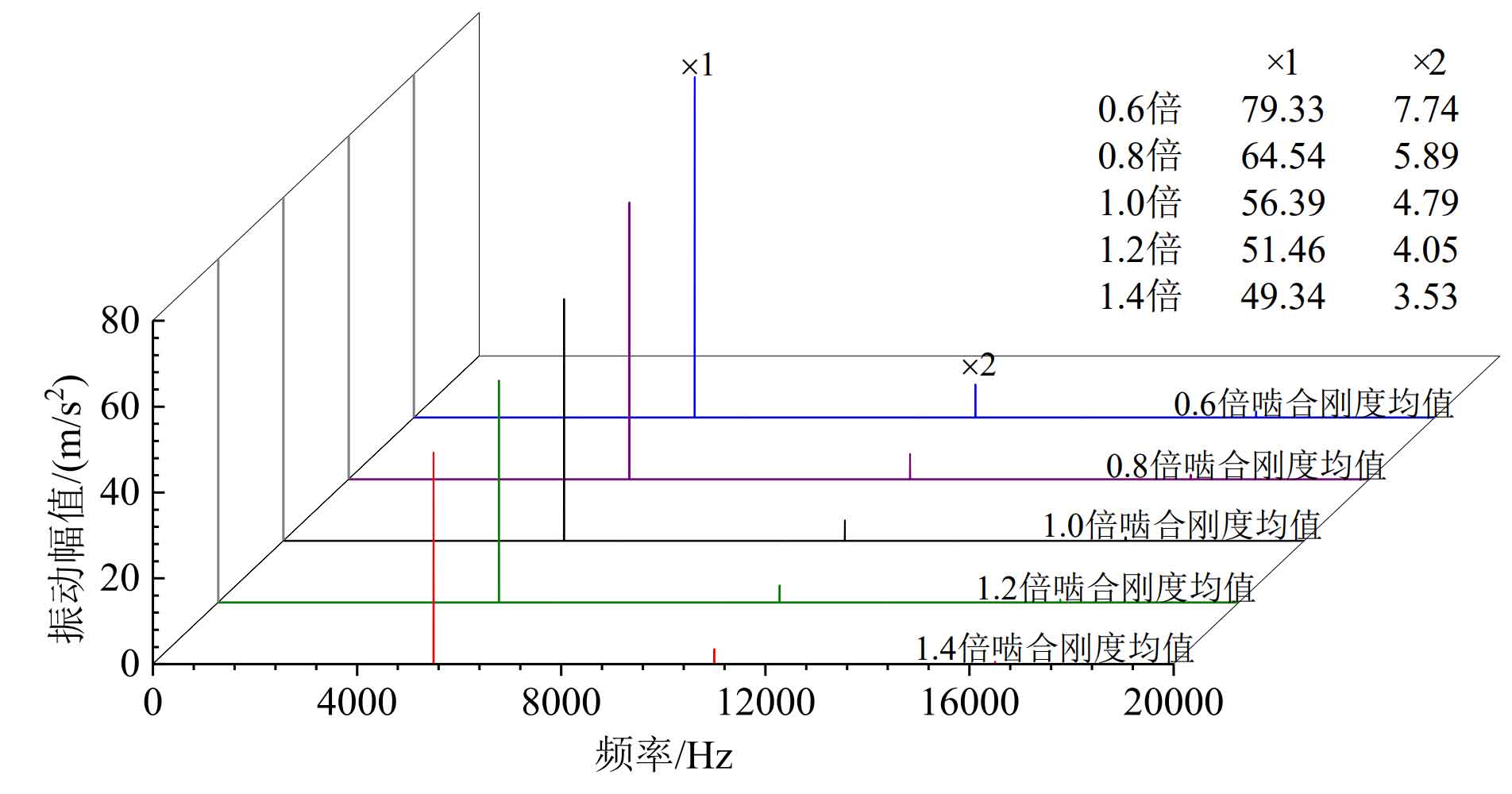

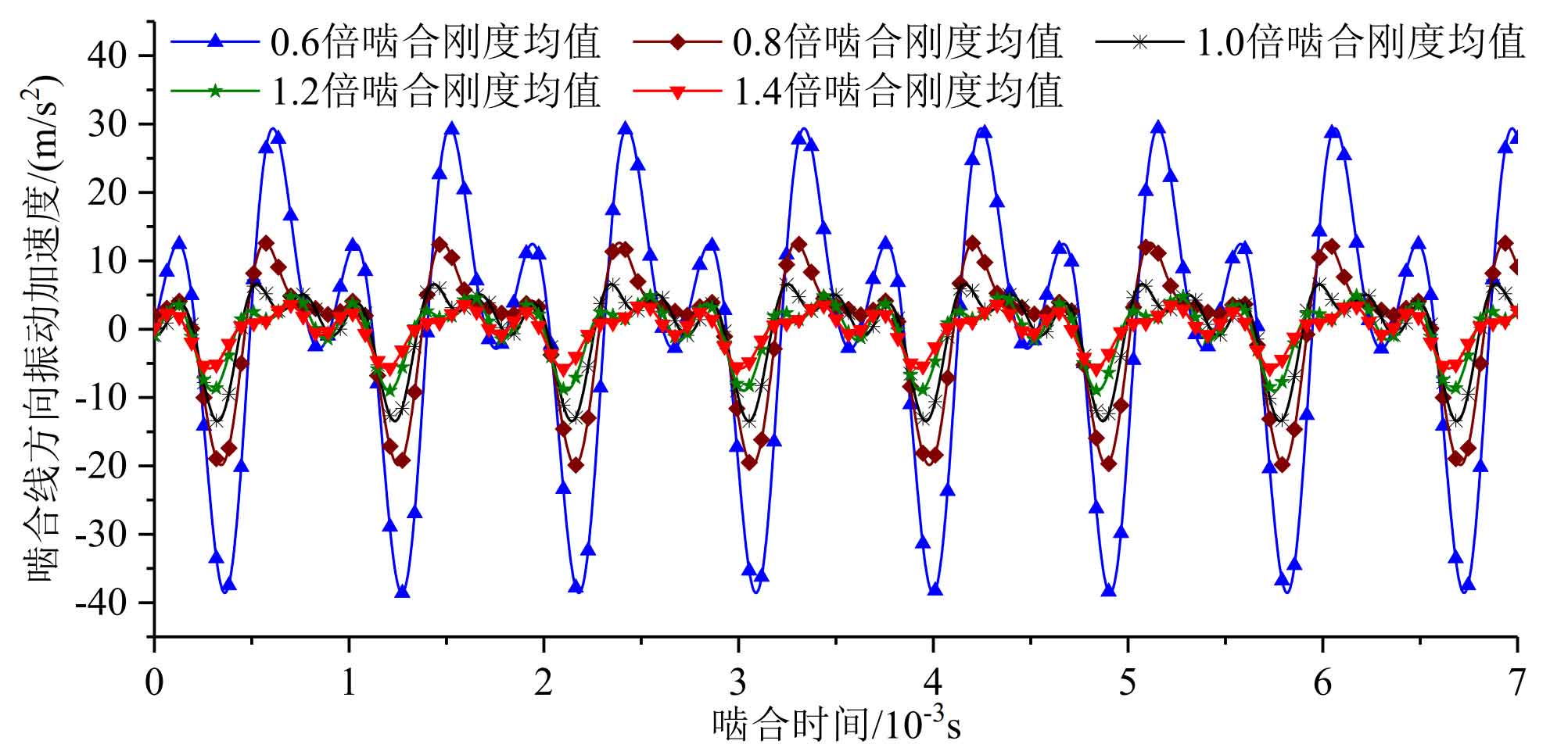

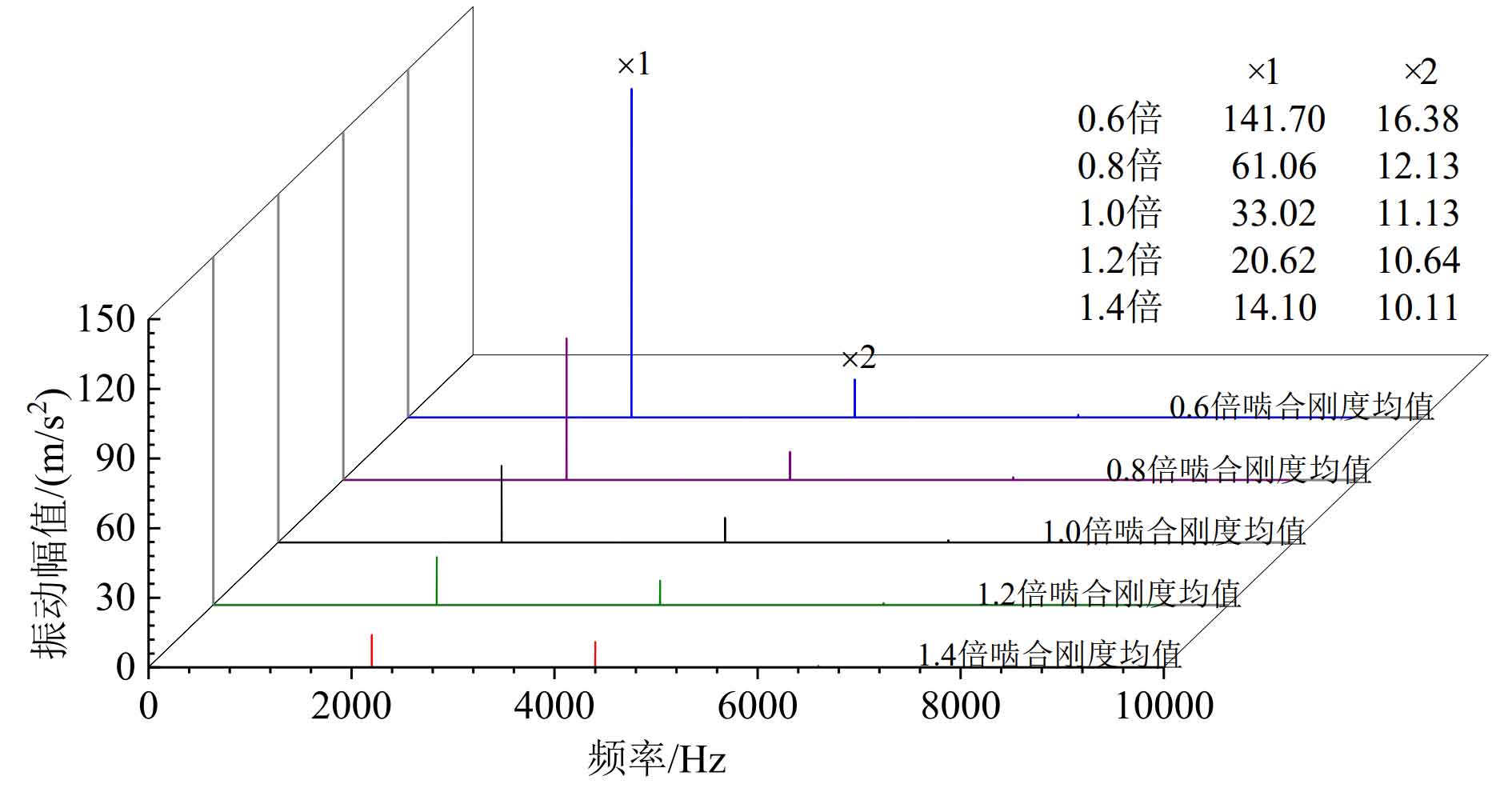

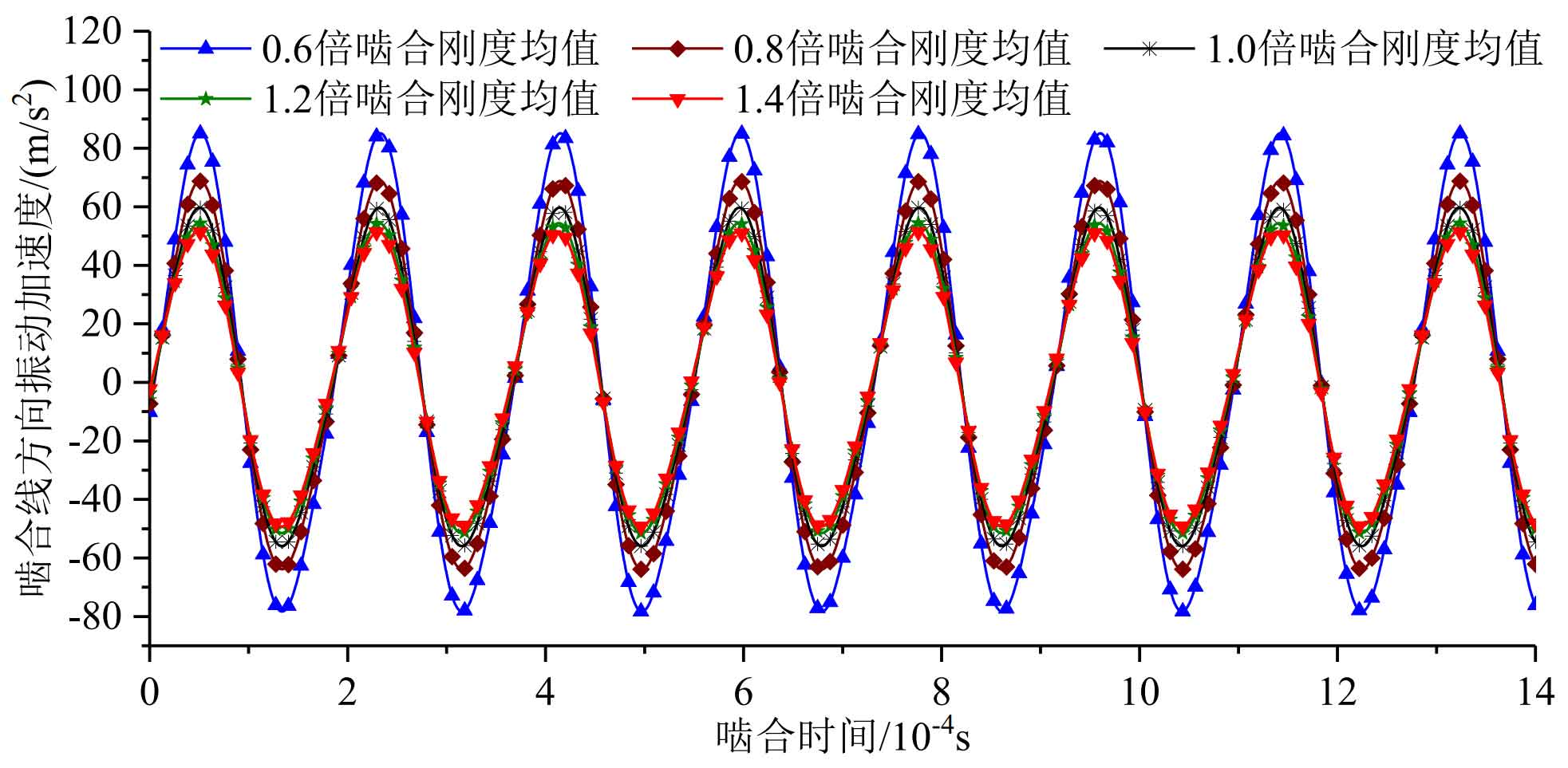

Figure 3 and Figure 5 are the time domain diagrams of the meshing line direction vibration under five different meshing stiffness mean values at 6000rpm and 15000rpm respectively, and their frequency domain diagrams are shown in Figure 4 and Figure 6.

It can be seen from Figure 3 that the larger the mean value of time-varying meshing stiffness is, the smaller the fluctuation of relative vibration acceleration of the system is. Figure 4 shows