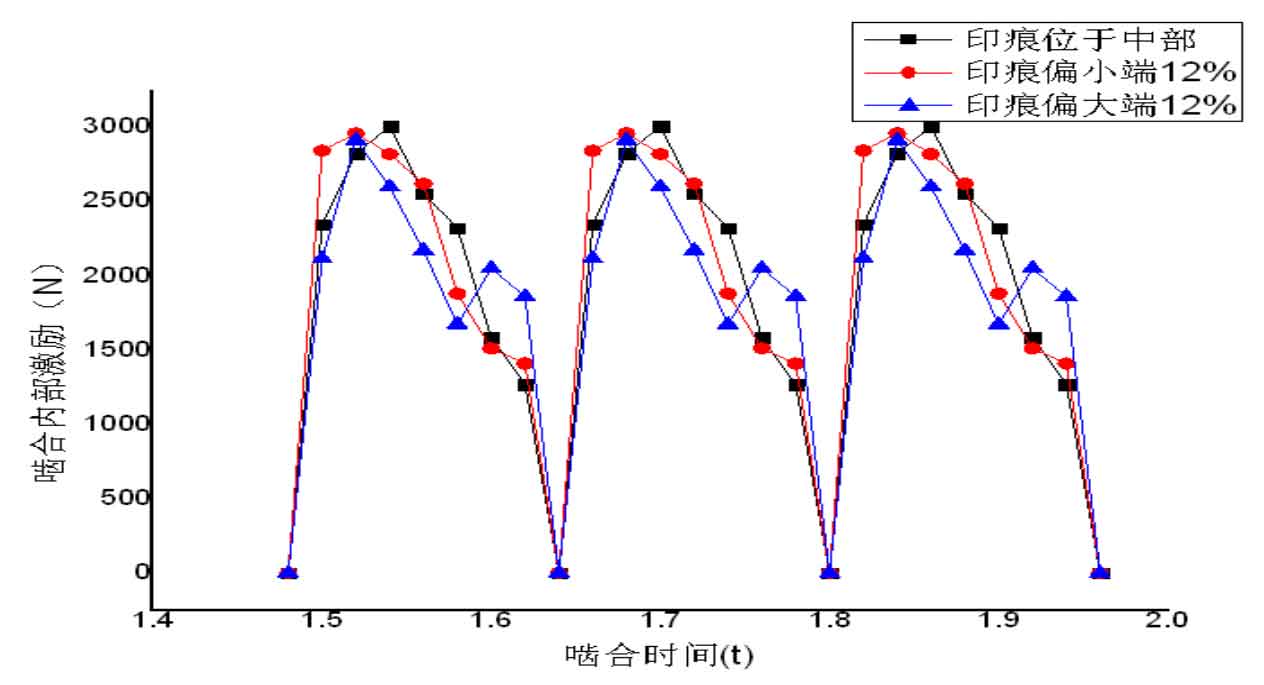

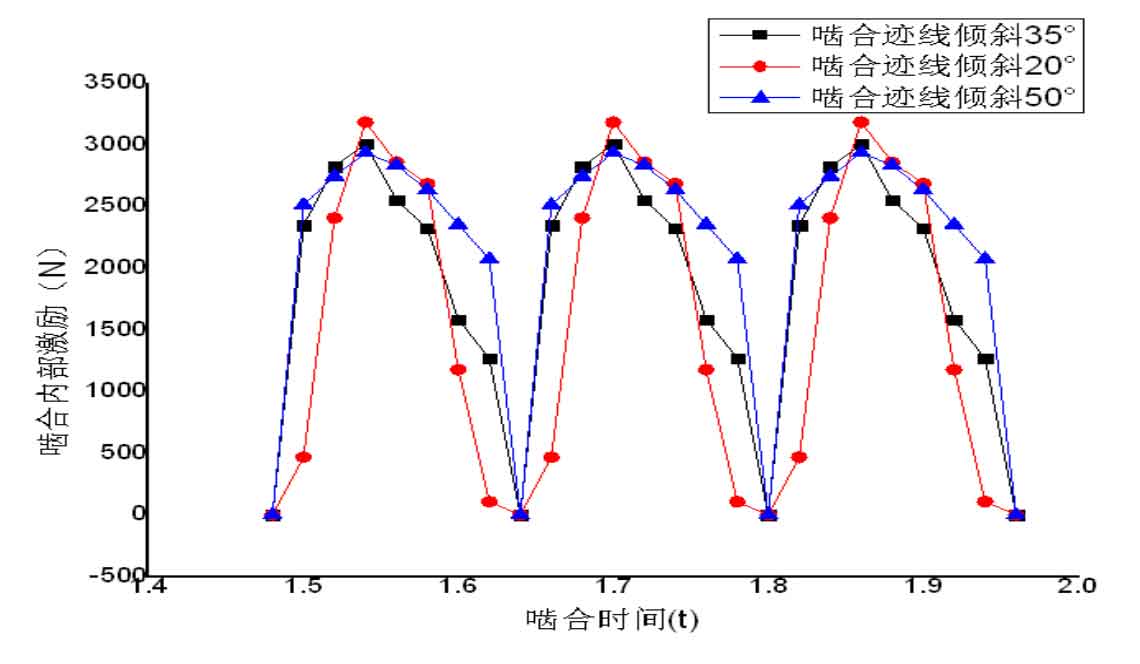

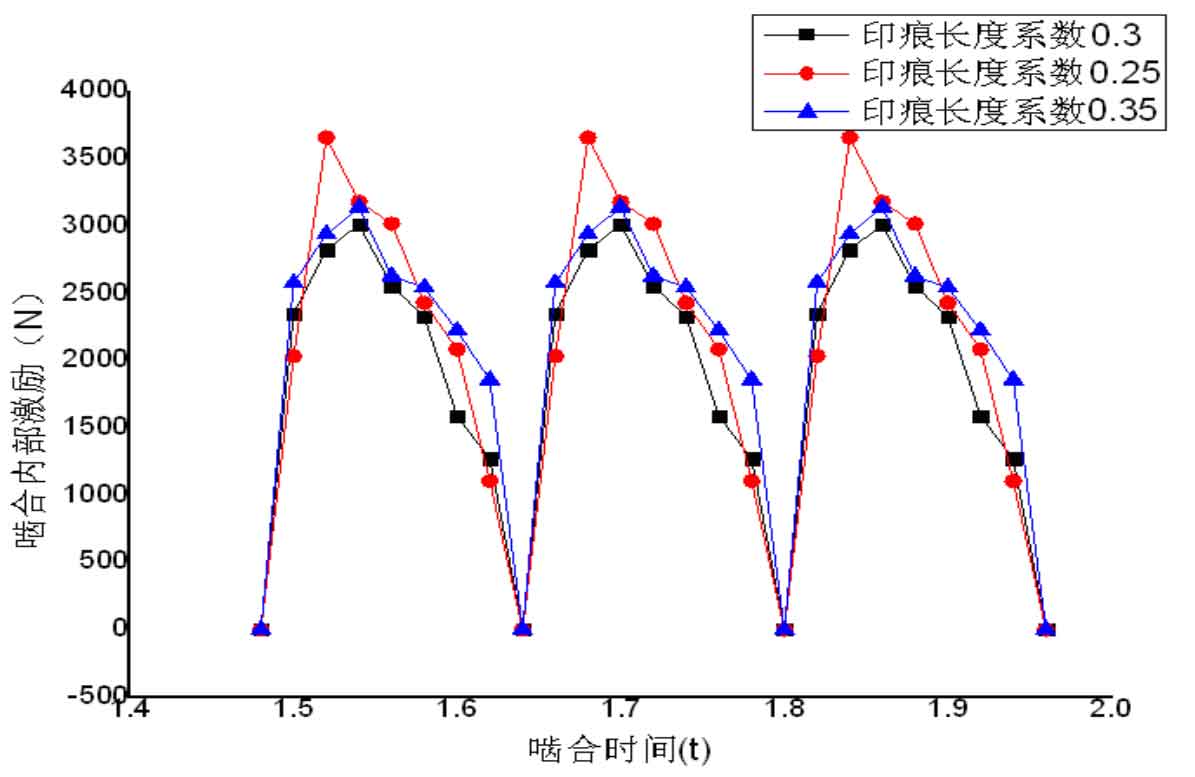

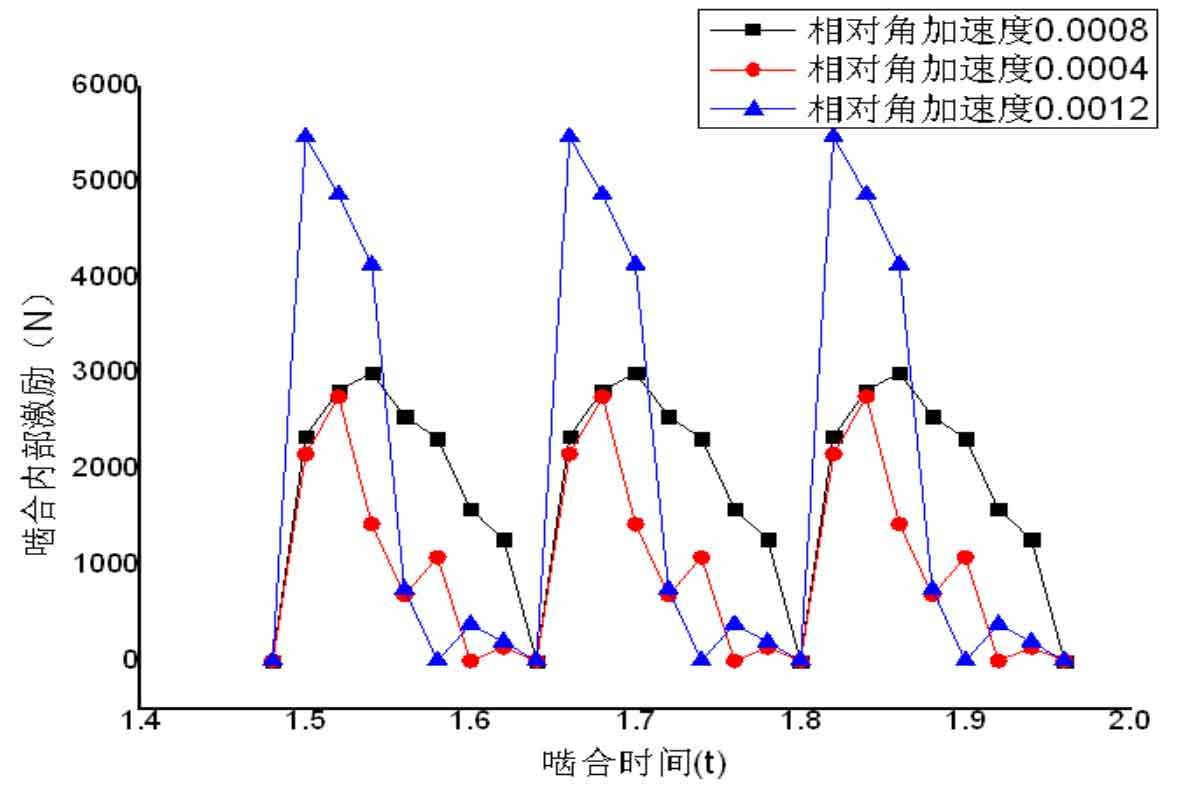

The meshing impression shape of the spiral bevel gear is an important index to measure its meshing quality, which will affect the internal excitation of meshing. In order to master the influence law of the meshing impression shape on the internal excitation of meshing. Still taking the 10×41 micro car rear axle hypoid gear pair as an example, using the above method, according to the impression position, the inclination of the meshing trace, the length of the impression and the relative angular acceleration of motion, three impression states are designed for each type, and the internal excitation of meshing is analyzed.

The impression shape parameters that are generally considered to have good transmission performance according to experience (the impression is located in the middle, the meshing trace is