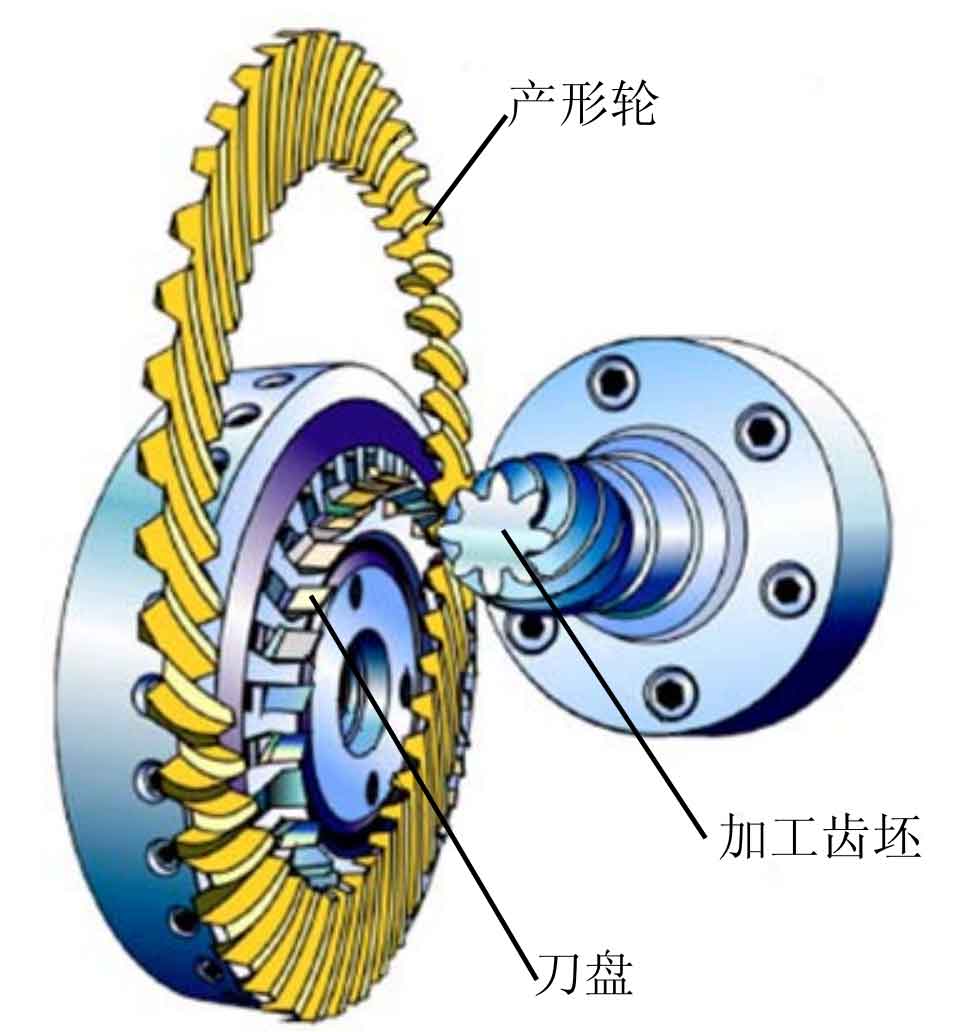

The traditional mechanical hypoid gear milling machine processes spiral bevel gears and hypoid gears using the generating wheel principle shown in the figure. The traditional mechanical hypoid gear milling machine has its unique shaking table mechanism. The function of this mechanism is to drive the milling cutter head to simulate the movement of an imaginary gear (i.e. generating wheel), which is concentric with the shaking table mechanism. The milling cutter head for machining tooth surface is installed on the shaking table mechanism. During its rotation, the space track surface of the cutting edge of the milling cutter head replaces the tooth surface of the generating wheel. When machining the tooth surface, the blank of the gear to be machined and the shaping wheel simulate the meshing process of an hypoid gear. The two rotate around each other with their own rotation axis as the center according to the preset transmission ratio, and the cutting edge surface of the cutter head gradually cuts the tooth shape on the blank of the gear to be cut in the way of full conjugate meshing with the machined tooth surface. This machining method of spiral bevel gears and hypoid gears is called generating method.

(1) When machining hypoid gear pairs, the axis of the big wheel cutter head is perpendicular to the big wheel root cone, and the axis of the small wheel cutter head is perpendicular to the small wheel surface cone. In this way, the axes of the big wheel and the small wheel cutter head are parallel to each other, which can essentially avoid the phenomenon of diagonal contact in the theoretical contact area.

(2) When machining the small wheel, the spiral motion can be used to machine the tooth surface and the tooth root surface at the same time, so as to obtain the contracted teeth. The mismatch in the direction of tooth length is achieved by correcting the radius of the fine cutting cutter head of the small wheel; The denaturation coefficient is used to achieve the mismatch in the direction of tooth height.

(3) Machining hypoid gear pairs by spiral denaturing semi generating method simplifies the complex adjustment and correction process of the previous machining methods to avoid diagonal contact in the contact area.