Interference analysis is one of the important contents of virtual assembly design of automobile rack and pinion steering gear. After the virtual assembly of automobile rack and pinion steering gear is completed, the assembly interference analysis of automobile rack and pinion steering gear components needs to be carried out, including collision and clearance calculation, constraint analysis, dependency analysis, update analysis, degree of freedom analysis, etc. Through interference analysis, we can know the intersection of automobile rack and pinion steering gear parts in assembly, the interference in assembly process, assembly relationship and assembly space. It can also adjust the assembly according to the assembly path and constraints until the ideal product is designed. In CATIA, there are generally five different results about assembly interference analysis: collision, contact plus collision, gap plus collision plus conflict, penetration depth, penetration depth versus specified penetration. For example, when two parts in the assembly design come into contact, it is necessary to analyze their collision interference. Generally, the assembly relationship between them is determined while opening the parts file of automobile rack and pinion steering gear, so as to reduce the collision calculation and improve the assembly speed.

Interference inspection is also a necessary link in the virtual assembly design of automobile rack and pinion steering gear. It is used to analyze whether the relationship between components is collision, contact or clearance.

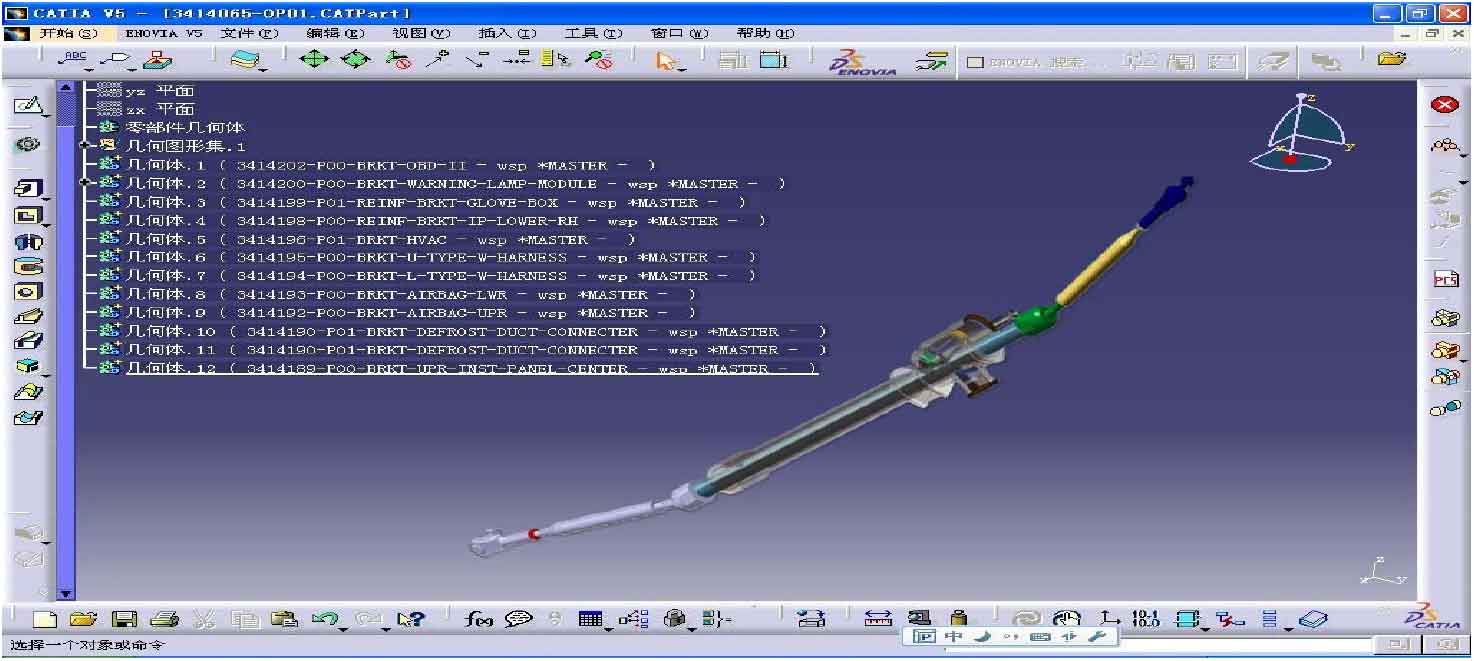

In the process of virtual assembly design of automobile rack and pinion steering gear, the interference analysis and inspection of the whole assembly of automobile rack and pinion steering gear are carried out, and it is found that there is interference between the gear and rack of automobile rack and pinion steering gear. Through the analysis of the inspection results, it is found that the main reason for the interference phenomenon is that the clearance between the gear and rack is too small when they are assembled. After modifying the design clearance, there is no interference during assembly, which shows that the assembly of automobile steering gear in this paper can be realized in actual production. After constraint and interference analysis and inspection of rack and pinion steering gear, the final rack and pinion steering gear is shown in the figure by adding rendering.