In practical applications, misalignments of the screw, rollers, and nut within a planetary roller screw assembly are inevitable due to manufacturing tolerances and assembly clearances. These misalignments critically influence key transmission performance metrics such as load distribution, efficiency, and operational lifetime. This article presents a comprehensive analytical methodology to determine the meshing position and the corresponding clearance for each pair of engaging thread teeth—between the screw and a roller, and between the nut and the same roller—when such misalignments are present.

The core of the analysis is the formulation of tangency conditions for the contacting helical surfaces under misaligned states, drawing upon the established theory of gearing. Mathematical models for the thread surfaces of the screw, roller, and nut are first developed. Coordinate transformation techniques are then employed to accurately describe the spatial deviations and angular tilts of each component from their nominal, perfectly aligned positions. Based on this framework, a set of governing equations is derived to solve for the unique meshing points and the associated clearances at both the screw-roller and nut-roller interfaces for every individual thread pair in a misaligned planetary roller screw assembly. The validity of the proposed model is confirmed by comparing its results for a perfectly aligned assembly with those from existing, well-established models, showing excellent agreement. Finally, the meshing properties at the screw-roller interface are analyzed in detail for a specific case of roller misalignment. The results demonstrate that misalignment causes significant deviations: the effective meshing radius varies from one thread tooth to another on the same component, the meshing deviation angles are no longer uniform, and crucially, multiple pairs of thread teeth cannot engage simultaneously, leading to a non-uniform load distribution. This investigation provides a fundamental analytical tool for predicting and optimizing the performance of a planetary roller screw assembly under real-world, non-ideal conditions.

