Distortion following carburizing and quenching is an inevitable and critical challenge in the manufacturing of automotive transmission components. As an engineer deeply involved in process optimization, I have observed that this distortion leads to a loss of precision, adversely affecting gear meshing, noise, and longevity. While precision grinding can compensate for predictable dimensional changes, its capacity is limited. When heat treatment distortion exceeds certain thresholds, it results in heat treatment defects that render the gear unscrapable or lead to non-uniform grinding, severely compromising its final performance and reliability. This article, based on my experimental work, delves into the root causes of abnormal post-quench distortion in thin-walled automotive gears and outlines effective preventive strategies.

The components under study are typical engine gears, such as camshaft and crankshaft gears, manufactured from material analogous to SAE 8620H (20CrMnTi). These gears are characterized by thin webs and lightening holes to reduce weight, which significantly compromises their structural rigidity. This inherent lack of stiffness makes them exceptionally prone to distortion, turning their heat treatment into a significant technical hurdle.

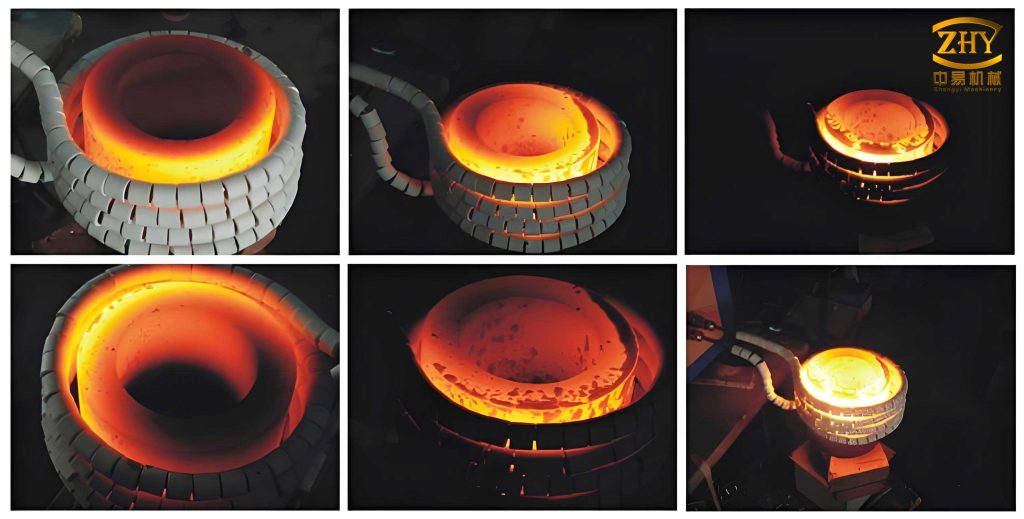

My experimental methodology focused on the factors with the most pronounced impact on distortion. The trials were conducted using a sealed quench furnace (model analogous to UNICASE) with an endothermic atmosphere generated from methanol and enriched with propane for carburizing. Carbon potential was controlled via an oxygen probe. Quenching was performed in a mar-tempering oil maintained at approximately 120°C. The key variables investigated were: fixturing method, fixture design, carburizing temperature, core hardness post-quench, and the protocol for re-quenching rejected parts.

Analysis of Distortion Mechanisms and Experimental Results

The distortion in gears is primarily a consequence of two major stresses generated during quenching: thermal stress and transformation stress. Thermal stress ($\sigma_{th}$) arises from steep temperature gradients and can be approximated by:

$$\sigma_{th} \propto E \cdot \alpha \cdot \Delta T$$

where $E$ is Young’s modulus, $\alpha$ is the coefficient of thermal expansion, and $\Delta T$ is the temperature differential between surface and core. Transformation stress ($\sigma_{tr}$) results from the volumetric expansion associated with the austenite-to-martensite transformation, which has a lower density. The total distortion-driving stress is a complex interplay: $\sigma_{total} = f(\sigma_{th}, \sigma_{tr})$. Abnormal distortion, a severe category of heat treatment defects, occurs when these stresses are exacerbated by process irregularities.

1. Influence of Loading Method

The method of stacking gears in the fixture—flat loading versus hanging—fundamentally alters cooling symmetry. For a camshaft gear, I measured flatness before and after treatment. Flat loading often leads to non-uniform cooling between the top and bottom faces, as the oil flow is impeded at the interface between gears. This, combined with the gear’s weight at elevated temperature where strength is low, promotes bending.

| Sample | Flat Loading | Hanging Loading | ||

|---|---|---|---|---|

| Pre-HT | Post-HT | Pre-HT | Post-HT | |

| 1 | 0.03 | 0.23 | 0.04 | 0.05 |

| 2 | 0.08 | 0.48 | 0.04 | 0.07 |

| 3 | 0.09 | 0.28 | 0.08 | 0.07 |

| 4 | 0.07 | 0.38 | 0.03 | 0.24 |

| 5 | 0.03 | 0.27 | 0.03 | 0.08 |

| Average | 0.06 | 0.33 | 0.04 | 0.10 |

The data clearly shows hanging loading produces significantly less and more consistent flatness deviation. The choice is gear-specific; symmetric thin gears benefit from hanging, while large-bore thin-walled gears may be better suited for flat loading with careful spacer design to ensure oil flow.

