Spiral bevel gear is mainly used in high-speed and heavy-duty staggered shaft transmission. The gear pair has compact structure and can realize large transmission ratio. In the high-speed transmission of gears with intersecting axes, the meshing of each pair of teeth of spur bevel gears is carried out simultaneously and rapidly. This meshing method is easy to produce impact, resulting in unstable transmission, high noise and poor bearing capacity. The spiral bevel gear gradually transits from one end of the tooth to the other end for continuous and stable meshing. In the spiral bevel gear transmission, at least two or more teeth mesh at the same time, and the overlap coefficient is large. Therefore, it has the advantages of low impact, stable transmission, low noise, strong bearing capacity and so on, The deficiency of straight bevel gear is well solved.

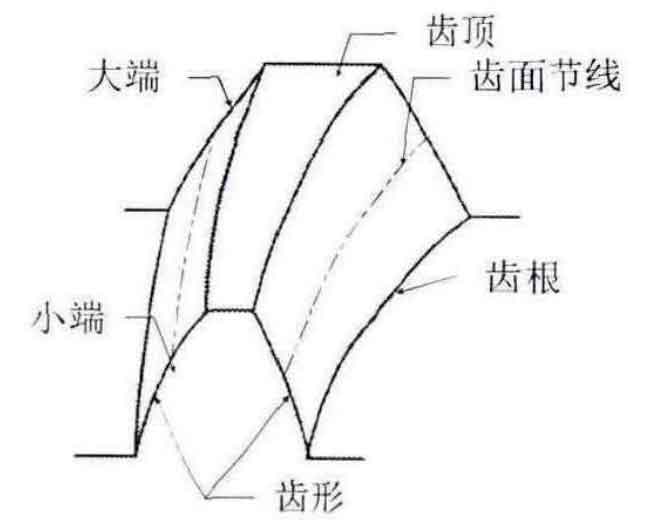

The elements on the tooth profile of spiral bevel gear and their names are shown in the figure. The pitch line refers to the intersection line between the tooth surface and the pitch cone surface. Any point on the pitch line is used as the tangent. The included angle between the tangent line and the pitch cone bus is the helix angle of this point. It is precisely due to the existence of helix angle that when the gear pair is meshed correctly, a large overlap coefficient can be obtained and the load specific pressure can be reduced, The tooth surface is worn evenly, the load capacity is enhanced, and the service life of the gear is prolonged.

According to different tooth systems, spiral bevel gears can be divided into Gleason tooth system, Oricon tooth system and Klinger tooth system, of which the first two are more commonly used. Spiral bevel gears can also be classified according to tooth height: along the direction of tooth length, according to whether the tooth height of big end and small end is consistent, spiral bevel gears can be divided into shrinkage teeth and equal height teeth. The tooth profile of the contraction tooth changes in proportion along the tooth length direction, and the tooth height of the equal height tooth remains unchanged along the tooth length direction. The spiral bevel gears made of Gleason teeth are mostly contraction teeth, and the spiral bevel gears made of Oricon teeth are usually equal height teeth.

The main basis for selecting the material of spiral bevel gear is the load to be borne by the gear, the accuracy of the gear, the speed and so on. According to the classification of load, it can be divided into light load, medium load, heavy load and overweight load. The manufacturing accuracy of gears has an important impact on the tooth profile accuracy, tolerance and meshing. Generally, the gear accuracy adopted by automobiles, medium and low-speed machine tools is grade 6-8, and the gear accuracy adopted by high-speed machine tools is grade 8-12. To measure the wear of gear tooth surface, the circumferential speed of gear is generally investigated. The gear is divided into low-speed gear (l-9m / s), medium-speed gear (6-10m / s) and high-speed gear (10-15m / s).

For gears with heavy load, medium and high speed and subject to large impact load, low alloy carburized steel or carbonitriding steel, such as 22CrMo, 20CrMnTi, 40Cr, etc., are generally selected. Carburizing, quenching and low temperature tempering processes are usually used for heat treatment, The surface hardness of the gear after heat treatment can reach 58-63hrc. Because the gear steel has good hardenability, the gear core material has high strength and toughness, and the wear resistance, fatigue strength and bending strength of the gear surface after heat treatment, The impact resistance of the heart was significantly improved. However, due to the large deformation caused by heat treatment, the gears with high accuracy generally need to be ground. During the working process, the driven spiral bevel gear of automobile rear axle is subjected to large force and frequent impact load, so it has high requirements for material properties. Practice shows that 22CrMo steel has excellent mechanical properties and machining properties, and is an ideal material for manufacturing the driven spiral bevel gear of automobile rear axle.