Theoretical Foundation: Tangency Conditions Under Misalignment

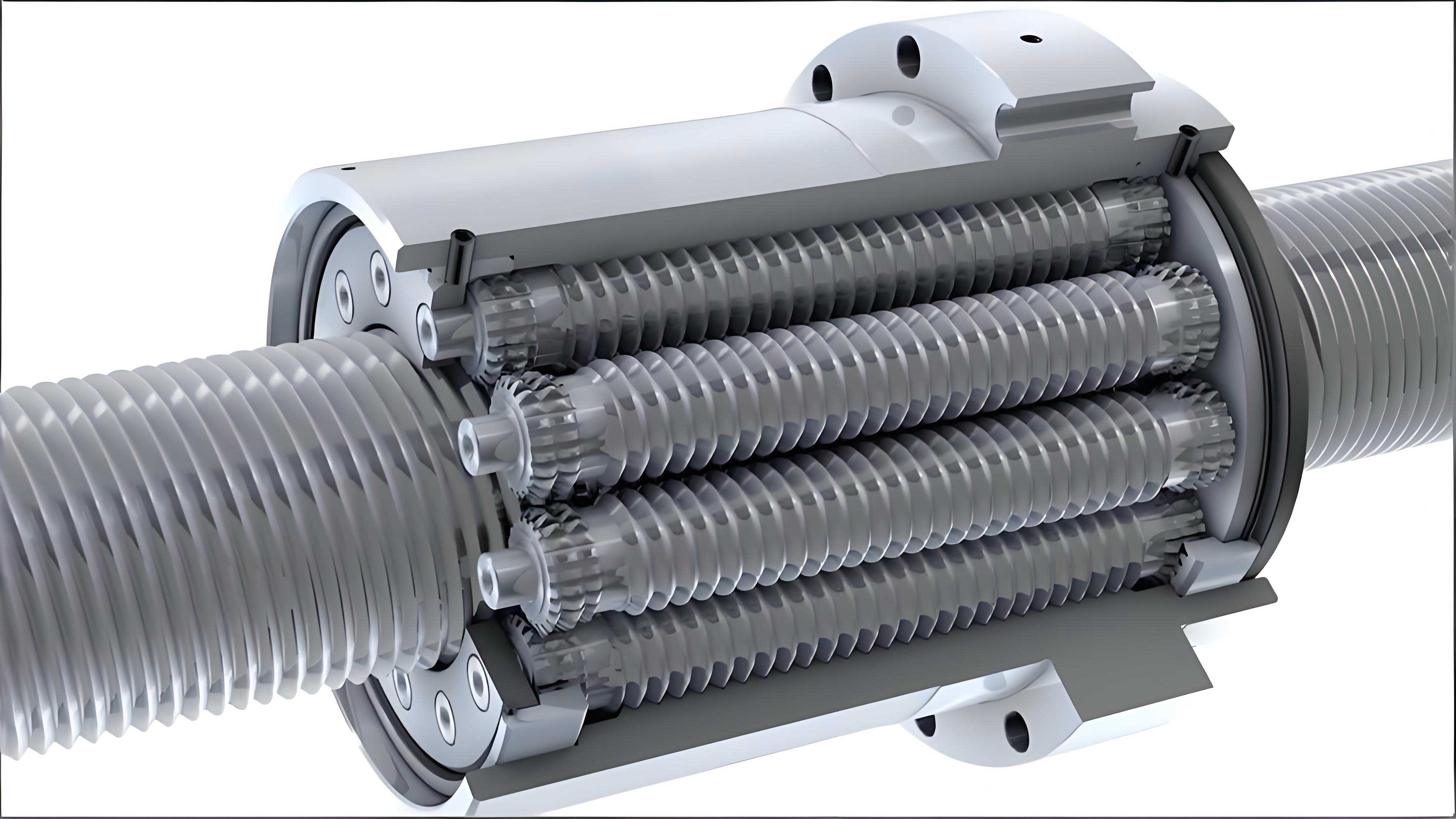

The planetary roller screw assembly operates by converting rotary motion into linear translation through the meshing of conjugate helical surfaces on the screw, multiple planetary rollers, and the nut. In an ideal, perfectly aligned state, the axes of all these components are parallel. However, in a practical planetary roller screw assembly, misalignments occur. Figure 1 illustrates a cross-sectional view of the screw and a roller, showing both the nominal (aligned) and misaligned states. Clearances, denoted as $\delta$, are inherently present between components to allow for assembly and motion.

For any pair of mating helical surfaces, such as a screw thread flank and a roller thread flank, continuous force transmission requires them to remain in tangential contact during operation. When misaligned, the nut or roller must translate along a spatial direction vector $\mathbf{e}$ (which may not be parallel to the screw axis) by a distance equal to the clearance $\delta$ to achieve contact. For two surfaces $\Sigma_l$ and $\Sigma_m$ to be in point contact at a location $M$, their position vectors and surface normal vectors must satisfy specific conditions at that point. The generalized tangency conditions for a misaligned planetary roller screw assembly are formulated as follows.

Let $\mathbf{r}_l(u_l, \theta_l)$ and $\mathbf{n}_l(u_l, \theta_l)$ be the position and unit normal vectors of surface $\Sigma_l$ in a fixed global coordinate system. Similarly, $\mathbf{r}_m(u_m, \theta_m)$ and $\mathbf{n}_m(u_m, \theta_m)$ are for surface $\Sigma_m$. The condition for tangency after compensating for the clearance is:

$$

\mathbf{r}_l(u_l, \theta_l) = \mathbf{r}_m(u_m, \theta_m) + \delta_{lm} \cdot \mathbf{e}_{lm}

$$

$$

\mathbf{n}_l(u_l, \theta_l) = \zeta \cdot \mathbf{n}_m(u_m, \theta_m)

$$

Here, $\delta_{lm}$ is the clearance between the two surfaces, $\mathbf{e}_{lm}$ is the unit vector along the direction of relative approach to close the clearance, and $\zeta$ is a scalar constant. These two vector equations yield five independent scalar equations that can be solved for the five unknowns: the two surface parameters for each surface ($u_l$, $\theta_l$, $u_m$, $\theta_m$) and the clearance $\delta_{lm}$. This system defines the unique meshing point $M$ for that specific tooth pair in the misaligned planetary roller screw assembly.

Mathematical Modeling of Thread Surfaces

To apply the tangency conditions, precise mathematical descriptions of the thread surfaces are essential. Separate coordinate systems are fixed to the screw ($o_Sx_Sy_Sz_S$), the roller ($o_Rx_Ry_Rz_R$), and the nut ($o_Nx_Ny_Nz_N$), with their $z$-axes coincident with the component’s nominal axis. The thread profile for the screw and nut is typically trapezoidal (or modified trapezoidal), while the roller profile is often circular (gothic arc) to accommodate misalignment and provide a favorable contact ellipse.