2. Critical Role of Fixture Design

A poorly designed fixture is a direct source of unpredictable heat treatment defects. I compared a generic vertical rod fixture (with 1.5 mm clearance to the gear bore) to a dedicated fixture with a much tighter clearance (0.4 mm). The large clearance allows gears to tilt and shift, leading to non-uniform bore cooling and erratic distortion.

| Sample | Generic Fixture | Dedicated Fixture | ||||

|---|---|---|---|---|---|---|

| Pre-HT Dia. | Post-HT Dia. | Δ | Pre-HT Dia. | Post-HT Dia. | Δ | |

| 1 | 54.08 | 54.21 | +0.13 | 54.08 | 54.11 | +0.03 |

| 2 | 54.09 | 54.26 | +0.17 | 54.07 | 54.12 | +0.05 |

| 3 | 54.08 | 54.31 | +0.23 | 54.09 | 54.19 | +0.10 |

| 4 | 54.09 | 54.21 | +0.12 | 54.08 | 54.18 | +0.10 |

| 5 | 54.08 | 54.34 | +0.26 | 54.08 | 54.15 | +0.07 |

| Average | 54.08 | 54.27 | +0.18 | 54.08 | 54.15 | +0.07 |

The dedicated fixture, by ensuring axial alignment and consistent bore exposure to quenchant, reduced average distortion by over 60%. This underscores the necessity of custom-designed fixtures for distortion-prone components to guarantee uniform heat extraction.

3. Impact of Excessive Carburizing Temperature

While increasing temperature accelerates carbon diffusion (governed by Fick’s law, with diffusivity $D \propto e^{-Q/RT}$), it severely reduces the yield strength of the material at high temperature. This makes the gear more susceptible to sagging and plastic deformation under its own weight or fixture load. An accidental furnace “over-temperature” event provided stark evidence. Gears carburized at an abnormally high temperature showed a dramatic shift in distortion magnitude.

| Distortion Range (mm) | 0.0 – 0.1 | 0.1 – 0.2 | 0.2 – 0.3 | > 0.3 |

|---|---|---|---|---|

| Number of Gears (n=20) | 2 | 5 | 8 | 5 |

This bimodal distribution, with many parts in the high-distortion bins, is characteristic of a process-related heat treatment defects event. The lesson is clear: temperature must be tightly controlled, often favoring the lower end of the typical 920-950°C range, and safeguards against furnace overshoot are mandatory.

4. The Core Hardness Conundrum

Core hardness, dictated by material hardenability and section size, directly influences transformation stress. Higher hardenability leads to a greater volume fraction of martensite in the core, increasing expansion. I tracked bore distortion and keyway width against core hardness for crankshaft gears.

| Measurement | Core Hardness (HRC) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 36 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | |

| Keyway Width | OK | OK | OK | OK | OK | OK | NG | NG | NG |

| Bore Δ (mm) | +0.03 | +0.09 | +0.08 | -0.06 | -0.07 | -0.10 | -0.17 | -0.23 | -0.26 |

The trend is unmistakable: as core hardness increases beyond approximately 40 HRC, bore distortion shifts from slight expansion to severe contraction, and keyways become undersized. This can be modeled by considering the volumetric strain from martensite, $ \epsilon_v \approx 0.04 \times f_m $, where $f_m$ is the martensite fraction. Controlling core hardness within a band, typically 35-42 HRC, is crucial to minimizing these volumetric heat treatment defects.

5. Managing the Risk of Re-Quenching

Re-quenching a previously hardened part is a high-risk operation that often amplifies distortion. The reason lies in the relief of residual stresses from the first quench during reheating, followed by a new, often more severe, stress cycle. However, intelligent re-processing can mitigate this. For a fuel pump gear prone to flatness issues, I compared re-quenching in the same orientation versus flipping the gear stack.

| Sample | Same Orientation | Flipped Orientation |

|---|---|---|

| 1 | 0.33 | 0.13 |

| 2 | 0.39 | 0.12 |

| 3 | 0.19 | 0.11 |

| 4 | 0.38 | 0.14 |

| 5 | 0.48 | 0.36 |

| Average | 0.35 | 0.17 |

Flipping the gear stack effectively causes the distortion from the second quench to act in opposition to the first, providing partial cancellation. This, combined with using the lowest possible re-austenitizing temperature, is a vital strategy for salvaging parts without inducing catastrophic heat treatment defects.

Integrated Preventive Strategy and Conclusion

Combating abnormal distortion requires a systemic approach targeting all identified factors. The preventive measures form a cohesive strategy:

- Loading & Fixturing: Select the loading method (flat/hanging) based on gear geometry to ensure symmetric cooling. Must-use: Dedicated, close-tolerance fixtures for critical components to enforce alignment and uniform quenching.

- Temperature Control: Implement robust furnace temperature control with redundant monitoring (e.g., dual thermocouples) to prevent overshoot. Choose carburizing temperature based on required case depth, favoring the lower end of the acceptable range to preserve high-temperature strength.

- Material & Cooling Control: Select steel grade hardenability in harmony with gear module and section size. The goal is a core hardness in the 35-42 HRC window. Utilize mar-tempering oils and consider internal support mandrels for bore-critical gears to manage cooling rates and minimize stress gradients.

- Re-processing Protocol: Establish a strict re-quenching procedure: mandatory re-orientation of gears (flipping) and the use of a reduced austenitizing temperature, just above Ac3, to minimize stress while achieving adequate microstructure.

In conclusion, abnormal distortion in automotive gears post carburizing and quenching is a multifaceted heat treatment defects problem rooted in process-induced stresses. It is not an act of fate but a controllable phenomenon. Through meticulous attention to fixture engineering, process parameter stability, core property management, and disciplined rework practices, these distortions can be predicted and minimized to within the compensation capacity of subsequent finishing operations. The journey from a distortion-prone process to a robust one is paved with data-driven analysis, as demonstrated by the experimental results herein, and a relentless focus on uniformity at every stage of the thermal cycle.