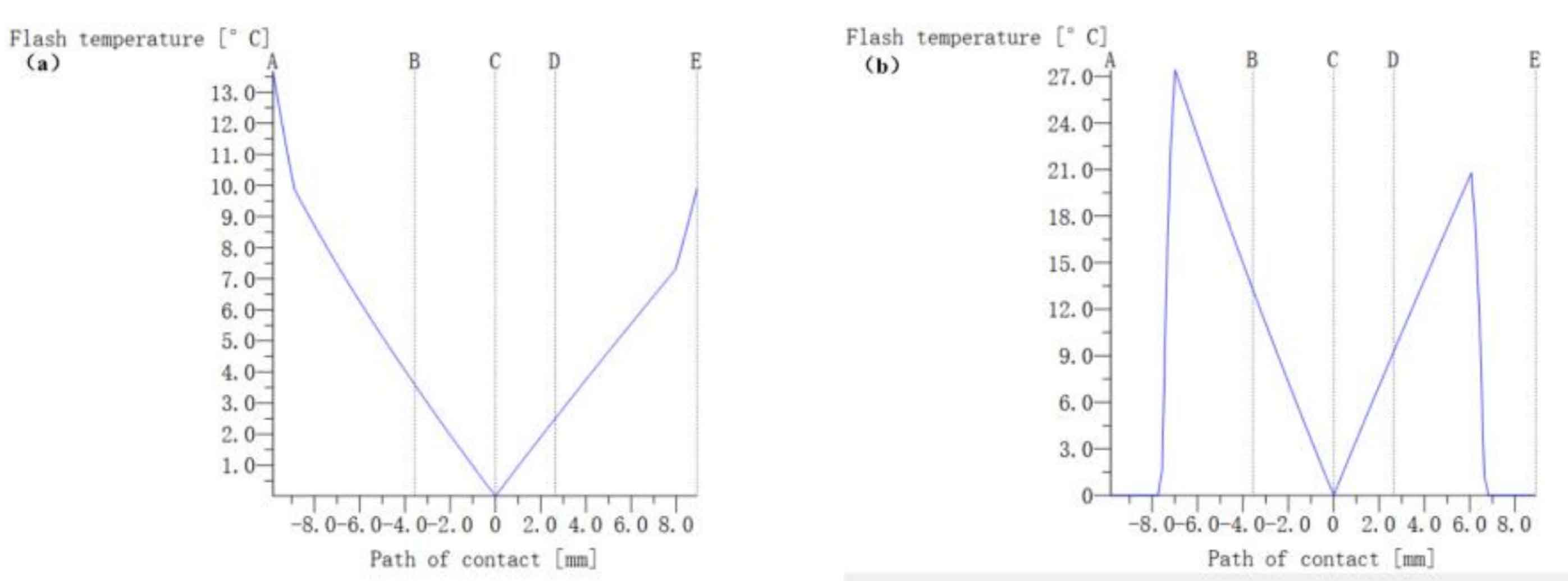

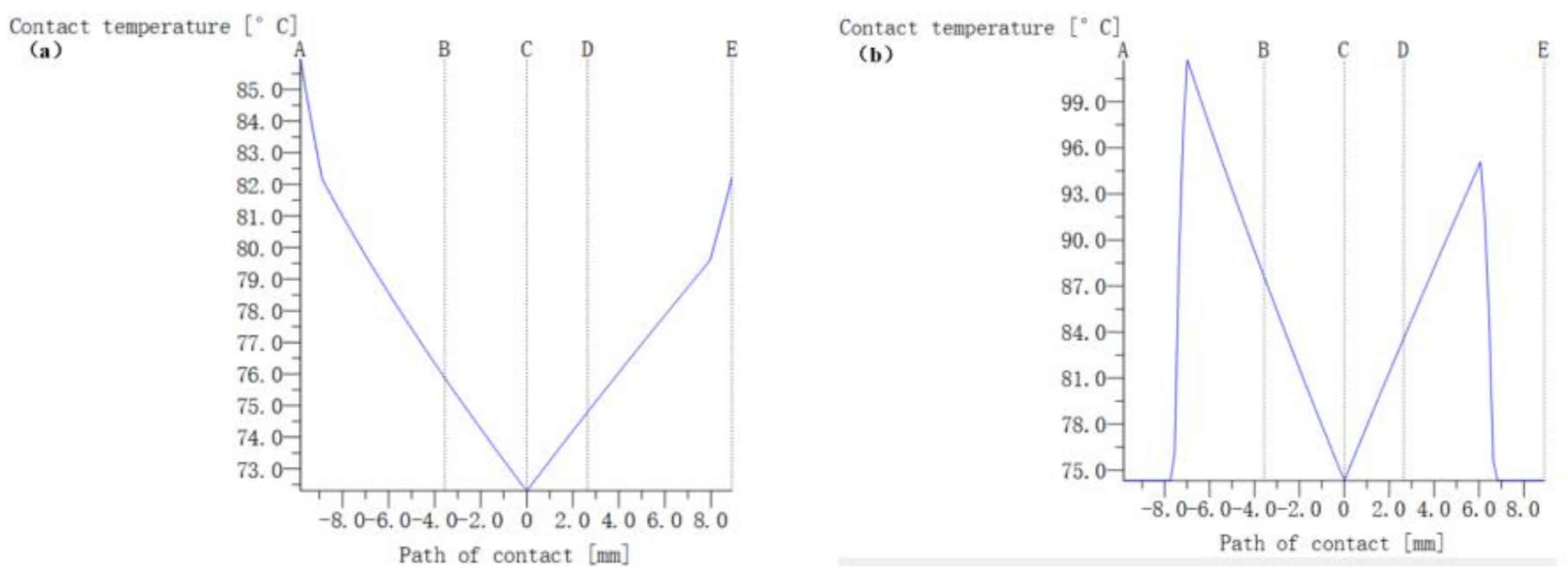

Fig. 1 and Fig. 2 show the flash temperature and contact temperature curves of a helical gear pair before and after the experience modification. It can be seen that the flash temperature and contact temperature of a helical gear pair after the modification are significantly higher than those before the modification. However, too high temperature is easy to cause thermal deformation and scuffing failure of the helical gear.

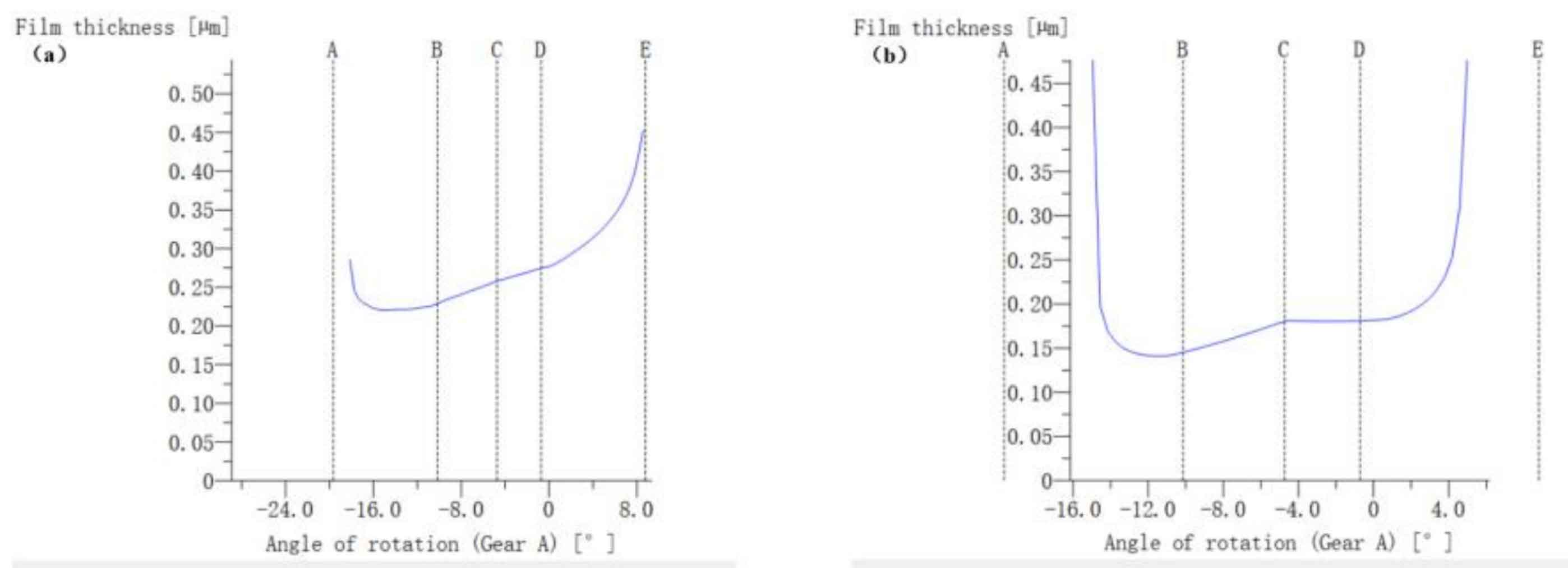

Figure 3 shows the oil film thickness curves of a helical gear pair before and after the experience modification. It can be seen that the oil film thickness of a helical gear pair after the modification has decreased as a whole compared with that before the modification, and the minimum value has decreased significantly, up to 0.06 μ m. This may cause insufficient oil lubrication during helical gear meshing, resulting in tooth surface wear and reduced service life.

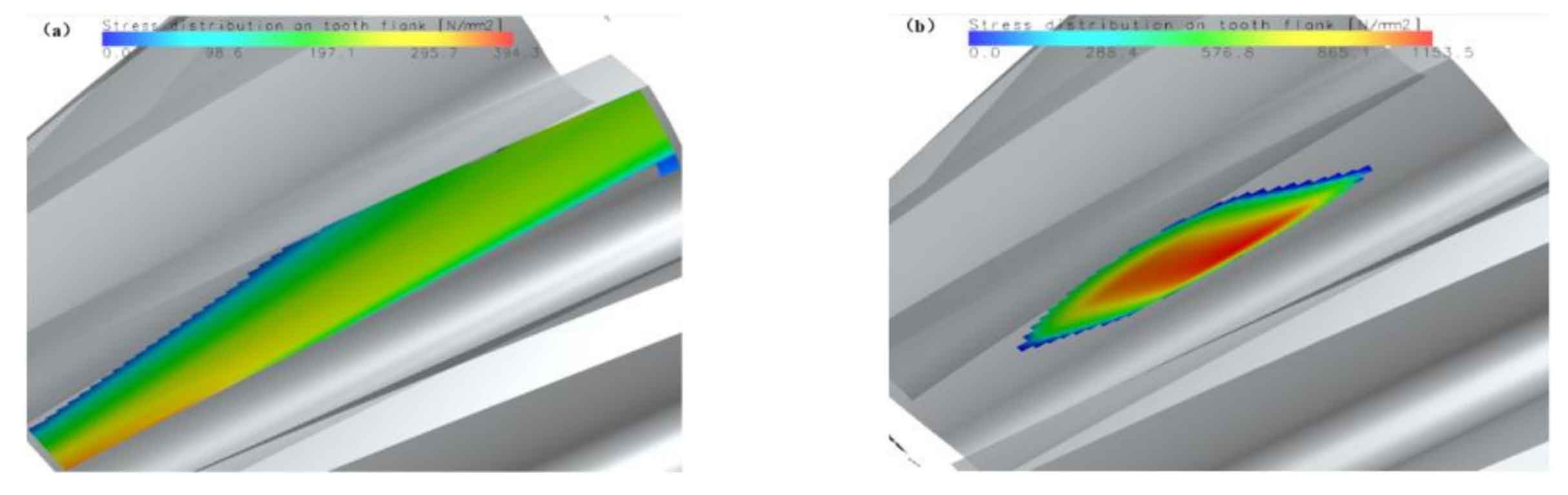

Figure 4 shows the contact spots on the tooth surface before and after the empirical modification of a helical gear pair. Although the load distribution on the tooth surface is improved and mainly concentrated in the middle of the gear teeth after the compound drum modification of the tooth profile and tooth direction, the maximum load actually increased by three times, which is easy to cause the tooth surface wear and even fracture, making the helical gear scrapped in advance.