that the mean value of time-varying meshing stiffness increases, and the amplitude of vibration frequency response decreases. From the specific amplitude of the vibration acceleration in Figure 3 and Figure 4, the amplitude of the system vibration acceleration under the mean value of 0.6 times the meshing stiffness is about 3 times that under the mean value of 1.0 times the meshing stiffness, and the amplitude of the system vibration acceleration under the mean value of 1.0 times the meshing stiffness is about 2 times that under the mean value of 1.4 times the meshing stiffness. The mean value of the helical gear meshing stiffness has a great impact on the system vibration response. This is due to the fact that 6000rpm is close to the resonant speed under the mean mesh stiffness, so the mean mesh stiffness has a significant impact on the vibration response. That is to say, the mean value of time-varying meshing stiffness has more significant influence on the vibration of the system near the resonant speed.

Figure 5 and Figure 6 show the system response at 15,000 rpm under different mean meshing stiffness. It can be seen from the figure that the larger the mean time-varying meshing stiffness is, the smaller the fluctuation of the relative vibration acceleration value of the system is, which is consistent with the analysis results. Different from the analysis, the influence of changing the mean meshing stiffness at 15000 rpm on the vibration response of the system is less obvious than that at 6000 rpm. This is because the system speed is in the over resonance zone, and the speed is far away from the system resonance speed, so the impact is not obvious. That is, in the over resonance region, the influence of the time-varying mesh stiffness mean value on the system is smaller than that in the region near the resonance speed.