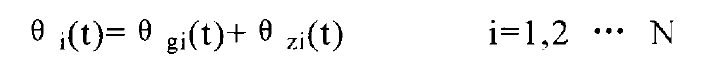

In the process of gear transmission, the rotation angle of each tooth of the driven gear can be expressed as:

Where:

θgI (t) – rigid angle of gear teeth;

θzi (t) – lag angle;

i. N – serial number of teeth participating in meshing and number of teeth participating in meshing

When the gear is driven as a whole, the rigid angle of each point on the tooth surface of the gear is equal, that is:

Under load, the transmission error of gear pair can be divided into two parts: one is the tooth surface mismatch error along the contact trace, and the other is the transmission error caused by the elastic deformation of gear teeth. In addition, we also take heat treatment deformation and other errors into account, so the comprehensive transmission error, i.e. lag angle, is:

Where:

θm(T) – lag angle caused by tooth surface mismatch error;

θ1(T) – lag angle caused by elastic deformation of gear teeth;

θr(T) – lag angle caused by other errors;

From the perspective of deformation, in order to realize coordinated transmission of gear pairs engaged at the same time, the lag angle caused by transmission error of gear pairs engaged at the same time should be equal, that is:

The rotation angle of each meshing tooth shall also be equal, that is:

The formula is called “coordination principle of transmission angular displacement of simultaneous meshing gear pairs”, which is an important law of Gear Loading meshing.