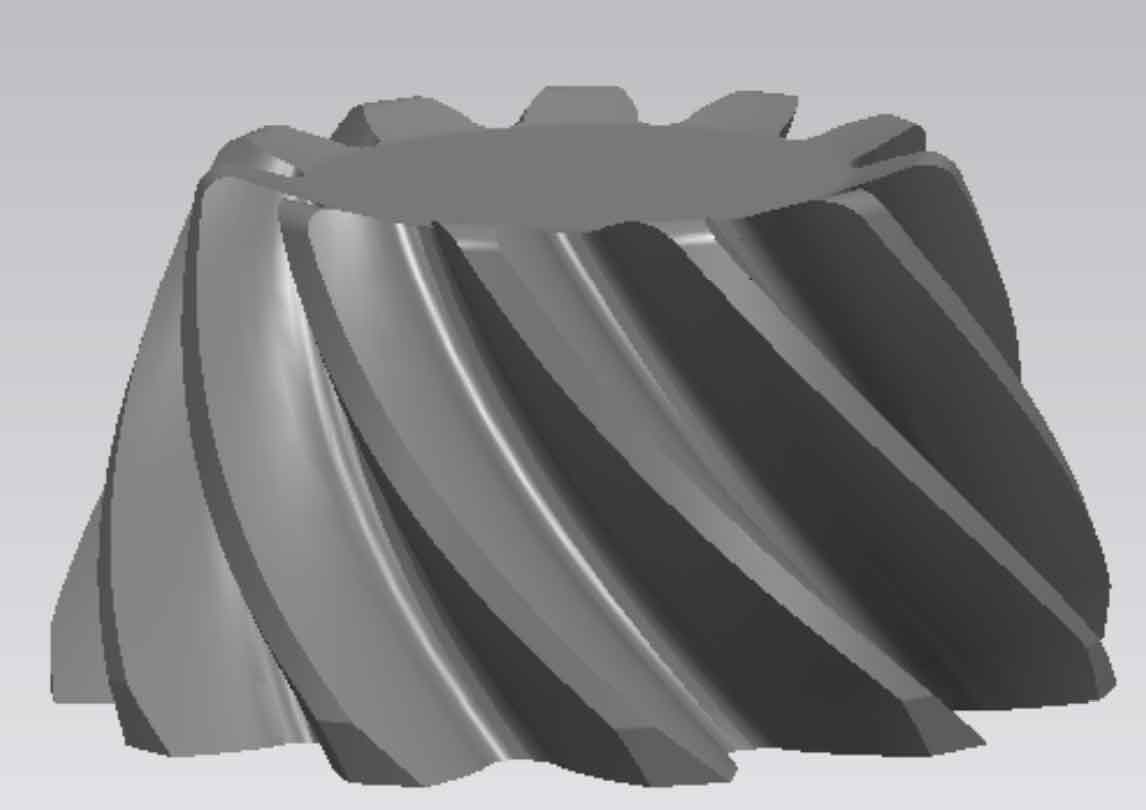

Spiral bevel gear transmission is to transmit the motion and power between any two shafts in space through the meshing of teeth, and can change the form and speed of motion. Spiral bevel gear transmission has a wide range of use, constant transmission ratio, high efficiency and long service life. In the design and manufacturing process of mechanical parts, not only the performance of materials should be considered to adapt to the working conditions of parts, In order to make the parts durable, the materials are required to have better processing performance and economy, so as to improve the productivity of the parts, reduce the cost and reduce the consumption. If the spiral bevel gear materials are not selected properly, the parts will be damaged or even fail too early. Therefore, we should be careful in gear selection.

First of all, the mechanical properties of the material should be satisfied: the mechanical properties of the material include strength, hardness, plasticity and toughness, which reflect the characteristics of the material in the use process. When the gear is meshed, there is contact stress at the contact point of the tooth surface, and there is bending stress at the root of the tooth, which may lead to the failure of the strength of the tooth surface or the tooth body. Each point of the tooth surface has relative sliding, which will produce wear. The main failure forms of gears are pitting, gluing, plastic deformation and fracture. Therefore, the gear material is required to have high bending fatigue strength and contact fatigue strength, sufficient hardness and wear resistance of the tooth surface, and certain strength and toughness of the core.

Secondly, to meet the technological performance of materials: the technological performance of materials refers to the ability of materials to adapt to various processing requirements. The manufacturing of gears should be processed by forging, cutting and heat treatment. Therefore, attention should be paid to the technological properties of materials when selecting materials.

Third, the economic requirements of materials: the so-called economy refers to the small cost to obtain large economic benefits. On the premise of satisfying the service performance, the total cost of parts should be reduced as much as possible when selecting gear materials.

To sum up, when choosing spiral bevel gear materials, we should start from the reality and comprehensively consider the mechanical performance, technological performance and economy. Only reasonable selection of materials can guarantee the quality of gears and reduce the cost of products, so as to improve the market competitiveness.