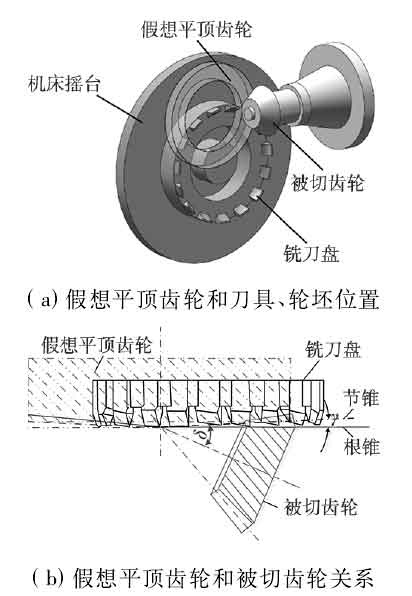

The cutting of spiral bevel gear is carried out according to the principle of “imaginary flat top gear”. As shown in Fig. 1, the “imaginary gear” cutting principle of spiral bevel gear is shown, and Fig. 1a is the position of imaginary flat top gear, cutter and wheel blank.

When adjusting the gear cutting machine tool, the pitch cone surface of the gear to be cut must be tangent to the pitch cone surface of the imaginary flat top gear, and the rotation plane of the cutter head must be tangent to the root cone of the gear to be cut. The relationship between the imaginary flat top gear and the gear to be cut is shown in Fig. 1b. Therefore, the axis of the milling cutter head and the pitch cone of the gear to be cut are inclined by an angle equal to the root angle γ of the tooth to be cut.