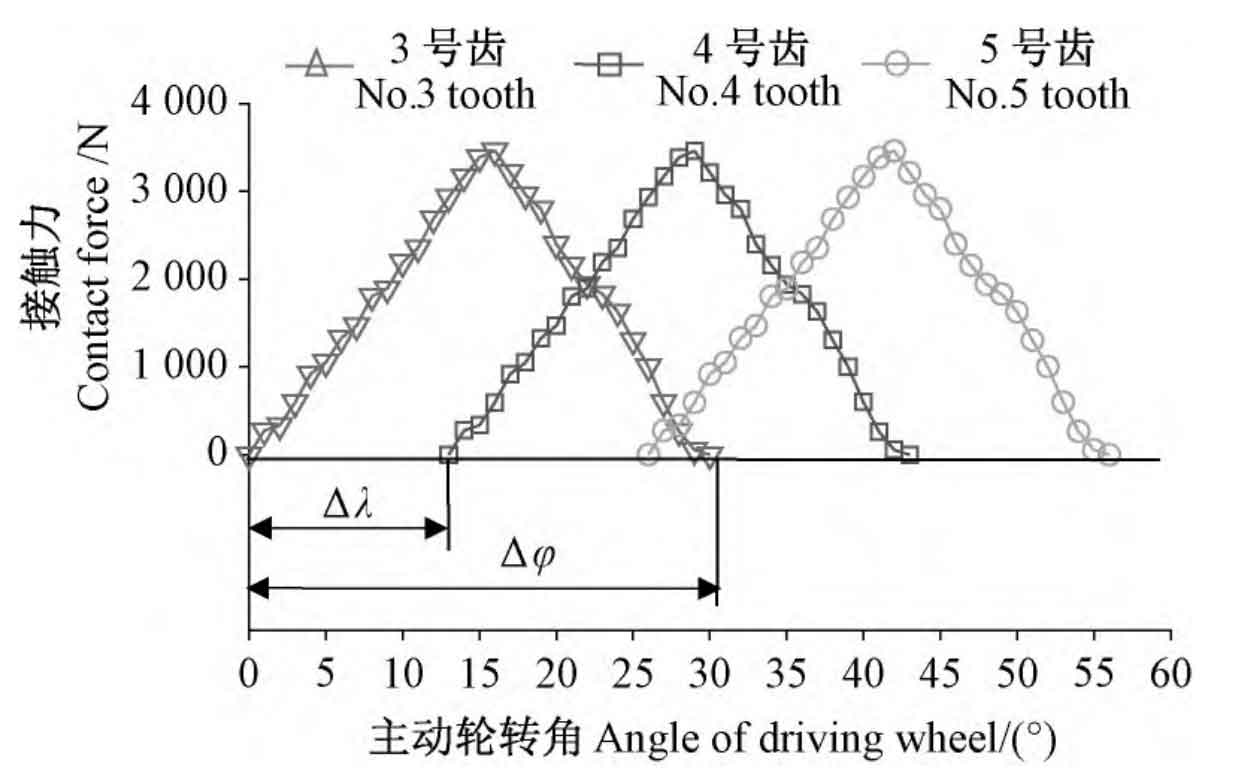

Under the actual working condition, the double-arc spiral bevel gear pair is in the state of multi-tooth meshing alternately. In order to clarify the load distribution between gear teeth, this paper uses the load distribution coefficient to characterize. Load distribution coefficient refers to the ratio of the contact force Fj borne by a single tooth to the total contact force of all meshing teeth at the same time during the meshing process of double-arc spiral bevel gears, namely:

Where, n is the number of all meshing teeth at a time.

