Gear forging technology continues to evolve, driven by the demand for higher performance, improved efficiency, and enhanced productivity. Several innovative developments are shaping the future of gear forging. Here are some key innovations in gear forging technology:

- Advanced Simulation and Modeling: The use of advanced simulation and modeling techniques is revolutionizing gear forging. Finite element analysis (FEA) and computer-aided design (CAD) tools allow for virtual prototyping and optimization of gear designs before physical production. These tools enable engineers to analyze material flow, stress distribution, and potential defects during the forging process, leading to improved gear quality and reduced development time.

- High-Speed Precision Forging: High-speed precision forging techniques are being developed to achieve faster production rates without compromising quality. By optimizing process parameters such as temperature, pressure, and deformation rates, high-speed precision forging enables the production of complex gears with high dimensional accuracy and tight tolerances. This technology enhances productivity and cost-effectiveness in gear manufacturing.

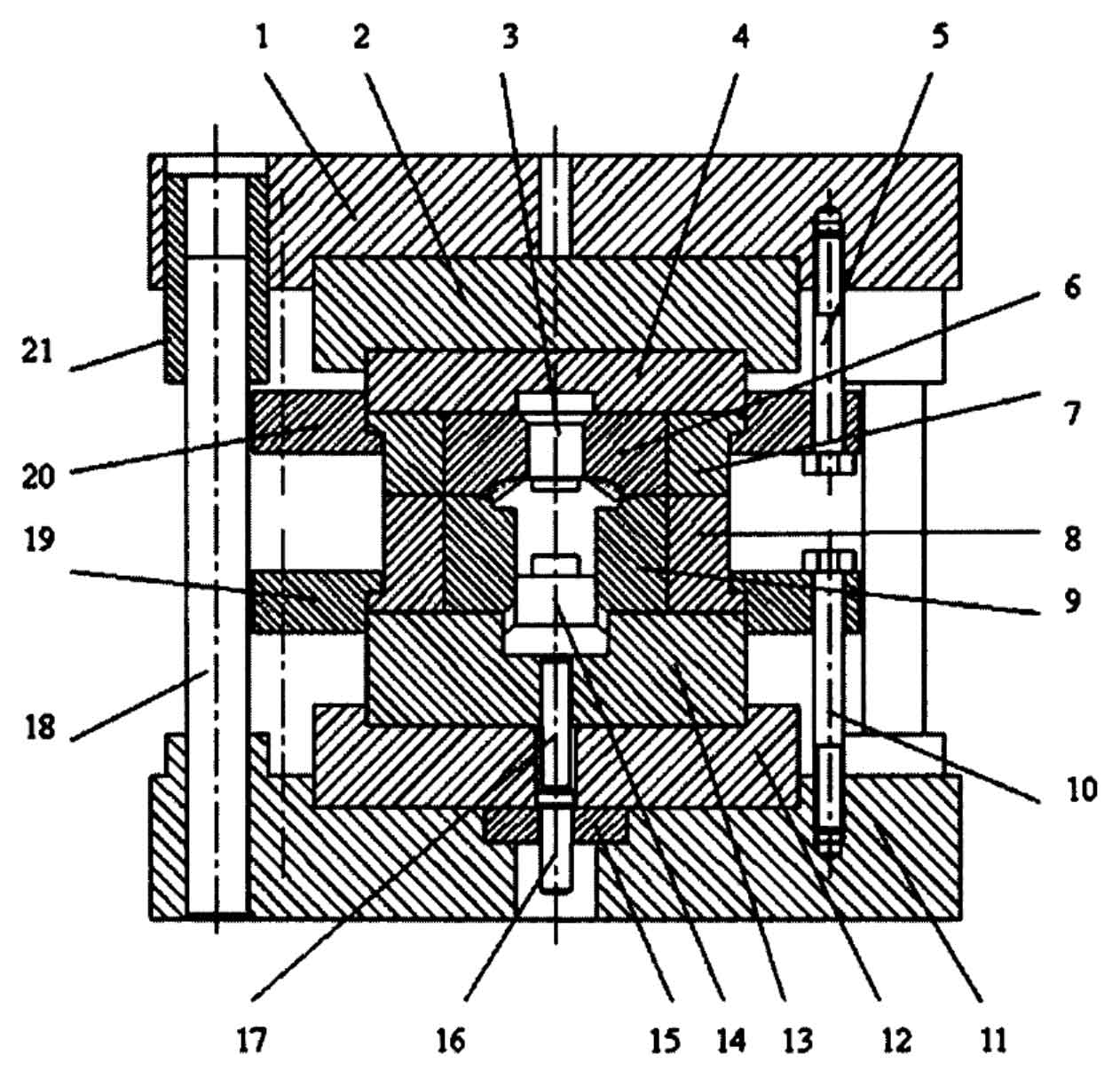

- Near-Net Shape Forging: Near-net shape forging aims to produce gears that require minimal post-forging machining. Advanced forging techniques, such as precision closed-die forging and warm forging, are employed to achieve gears with close-to-final shape and accurate tooth profiles. Near-net shape forging reduces material waste, machining costs, and lead times, resulting in more efficient and cost-effective production.

- Additive Manufacturing (3D Printing): Additive manufacturing, commonly known as 3D printing, is making significant strides in gear production. Metal additive manufacturing techniques, such as selective laser melting (SLM) and electron beam melting (EBM), enable the production of complex gear geometries with high precision. 3D printing allows for the creation of customized, lightweight, and optimized gear designs, offering new possibilities in aerospace, automotive, and other industries.

- Improved Material and Heat Treatment Technologies: Advancements in material science and heat treatment technologies are enhancing the properties and performance of forged gears. The development of advanced steel alloys, including micro-alloyed steels and advanced heat-treatable materials, provides gears with higher strength, improved wear resistance, and enhanced fatigue performance. Additionally, novel heat treatment techniques such as induction hardening and surface modification processes further optimize the material properties of forged gears.

- Smart Manufacturing and Industry 4.0 Integration: Gear forging is increasingly embracing smart manufacturing principles and Industry 4.0 technologies. Integration of sensors, real-time monitoring systems, and data analytics enables continuous process monitoring, quality control, and predictive maintenance. This integration enhances process efficiency, reduces downtime, and enables proactive decision-making in gear forging operations.

- Automation and Robotics: Automation and robotics are transforming gear forging operations by improving productivity, consistency, and safety. Robotic systems are employed for tasks such as loading and unloading forgings, die lubrication, and inspection. Automated forging cells and production lines streamline the manufacturing process, reduce labor costs, and enhance overall efficiency.

These innovations in gear forging technology are revolutionizing the industry, enabling the production of high-performance gears with improved precision, strength, and efficiency. Gear manufacturers are leveraging these advancements to meet the evolving demands of various industries, including automotive, aerospace, power generation, and heavy machinery. The future of gear forging holds exciting possibilities for further advancements, enabling even more sophisticated and efficient gear designs.