1.Calculation of contact stress of cylindrical gear

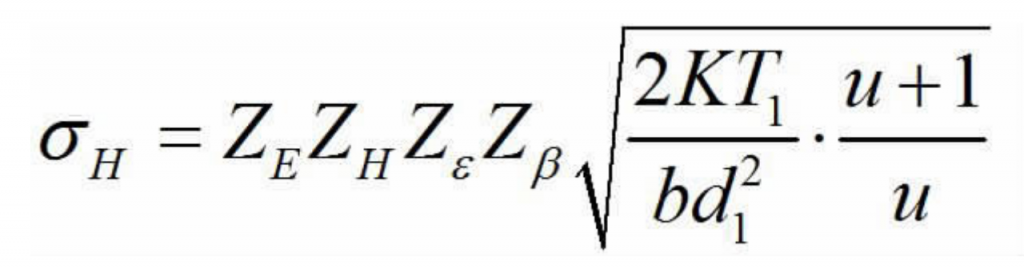

The transmission gear is a cylindrical gear. During the meshing process of the transmission gear, the maximum contact stress on the tooth surface of the cylindrical gear σ H occurs on the pinion. Taking the dynamic output torque of the permanent magnet synchronous motor as the driving torque of the high-speed cylindrical gear, and referring to the calculation method of the contact stress on the tooth surface of the spur gear, the cylindrical gear is converted into an equivalent spur gear for calculation. The formula is as follows:

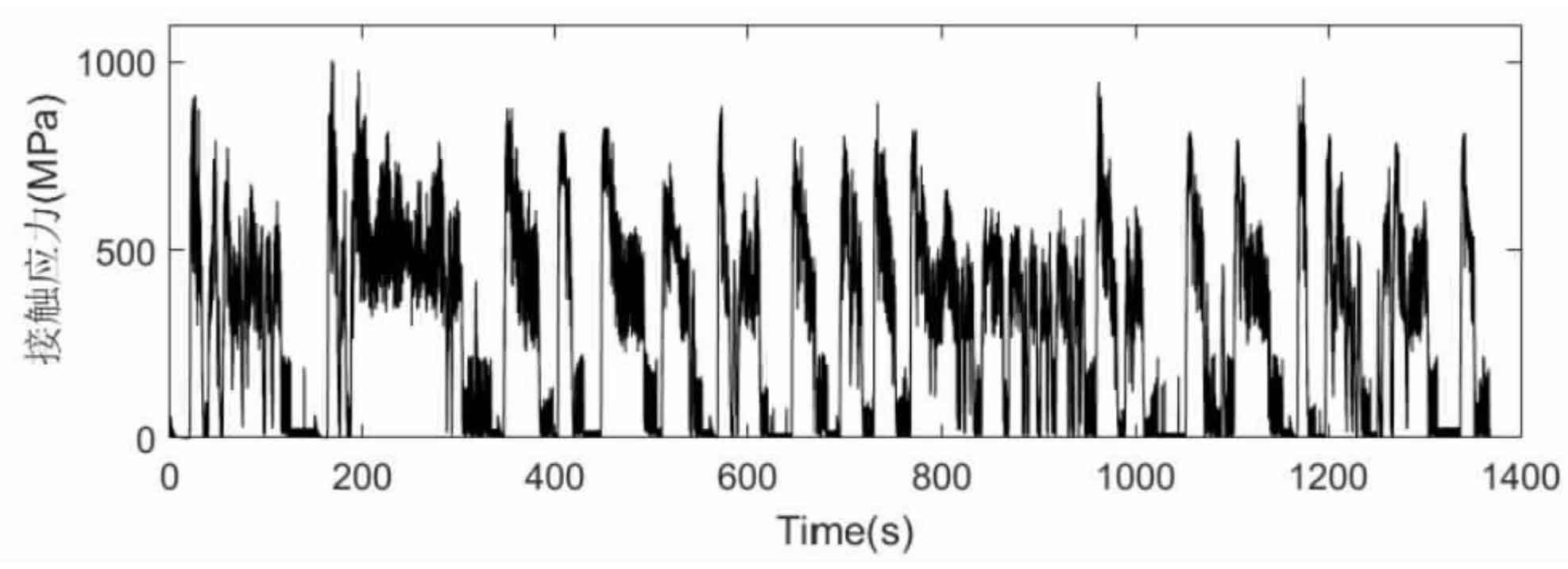

Calculate the contact stress of driving gear and get the contact stress spectrum of cylindrical gear under cyclic conditions, as shown in the figure 1.

