1. Experimental materials

The experimental material is SAEJ403 carbon steel. The chemical composition of SAE J403 carbon steel is shown in the table. Quench SAE J403 carbon steel gear, and the quenching process mainly includes eddy current quenching, cooling and 150 ℃ tempering; After that, the un quenched carbon steel gears and quenched gears with different thicknesses (2, 3, 4, 6, 8 mm) were sampled and processed with a wire EDM machine to obtain ultrasonic test samples. The sample size is 25mm long, 20mm wide and 15mm thick.

| C | Mn | Si | P | S | Ni | Cr | Mo | Fe |

| 0.53 | 1.38 | 0.16 | 0.028 | 0.033 | 0.16 | 0.18 | 0.05 | Allowance |

2. Ultrasonic testing

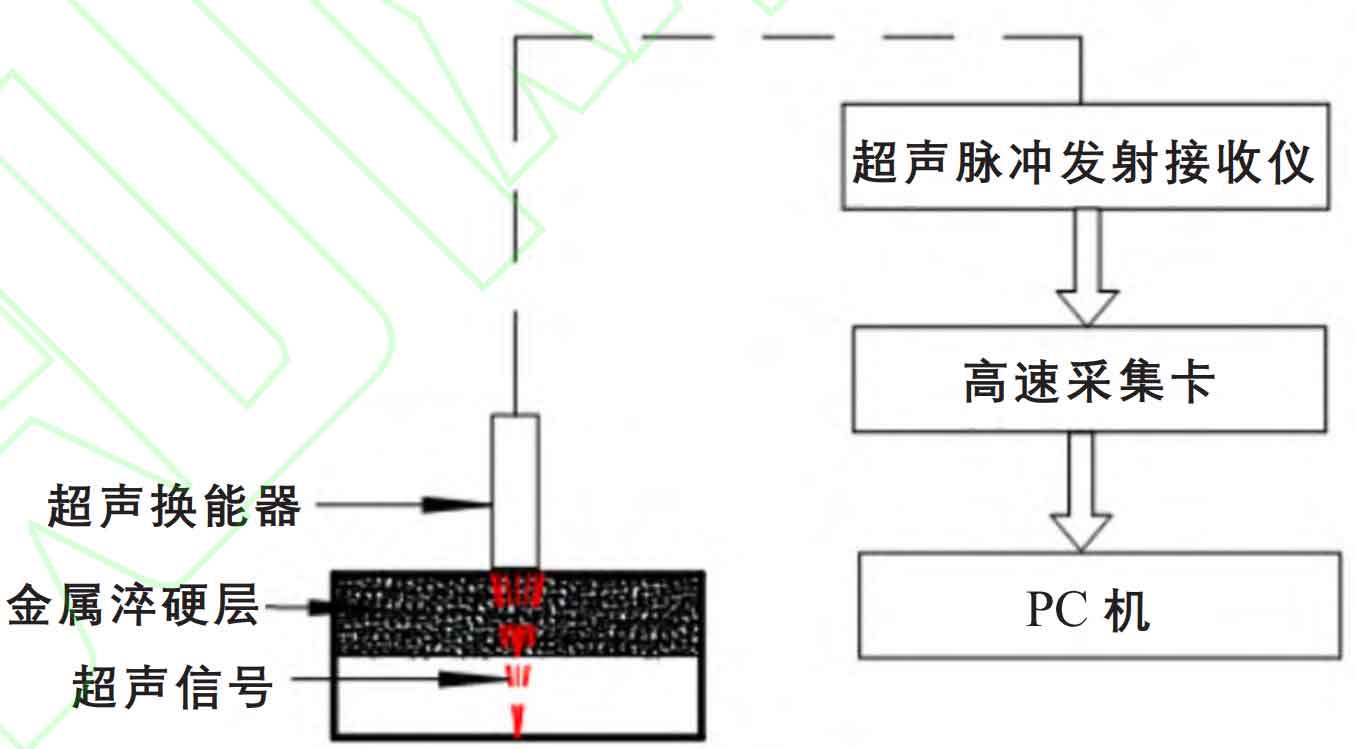

Figure 1 is the schematic diagram of ultrasonic signal acquisition device. The detection device is mainly composed of OLYMPUS ultrasonic transducer (5MHz), OLYMPUS ultrasonic signal transmitter and receiver, PCI-5114 high-speed A/D acquisition card and PC. The ultrasonic signal is transmitted by the ultrasonic transducer into the hardened layer carbon steel, and the ultrasonic signal is obtained by the ultrasonic pulse emission receiver. The ultrasonic signal is collected by the high-speed acquisition card pair and transmitted to the PC to complete the ultrasonic testing experiment.

3. Metallographic inspection

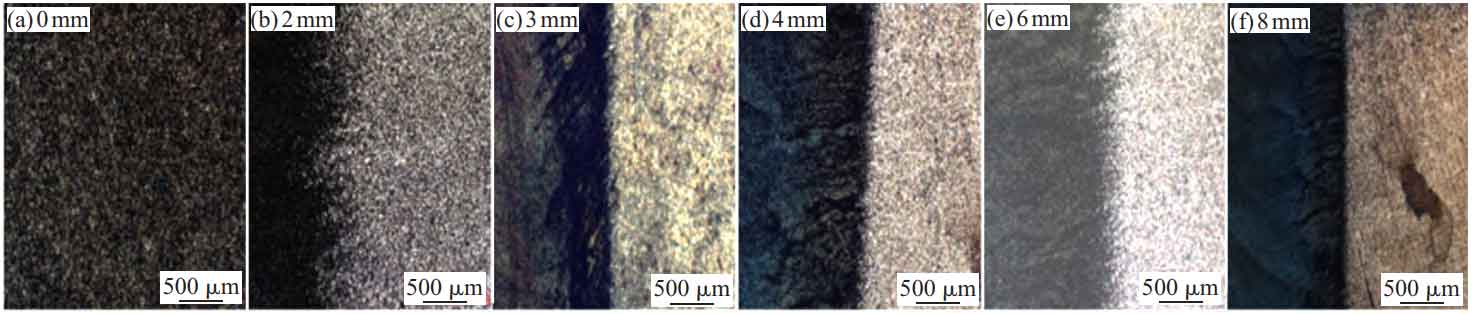

In order to ensure the test results, the test samples were cut, polished and electroetched with oxalic acid as electrolyte, and then the processed samples were observed with KEENS VHX7000 electron microscope. Fig. 2 shows the metallographic diagram of samples with different thicknesses of hardened layers. From the metallographic diagram, it can be found that the surface grain density of carbon steel after quenching is larger, the grain size is relatively small, and the surface grain structure of carbon steel without quenching treatment is relatively small, and the grain density is also low. With the increasing of the hardened layer thickness, the delamination of carbon steel surface is relatively obvious.