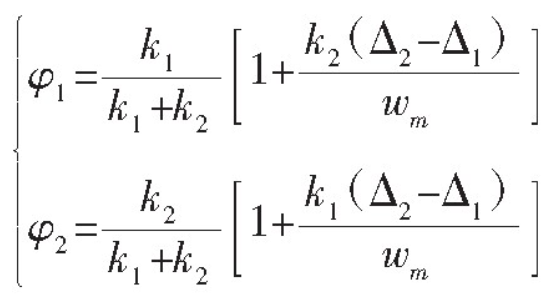

For the gears whose coincidence degree is between (1 ~ 2), the meshing process is always in the alternating meshing of single and double teeth. In the single tooth meshing area, only one pair of teeth participate in the meshing, and the load transmitted by the wheel pair is borne by all the teeth, so there is no problem of load distribution. In the double tooth meshing area, the load is shared by two pairs of teeth. The problem of load distribution between teeth can be equivalent to that of two springs in parallel at the same time, because the meshing stiffness of the teeth is time-varying Therefore, the load distribution coefficient is also time-varying. The load distribution proportion formula is as follows:

The criteria for judging the engagement of single and double teeth after reshaping are as follows:

In the formula, the load distribution ratio of gear pair 1 and gear pair 2 in φ 1 and φ 2-double tooth meshing area participating in meshing at the same time; the comprehensive meshing stiffness of K1, k2-meshing gear pair 1 and meshing gear pair 2; the modification amount of △ 1, △ 2-gear pair 1 and gear pair 2; the average unit line load in WM direction of gear width.

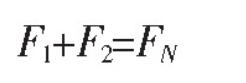

According to Newton’s third law force and reaction force, the same meshing pair of driving and driven gears bear the same load. Since the gear torque is constant when the power and speed are determined, the total load remains unchanged, and the two tooth pairs meshed at the same time in the double tooth meshing area also meet the force coordination equation: