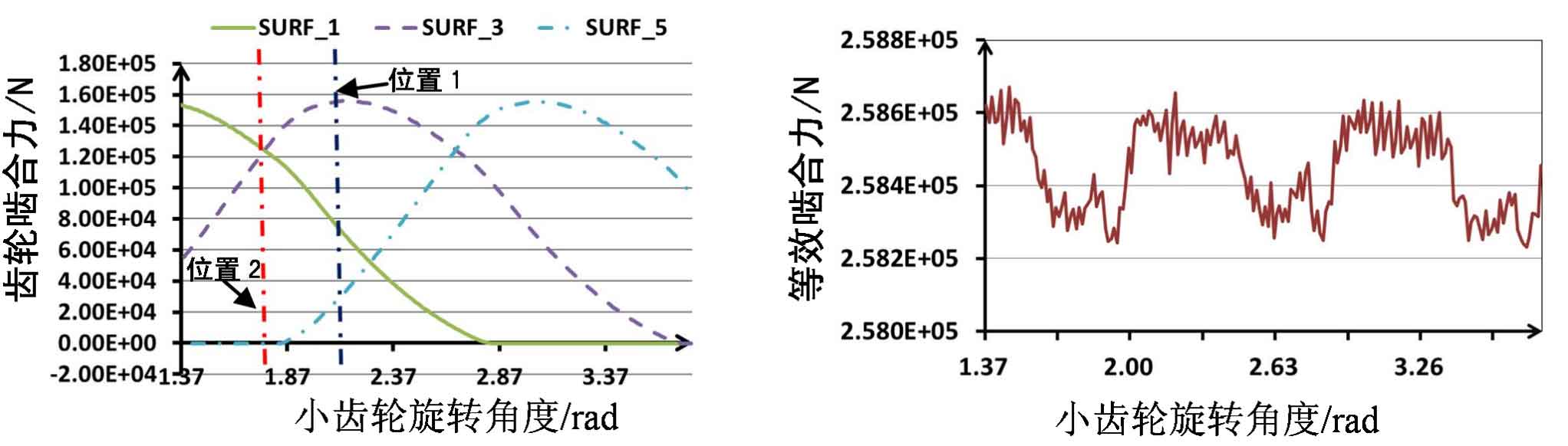

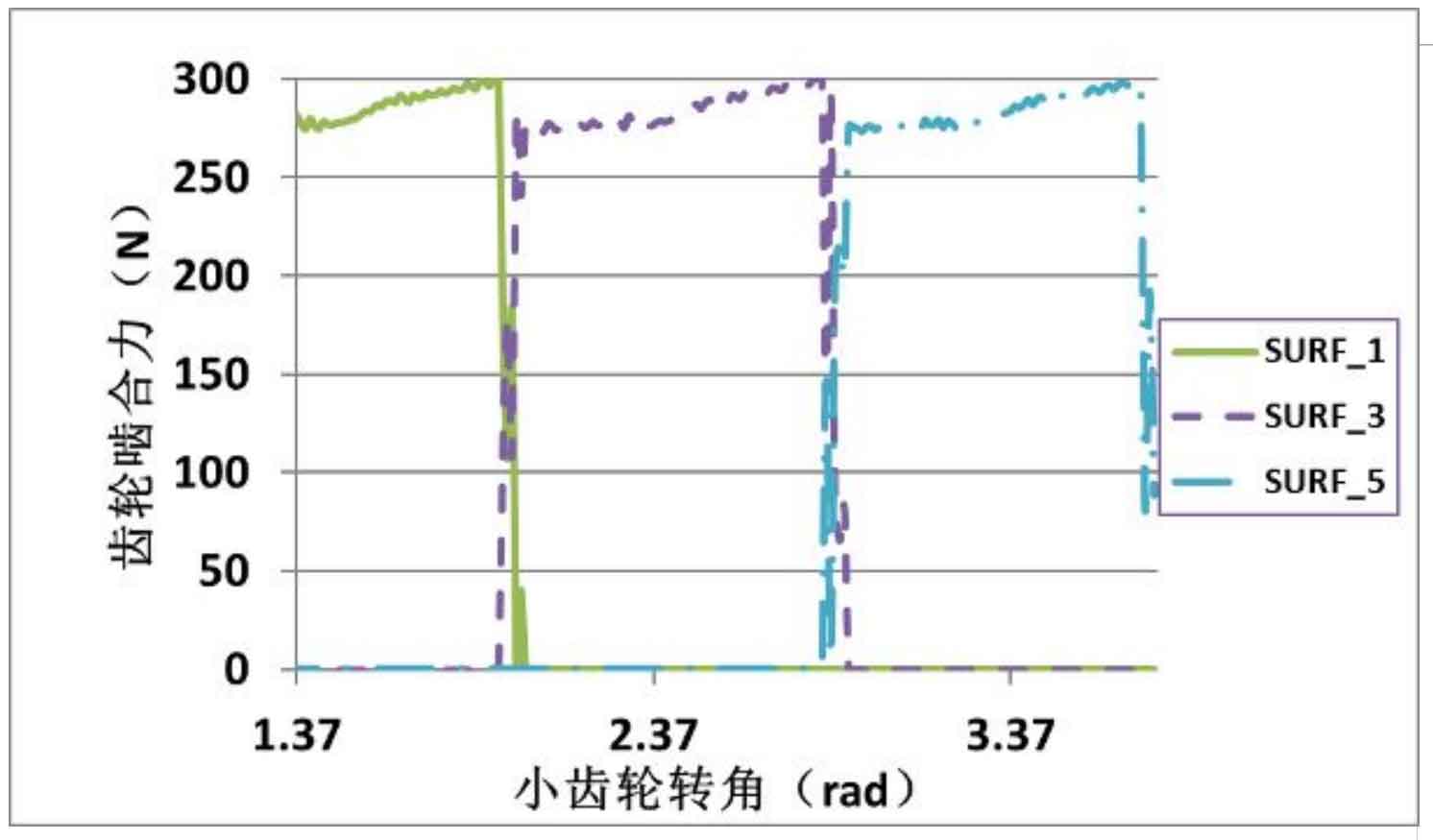

Conduct contact analysis (LTCA) on the hypoid gear under load. The resistance torque applied at the output end of the large gear is 9000nm, as shown in Fig. 1 (a), which is the change process of single gear meshing force. The definition of surf-i is the same as that in Fig. 2. The green dotted line (position 1) in the figure shows that the corresponding gear teeth of SURF-1 exit the mesh, and the corresponding gear teeth of surf-5 enter the mesh. At this time, three gear teeth are in mesh, Only the hypoid gears corresponding to surf-3 and surf-5 participate in the meshing at the red dot chain line (position 2) in the figure. Unlike spur gears, the direction of meshing force of adjacent meshing teeth at any time is different.

Because the direction of the meshing force of the hypoid gear changes with the rotation angle of the gear, the meshing force of the hypoid gear at any time cannot be obtained by simply adding the normal meshing force of the meshing hypoid gear. It is necessary to vector add the meshing force of the hypoid gear at the same time