The surface of a thread can be generated by sweeping its profile along a helical path. For a screw with a straight flank profile, the position vector of a point on its $j$-th thread in its local coordinate system can be expressed as:

$$

\mathbf{r}^S_{S,j}(u_S, \theta_S) = \begin{bmatrix}

(r_{S0} + u_S) \cos(\theta_S + \theta_{S0,j}) \\

(r_{S0} + u_S) \sin(\theta_S + \theta_{S0,j}) \\

\mp (c_S – u_S \tan\beta_{S0}) + \frac{L_S}{2\pi}\theta_S

\end{bmatrix}

$$

where $r_{S0}$ is the nominal screw radius, $u_S$ is the profile parameter, $\theta_S$ is the angular parameter, $\theta_{S0,j}$ is the starting angle of the $j$-th thread, $c_S$ is the half-thickness, $\beta_{S0}$ is the flank angle, $L_S$ is the lead, and the $\mp$ sign corresponds to the upper ($\Sigma_1$) and lower ($\Sigma_2$) flanks, respectively.

For a roller with a circular profile of radius $r_{PR}$, the surface equation is more complex:

$$

\mathbf{r}^R_{R}(u_R, \theta_R) = \begin{bmatrix}

(r_{R0} + u_R) \cos(\theta_R + \theta_{R0}) \\

(r_{R0} + u_R) \sin(\theta_R + \theta_{R0}) \\

\pm \sqrt{ r_{PR}^2 – (u_R – u_{PR})^2 } + w_{PR} + \frac{L_R}{2\pi}\theta_R

\end{bmatrix}

$$

Here, $u_{PR}$ and $w_{PR}$ define the center of the circular arc relative to the roller’s nominal profile. The nut’s thread surface has a form similar to the screw’s but with appropriate sign changes and its own nominal radius $r_{N0}$ and parameters.

Modeling Misalignments via Coordinate Transformations

The misalignment of any component in the planetary roller screw assembly is modeled using coordinate transformations from its local system to the fixed global system. A component’s pose is defined by a translation vector $\mathbf{p}_i$ (representing offset from its nominal position) and a rotation matrix $\mathbf{H}_i$ (representing tilt). The rotation matrix is commonly defined by two tilt angles, $\psi_i$ and $\varphi_i$, representing rotations about axes perpendicular to the global $z$-axis.

$$

\mathbf{H}_i(\psi_i, \varphi_i) = \begin{bmatrix}

\cos\psi_i & \sin\psi_i \sin\varphi_i & \sin\psi_i \cos\varphi_i \\

0 & \cos\varphi_i & -\sin\varphi_i \\

-\sin\psi_i & \cos\psi_i \sin\varphi_i & \cos\psi_i \cos\varphi_i

\end{bmatrix}

$$

Thus, a point on a component’s surface in the global system is given by:

$$

\mathbf{r}_i^{\text{global}} = \mathbf{H}_i \cdot \mathbf{r}^i_{\text{local}} + \mathbf{p}_i

$$

This transformation is applied to the surface equations of the screw, roller, and nut. A specific and common misalignment scenario is the rotation of a component (like a roller) about a pivot point $\mathbf{p}_{ir}$ that is not its own origin, such as a gimbal point within a retainer. In this case, the global position $\mathbf{p}_i$ becomes:

$$

\mathbf{p}_i = \mathbf{H}_i \cdot (\mathbf{p}_{i0} – \mathbf{p}_{ir}) + \mathbf{p}_{ir}

$$

where $\mathbf{p}_{i0}$ is the nominal position. This accurately captures the kinematic effect of tilt in a real planetary roller screw assembly.

Derivation of Meshing Equations for a Misaligned Assembly

Applying the tangency conditions to the transformed surfaces yields the governing meshing equations. We consider the interface between the screw (tooth $k_S$) and the roller (tooth $k_{Rs}$ on the screw side). The meshing point on each is defined by its meshing radius ($r_{Sc}^{k_S}$, $r_{Rsc}^{k_{Rs}}$) and meshing deviation angle ($\phi_{Sc}^{k_S}$, $\phi_{Rsc}^{k_{Rs}}$), measured from the component’s $x$-axis in its own coordinate plane.

For the screw’s upper flank ($\Sigma_{S1}$) contacting the roller’s lower flank ($\Sigma_{R2}$), the tangency conditions lead to the following system of equations:

$$

\mathbf{H}_S \cdot \mathbf{r}^{S}_{Sc}(r_{Sc}^{k_S}, \phi_{Sc}^{k_S}) + \mathbf{p}_S = \mathbf{H}_R \cdot \mathbf{r}^{R}_{Rsc}(r_{Rsc}^{k_{Rs}}, \phi_{Rsc}^{k_{Rs}}) + \mathbf{p}_R + \delta_{SR}^{k_{Rs}} \cdot \mathbf{e}_{SR}

