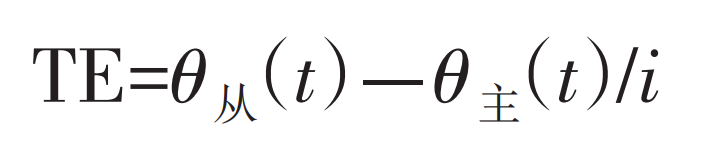

Transmission error (TE) is the main source of noise of spiral bevel gear system. Studying the transmission error of spiral bevel gear has guiding significance for optimizing structural design and reducing vibration and noise. The transmission ratio of the first contact point of the spiral bevel gear when two tooth surfaces contact is equal to the theoretical value, which is Z2 Z1. Then the contact continues, and the transmission ratio of the following contact points will deviate from the theoretical value. It is known that the small wheel is the driving wheel and the big wheel is the driven wheel. If the transmission ratio is always constant and the size is equal to the theoretical value, then when the angle of the driving wheel is equal to θ The turning angle of the driven wheel is θ From=Z2/Z1 • θ Master. When the transmission ratio of each contact point in the transmission process deviates from the theoretical value, θ From=Z2/Z1 • θ Master. At this time, the deviation between the theoretical value and the actual rotation angle can be expressed by the formula.

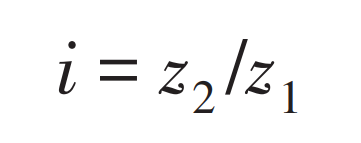

Where: θ Main (t) – angle change of driving wheel (pinion); θ From (t) – angle change of driven wheel (big gear); I – transmission ratio of two gears, as shown in the formula.

Where: Z1, Z2 – number of teeth of large and small spiral bevel gears.