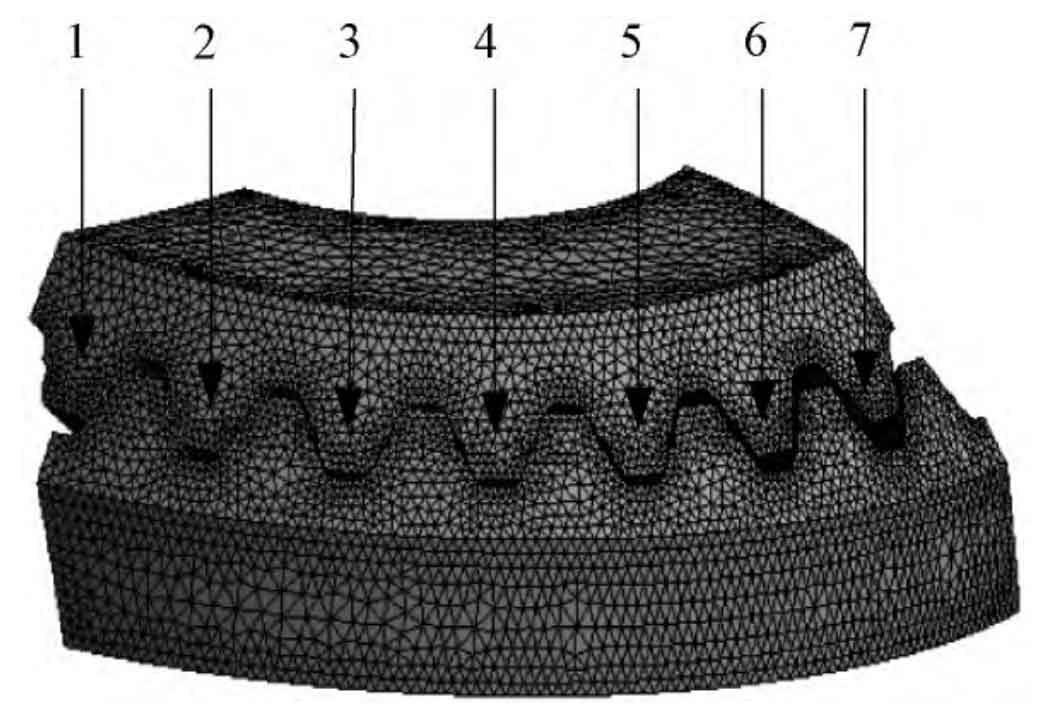

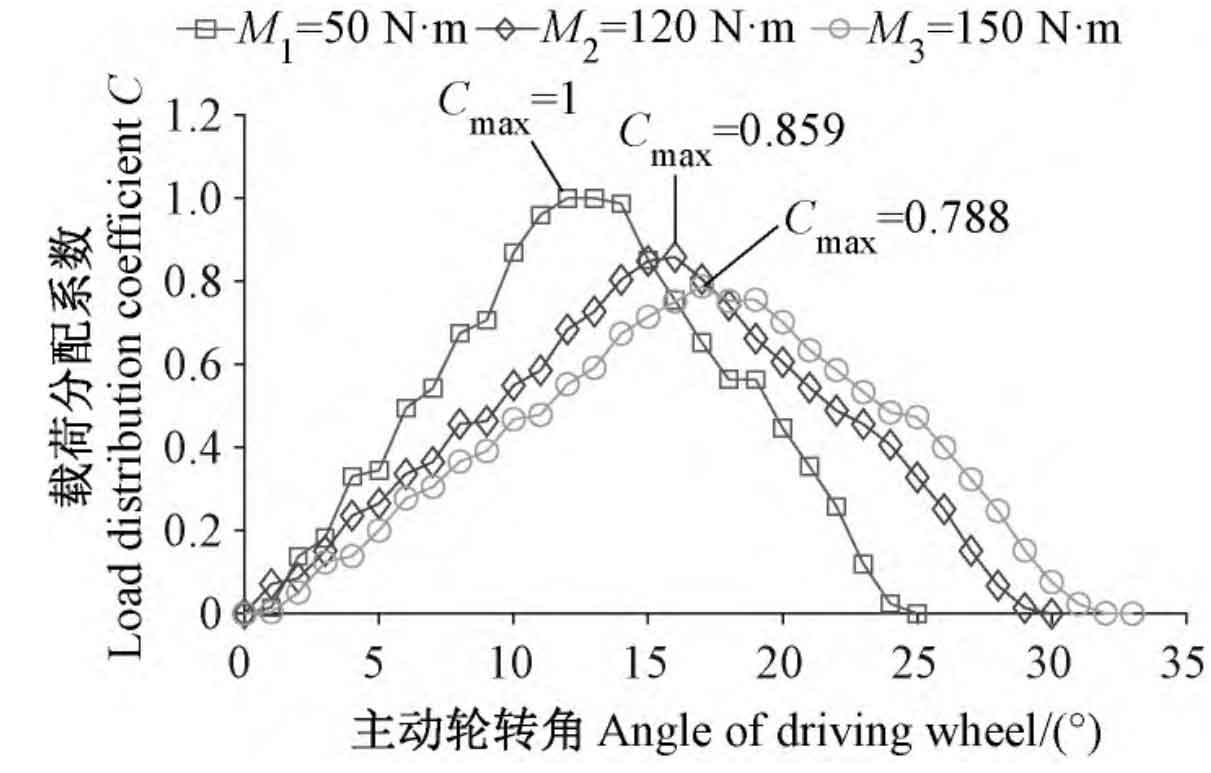

Taking the No. 4 tooth in Figure 1 as the analysis object, the tooth surface contact force of No. 4 tooth and the total contact force of multiple pairs of meshing double-arc spiral bevel gear teeth under one meshing cycle are extracted respectively in the finite element post-processing. The load distribution coefficient of No. 4 tooth can be obtained by using formula (6). In order to explore the influence of different loads on the load distribution coefficient, the load distribution coefficient of No. 4 gear under three loads was calculated, and the results are shown in Figure 2. Where, M1=50 N · m, M2=120 N · m, M3=150 N · m.

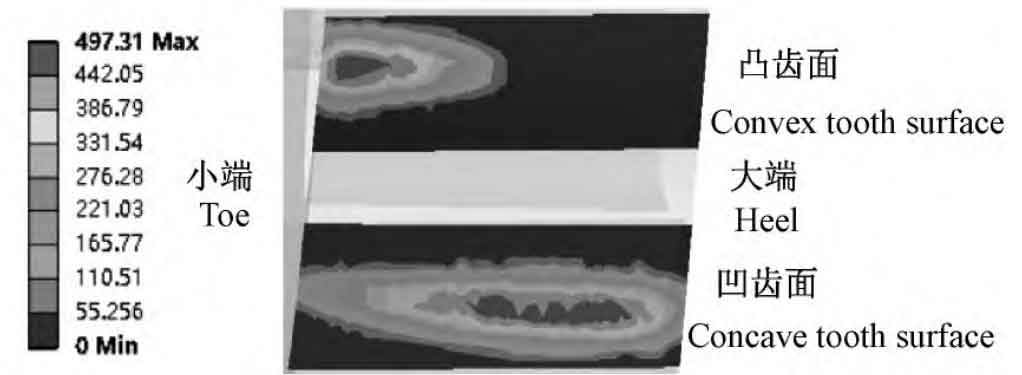

It can be seen from Figure 2 that the change trend of the load distribution coefficient of No. 4 tooth in a meshing cycle is the same as that of the tooth surface contact force in Figure 3. When the load distribution coefficient is the maximum, the load distributed by the gear teeth is the maximum. At this time, the concave and convex tooth surfaces of the double-arc spiral bevel gear teeth are in contact, as shown in Figure 4. However, under three different loads, the peak value of load distribution coefficient is different, which is 1 and 0 859 and 0 788。 This is because, with the increase of load, the tooth surface contact deformation of gear teeth increases, which increases the number of gear teeth involved in meshing, and the multi-tooth meshing effect is more significant. It can be seen that this is contrary to the change rule of coincidence degree, that is, with the increase of load, the peak value of load distribution coefficient gradually decreases.