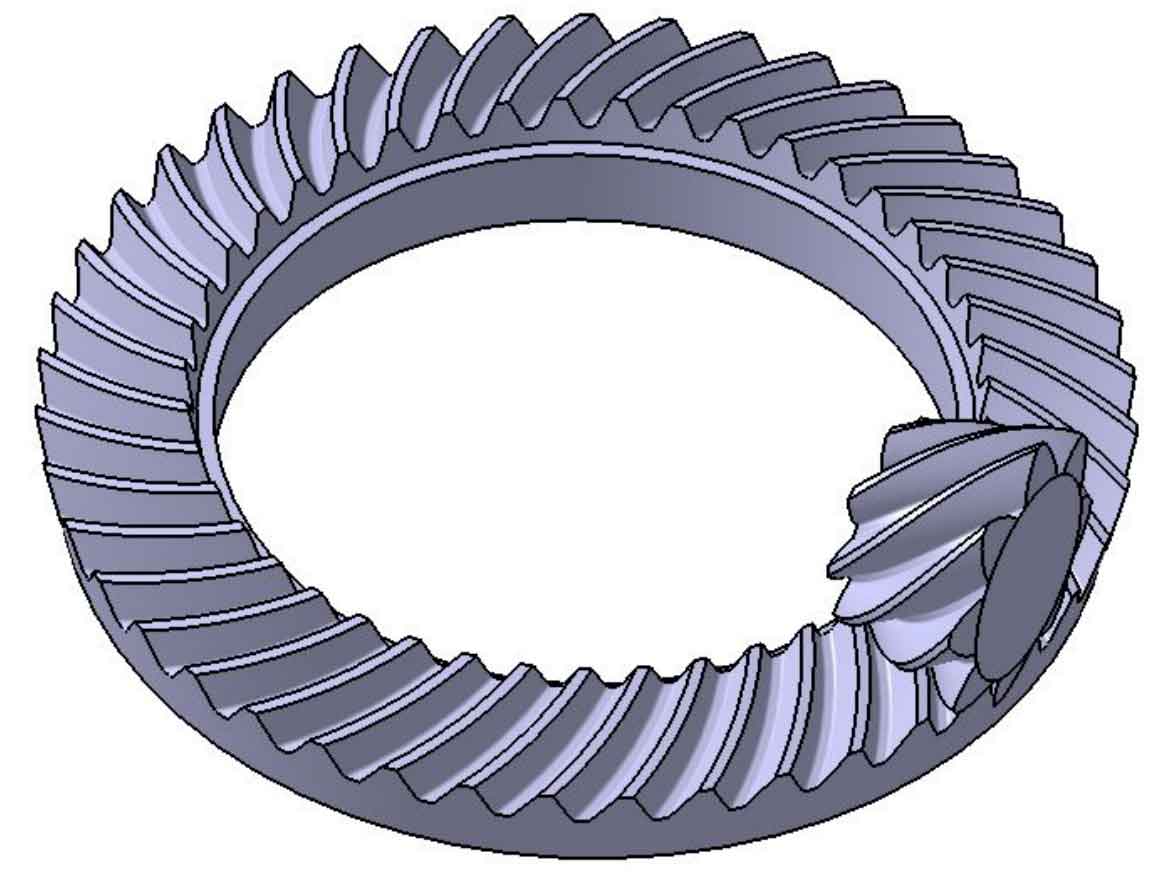

Taking the hypoid gear of the drive axle as the research object, the mechanism of fatigue and noise generation of the drive axle gear is deeply studied by means of simulation and experiment. From the perspective of the overall drive axle, the bending stress, bending fatigue life and noise radiation of the tooth root of the main reduction hypoid gear are analyzed, the fatigue life and noise prediction method of the drive axle gear is established, and the sensitivity of the bending strength and transmission error of the hypoid gear to the gear installation deviation is analyzed, forming a complete set of geometric modeling, bending strength, transmission error Analysis flow of meshing stiffness and noise radiation. It provides a basis for reliability design and noise optimization of drive axle gear.

- Aiming at the problem that it is difficult to obtain the tooth surface coordinates of the hypoid gear of the drive axle, according to the machining process of the hypoid gear, a method for solving the tooth surface coordinates of the hypoid gear based on numerical calculation is proposed. This method can automatically estimate the meshing midpoint of hypoid gears, and use this point as the initial point to calculate other coordinate points of the tooth surface.

- In order to accurately simulate the bending stress distribution of the hypoid gear tooth root of the drive axle, a prediction model of the bending stress of the hypoid gear based on the finite element method and considering the flexible deformation of the support shell is proposed. In order to speed up the calculation speed, the supporting structure such as the bridge shell in this model is replaced by the substructure model, which can not only ensure the calculation accuracy, but also improve the calculation speed.

- In view of the difficulty in calculating the time-varying meshing stiffness of the hypoid gear of the drive axle, this paper puts forward a complete calculation method for calculating the time-varying meshing stiffness of the hypoid gear based on the finite element method, and discusses in detail the establishment of the finite element model of the hypoid gear meshing and the calculation process of the meshing stiffness after analyzing the results. This method can be used to calculate the meshing stiffness of similar hypoid gears.