to obtain the normal meshing force of the hypoid gear at any meshing time as shown in Fig. 1 (b), It can be seen from the figure that the meshing force changes periodically with the rotation angle of the gear.

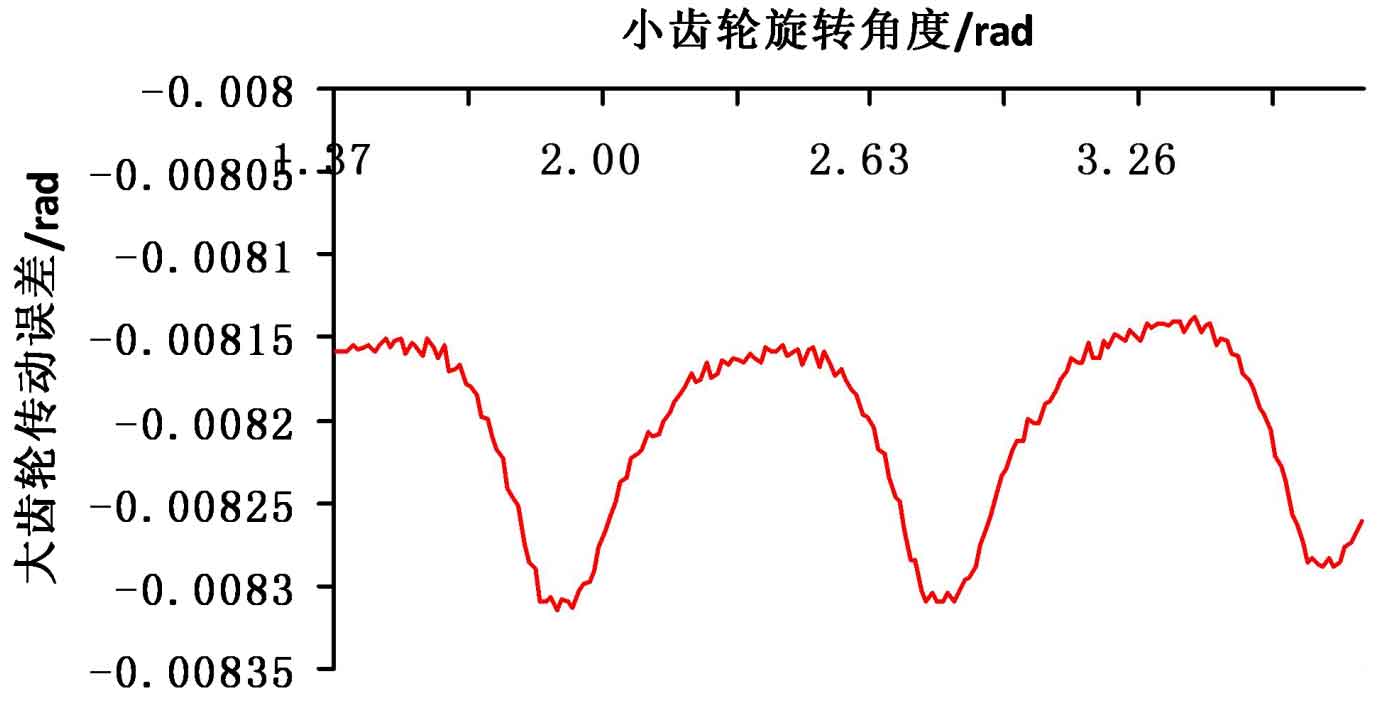

The transmission error of large load can be obtained by using the formula as shown in Fig. 3. It can be seen that the transmission error of hypoid gear shows periodic change and also maintains parabolic shape. Compared with the transmission error of hypoid gear under small load, the transmission error of hypoid gear corresponding to large load translates downward correspondingly, and the fluctuation degree of adjacent simulation values of transmission error is smaller than that under small load, This is because the tooth blank and tooth surface contact of the hypoid gear have large deformation under the action of large load, which increases the average value and peak value of the transmission error. Moreover, the contact of the hypoid gear is more stable due to the increase of the loaded force, which makes the operation of the hypoid gear more stable under the action of large load.