$$

$$

\mathbf{H}_S \cdot \mathbf{n}^{S}_{Sc}(r_{Sc}^{k_S}, \phi_{Sc}^{k_S}) = \zeta \cdot \mathbf{H}_R \cdot \mathbf{n}^{R}_{Rsc}(r_{Rsc}^{k_{Rs}}, \phi_{Rsc}^{k_{Rs}})

$$

Here, $\mathbf{r}^{S}_{Sc}$ and $\mathbf{n}^{S}_{Sc}$ are the position and normal vectors of the screw tooth defined in terms of its meshing radius and angle. They incorporate the screw’s geometry and lead:

$$

\mathbf{r}^{S}_{Sc} = \begin{bmatrix}

r_{Sc}^{k_S} \cos\phi_{Sc}^{k_S} \\

r_{Sc}^{k_S} \sin\phi_{Sc}^{k_S} \\

\frac{L_S}{2\pi} \left( \phi_{Sc}^{k_S} + 2\pi\frac{k_S-1}{n_S} \right) – (c_S – (r_{Sc}^{k_S}-r_{S0})\tan\beta_{S0})

\end{bmatrix}

$$

The normal vector $\mathbf{n}^{S}_{Sc}$ depends on the local lead angle $\lambda_{Sc}^{k_S} = \arctan(L_S / (2\pi r_{Sc}^{k_S}))$. The expressions for the roller’s surface and normal vector $\mathbf{r}^{R}_{Rsc}$, $\mathbf{n}^{R}_{Rsc}$ are more complex due to the circular profile, involving terms like $\sqrt{r_{PR}^2 – (r_{Rsc}^{k_{Rs}}-r_{R0} – u_{PR})^2}$ and its derivative for the local flank angle $\beta_{Rsc}^{k_{Rs}}$.

For a given misalignment defined by $\mathbf{H}_S$, $\mathbf{p}_S$, $\mathbf{H}_R$, $\mathbf{p}_R$, and approach direction $\mathbf{e}_{SR}$ (often $(0,0,\mp1)^T$), and for a specific tooth pair index $k_S = k_{Rs}$, this system can be solved numerically. By iterating $k_{Rs}$ from 1 to the total number of engaged teeth $n_T$, one obtains the meshing parameters and clearance $\delta_{SR}^{k_{Rs}}$ for every single screw-roller tooth pair in the planetary roller screw assembly.

An identical process is applied to the nut-roller interface, solving for the meshing of nut tooth $k_N$ with roller tooth $k_{Rn}$ on the nut side. The governing equations are:

$$

\mathbf{H}_N \cdot \mathbf{r}^{N}_{Nc}(r_{Nc}^{k_N}, \phi_{Nc}^{k_N}) + \mathbf{p}_N = \mathbf{H}_R \cdot \mathbf{r}^{R}_{Rnc}(r_{Rnc}^{k_{Rn}}, \phi_{Rnc}^{k_{Rn}}) + \mathbf{p}_R + \delta_{NR}^{k_{Rn}} \cdot \mathbf{e}_{NR}

$$

$$

\mathbf{H}_N \cdot \mathbf{n}^{N}_{Nc}(r_{Nc}^{k_N}, \phi_{Nc}^{k_N}) = \zeta \cdot \mathbf{H}_R \cdot \mathbf{n}^{R}_{Rnc}(r_{Rnc}^{k_{Rn}}, \phi_{Rnc}^{k_{Rn}})

$$

Where the relationship between tooth indices depends on the engaging flanks (e.g., $k_N = k_{Rn}+1$ for nut $\Sigma_{N2}$ contacting roller $\Sigma_{R1}$). Solving for all $k_{Rn}$ gives the complete meshing picture at the nut side of the planetary roller screw assembly.

Validation and Case Study Analysis

The proposed model is first validated against established results for a perfectly aligned planetary roller screw assembly. Using the parameters listed in Table 1, the calculated meshing positions from the new model match closely with those from prior literature, as shown in Table 2. The model also provides the axial clearance, a value not typically computed by simpler alignment models.