2.Mean value frequency of contact stress amplitude of cylindrical gear

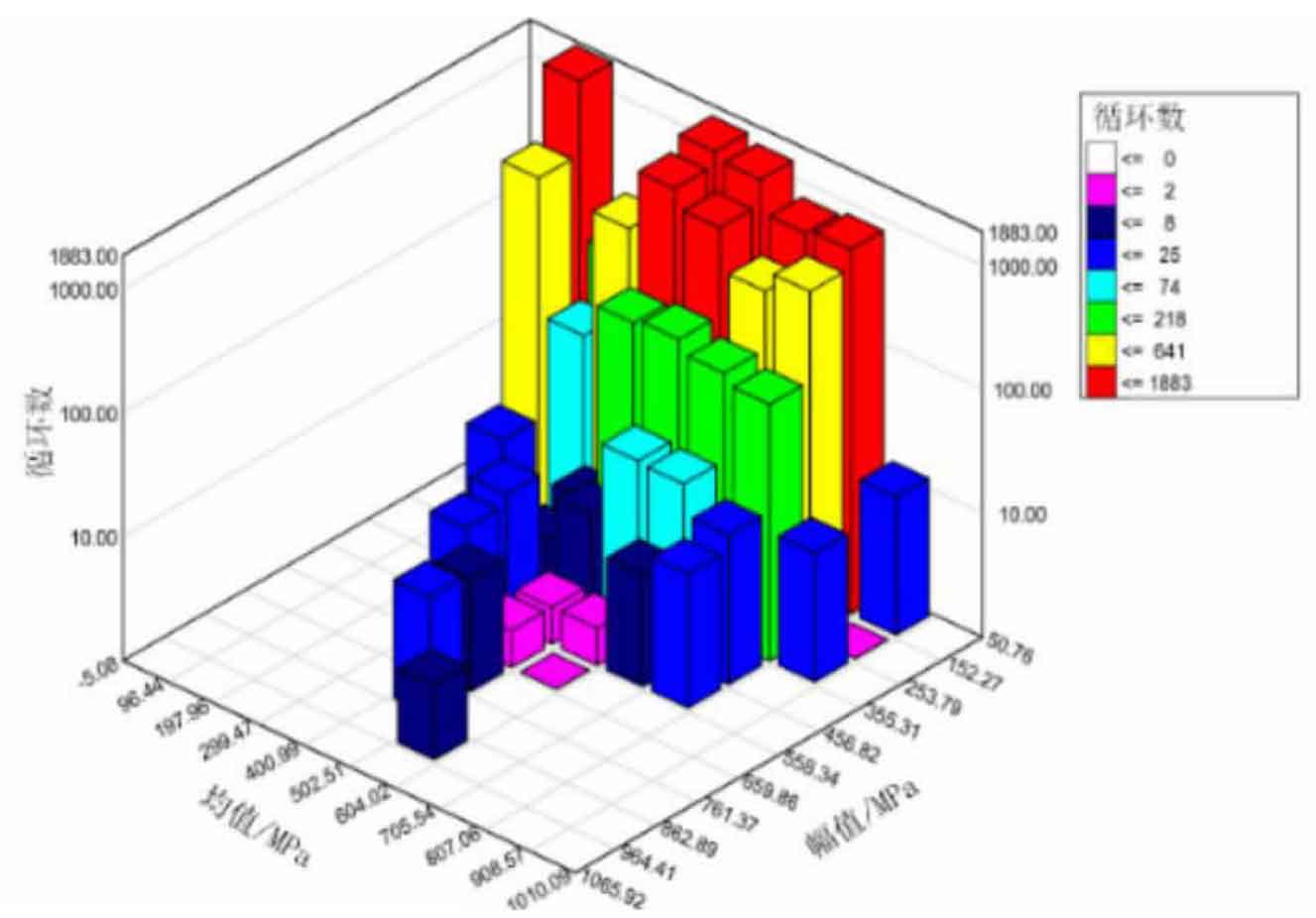

The essence of cycle counting method is to study the occurrence times of load basic damage elements from the perspective of fatigue damage, and establish a relationship between the counting process of load and the fatigue characteristics of materials.

At present, rain flow counting method is a random load cycle counting method that is generally considered by scholars at home and abroad to conform to the fatigue damage law, and has been widely used in engineering practice. The rain flow counting method is used to count the contact stress spectrum of the cylindrical gear. Figure 2 shows the mean value frequency of the contact stress amplitude of the high-speed cylindrical gear of the electric vehicle transmission. Through statistical analysis and K-S hypothesis test of the counting results, it can be seen that the average load follows the normal distribution, and the load amplitude follows the Weibull distribution. The mean value and standard deviation of the mean distribution of contact stress of cylindrical gears are 508mpa and 82.3mpa respectively.