inclined by 35 °, the impression length coefficient is 0.3, and the relative angular velocity is 0.0008) are taken as the comparison benchmark. During calculation, the driving wheel applies a speed of 1000 rpm and the driven wheel applies a working torque of 820nm.

The comparison shows that: 1) the small offset of meshing mark position has no obvious effect on the internal excitation amplitude of spiral bevel gear; From the shape of the internal excitation curve, the curve with the meshing mark in the middle and slightly smaller end is smoother, and there is no obvious inflection point, which is more conducive to smooth transmission. 2) With the increase of the inclination of the meshing trace, the transition of the internal excitation curve of spiral bevel gear is more gentle, and the amplitude shows a downward trend. 3) The change of meshing mark length coefficient has little effect on the smoothness of internal excitation curve of spiral bevel gear. When the imprint length coefficient is 0.3, the internal excitation amplitude is the smallest, indicating that too long or too short imprint is not conducive to reducing the internal excitation of spiral bevel gear meshing. 4) As the relative angular velocity decreases, the internal excitation amplitude of spiral bevel gear also decreases, but when the relative angular velocity decreases to a certain amount, the internal excitation amplitude of spiral bevel gear does not decrease significantly, and the internal excitation curve also fluctuates. By comprehensive comparison, taking the middle value of relative angular velocity of motion as 0.0008 is more conducive to the smooth transmission of spiral bevel gear. To sum up, it is more conducive to the smooth transmission of spiral bevel gear that the appropriate amount of meshing mark is smaller, the inclination of meshing trace is increased, and the length coefficient of contact area and relative angular acceleration are taken as the middle value.