| Parameter | Screw | Roller | Nut |

|---|---|---|---|

| Nominal Radius $r_0$ (mm) | 9.75 | 3.25 | 16.25 |

| Tooth Crest Height $a$ (mm) | 0.22 | 0.22 | 0.22 |

| Tooth Root Height $b$ (mm) | 0.265 | 0.265 | 0.265 |

| Half-Thickness $c$ (mm) | 0.282 | 0.310 | 0.310 |

| Flank Angle $\beta_0$ (°) | 45 | 45 | 45 |

| Number of Starts $n$ | 5 | 1 | 5 |

| Pitch $P$ (mm) | 1.2 | 1.2 | 1.2 |

| Roller Profile Radius $r_{PR}$ (mm) | — | 4.597 | — |

| Number of Engaged Teeth on Roller (Screw side) $n_T$ | — | 25 | — |

| Meshing Parameter | Prior Model | Proposed Model |

|---|---|---|

| Screw Meshing Radius $r_{Sc}$ (mm) | 9.775 | 9.775 |

| Screw Meshing Angle $\phi_{Sc}$ (°) | 2.232 | 2.227 |

| Roller Meshing Radius $r_{Rsc}$ (mm) | 3.255 | 3.255 |

| Roller Meshing Angle $\phi_{Rsc}$ (°) | 6.715 | 6.701 |

| Screw-Roller Axial Clearance $\delta_{SR}$ (mm) | — | 0.0123 |

We now analyze a specific misalignment case: the screw remains aligned, but a roller tilts by an angle $\varphi_R = 3$ arcminutes about a pivot point located at the axial center of its engaged length with the screw $\left( \mathbf{p}_{Rr} = (0, 0, (P n_T)/2)^T \right)$. The direction vector $\mathbf{e}_{SR}$ is assumed to remain parallel to the screw’s axis.

The results reveal profound changes in the meshing behavior of the planetary roller screw assembly. First, the meshing point on each individual thread tooth of the roller shifts. As shown conceptually in the analysis, the meshing radius $r_{Rsc}^{k_{Rs}}$ is no longer constant but varies along the roller’s length. Similarly, the meshing deviation angle $\phi_{Rsc}^{k_{Rs}}$ differs for each tooth. The symmetric engagement about the roller’s $x_R$-$z_R$ plane is lost. The same non-uniformity applies to the corresponding meshing points on the screw threads.

Secondly, the overall axial clearance $\delta_{SR}$ for the entire interface changes. For a tilt of $+3’$, it increases slightly to 0.013 mm. A tilt in the opposite direction would decrease it.

Most significantly, the analysis of individual tooth-pair clearances $\delta_{SR}^{k_{Rs}}$ reveals that not all teeth can share the load simultaneously. When considering either possible driving flank contact (screw $\Sigma_{S1}$/roller $\Sigma_{R2}$ or screw $\Sigma_{S2}$/roller $\Sigma_{R1}$), the calculated clearance is different for each engaged tooth pair. Only the tooth pair with the smallest positive clearance (or largest negative interference, requiring elastic deformation) will actually carry load in a static or quasi-static scenario. This is summarized by the effective assembly clearance being the minimum sum across all potential contact paths:

$$

\delta_{SR} = \min\left[ (\delta_{SR1}^{1} + \delta_{SR2}^{1}), (\delta_{SR1}^{2} + \delta_{SR2}^{2}), \dots \right]

$$

This non-simultaneous contact drastically alters the load distribution from the ideal, uniformly loaded state, potentially leading to premature wear and reduced fatigue life in the highly loaded tooth of the planetary roller screw assembly.

Conclusion

This investigation has developed a rigorous analytical methodology for determining the meshing characteristics of a planetary roller screw assembly operating under realistic conditions of component misalignment. The core achievement is the derivation of a set of equations capable of calculating the precise meshing position and the associated clearance for every single pair of engaging thread teeth at both the screw-roller and nut-roller interfaces.

The key findings for a misaligned planetary roller screw assembly are:

- Non-Uniform Meshing Geometry: The meshing radius and meshing deviation angle become variable along the length of the engaged threads on both the screw and the roller, breaking the symmetry present in the aligned state.

- Loss of Simultaneous Contact: Multiple pairs of thread teeth cannot mesh simultaneously. The clearance varies significantly from one tooth pair to another, meaning that under load, only a subset of teeth (often just one or two) will actually be in contact and transmit force at any given instant.

- Altered System Clearance: The overall axial clearance of the interface is sensitive to the type and magnitude of misalignment, increasing or decreasing from its nominal aligned value.

These findings have direct and critical implications for the performance prediction of a planetary roller screw assembly. The non-uniform load distribution resulting from misalignment directly affects static and dynamic stiffness, fatigue life of components, positioning accuracy, and frictional losses. The model presented here serves as an essential foundation for advanced studies into load distribution analysis, efficiency calculation, stiffness modeling, and reliability assessment of the planetary roller screw assembly under real-world operating conditions, enabling more robust and optimized design.