During gear hobbing, the gear hob axis and workpiece axis must conform to a certain axis intersection angle. However, when the gear hob is installed, there may be the intersection angle error of the gear hob installation shaft. Because the hobbing simulation model proposed in this paper is feasible and correct, it is the application of the proposed digital simulation method of cylindrical gear hobbing, and tests the influence of hob installation axis intersection angle error on tooth profile.

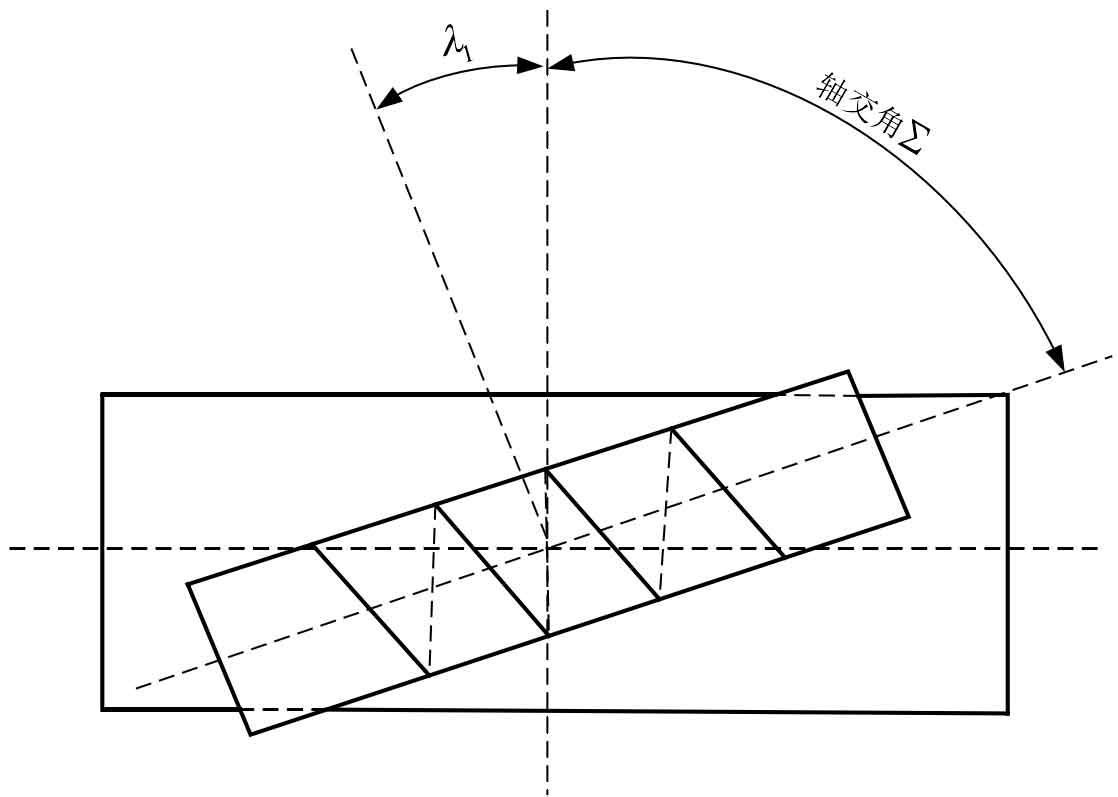

The intersection angle of hob installation axis refers to the minimum staggered angle between hob axis and gear axis, as shown in the figure. In the figure, ∑ represents the installation axis intersection angle of hob for hobbing spur gear, λ 1 indicates the spiral rise angle of hob. When hobbing cylindrical gear, the installation error of hob refers to the offset between the actual installation position and the theoretical installation position caused by various factors in the installation process of hob. The intersection angle error of hob installation axis refers to that the actual hob axis is inclined by an angle e Σ relative to the ideal hob axis.

If the deviation of hob installation shaft intersection angle is considered, at this time, it is only necessary to add the theoretical shaft intersection angle to the installation error E Σ of the formula hob and gear shaft intersection angle Σ.