1. Introduction

Hypoid gears play a crucial role in mechanical transmissions, especially in automotive applications. They offer several advantages such as high load-carrying capacity, efficient power transmission, smooth operation, low noise, and large reduction ratios. The study of hypoid gears is of great practical significance and value. In recent years, many scholars have conducted research on various aspects of hypoid gears, including cutting design, processing methods, and installation errors. This article focuses on deriving a mathematical model for hobbing hypoid gears based on the Spiroflex method and validating its accuracy.

1.1 The Importance of Hypoid Gears

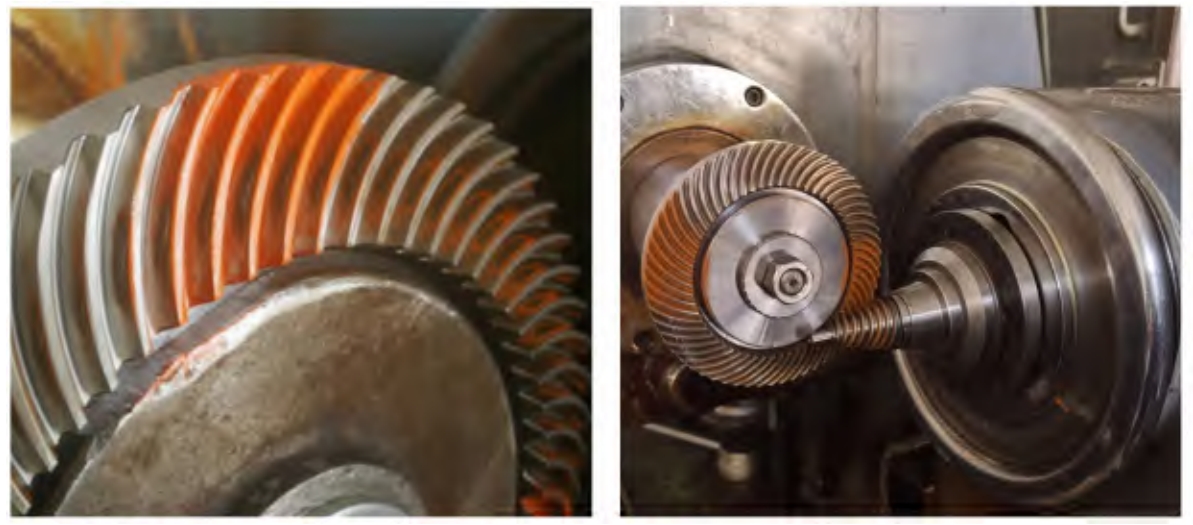

Hypoid gears are widely used in automotive main reducers and are key components in drive axles. Compared to spiral bevel gears, hypoid gears have an offset distance between the large and small wheels, which enhances the vehicle’s stability and off-road performance. Additionally, the relative sliding along the tooth length and height directions of hypoid gears facilitates running-in, grinding after heat treatment, and improvement of the tooth surface contact area, as well as an increase in tooth surface finish and a reduction in noise.

1.2 Previous Research on Hypoid Gears

- Shih et al. proposed a mathematical model for a universal face hobbing hypoid gear generator to simulate the cutting motions of different tooth systems.

- Wang et al. developed a method to convert the mechanical settings of a universal cradle-type machine to those suitable for a 6-axis machine in a Cartesian coordinate system.

- Takeda et al. analyzed the meshing performance of hypoid gears and measured the transmission errors through experiments.

- Dong introduced the meshing theory and milling principles of spiral bevel gears and hypoid gears and sorted out the design and adjustment methods of face hobbing for different tooth systems.

- Fang conducted preliminary theoretical exploration on the optimal cutting design of hypoid gears using the local synthesis method.

- Tang derived the working tooth surface equation and transition surface equation for hypoid gears based on a cradle machine, providing an accurate geometric model for tooth contact analysis.

2. Mathematical Model for Hobbing Hypoid Gears Based on Spiroflex Method

2.1 Face Hobbing Cutter Mathematical Equations

- Cutter Geometry: The face hobbing cutter for hypoid gears consists of several strip-shaped cutting edges. It can have up to three types of cutting edges: inner cutter, middle cutter, and outer cutter. The middle cutter is often used for rough cutting, while the inner cutter cuts the convex surface of the gear and the outer cutter cuts the concave surface. When machining left-handed gears, a left-handed cutter is used, and for right-handed gears, a right-handed cutter is used.

- Equations of the Cutting Edge: In a coordinate system S1, the position vector of the cutting edge is represented by homogeneous coordinates as τ1(u). The cutting edge is composed of a rounded part τ1^(f)(u) and a straight part τ1^(I)(u). The equations for the straight part are , and for the rounded part are , where is the center of the round, , corresponds to the inner and outer cutters, is the cutter tooth profile angle, is the reference point height, is the round radius, and is the cutting edge parameter.

- Coordinate Transformation: The cutting edge equation in the coordinate system is transformed to the cutter coordinate system to obtain the position vector of the cutting edge in the cutter coordinate system as , where , , are coordinate transformation matrices related to the cutter’s initial setting angle, reference point radius, and direction angle.

2.2 Face Hobbing Hypoid Gear Tooth Surface Mathematical Model

- Machine Settings and Coordinate Systems: The mechanical settings of a face hobbing hypoid gear cutting machine are calculated based on relevant literature. The positions of the cutter, imaginary generating wheel, and workpiece gear in the coordinate system of a universal cradle-type machine are described. The coordinate system is fixed to the cutter, is fixed to the imaginary generating wheel, and is fixed to the workpiece gear.

- Imaginary Generating Wheel Tooth Surface Equation: The tooth surface equation of the imaginary generating wheel is obtained by transforming the cutting edge equation from the cutter coordinate system to the generating wheel coordinate system as , where , , , are coordinate transformation matrices related to the rotation angle of the cycloidal motion, the setting angle of the cutter tilt direction, the cutter tilt angle, and the cutter rotation angle.

- Tool Edge Trajectory Equation in Workpiece Coordinate System: To obtain the tool edge trajectory equation observed from the workpiece coordinate system , the generating wheel tooth surface position equation in the coordinate system is transformed to the workpiece coordinate system as , where , , , are coordinate transformation matrices related to the workpiece rotation angle, mechanical root angle, horizontal and vertical wheel positions, and generating motion cradle angle.

- Meshing Equation and Tooth Surface Topological Points: The meshing equation is derived based on the tool edge trajectory equation as . By solving this equation with the constraints provided by the tooth surface topological points, the positions and unit normal vectors of the tooth surface topological points of the hypoid gear can be obtained as

3. 6-Axis CNC Hypoid Gear Cutting Machine Mechanical Settings

3.1 Coordinate Transformation Matrix

The coordinate transformation matrix between the cutter and the workpiece for a 6-axis CNC hypoid gear cutting machine is expressed as , where , , , , , , are coordinate transformation matrices related to the workpiece rotation angle, the increment of the workpiece rotation axis angle, the mechanical constant, the workpiece inclination angle, the cutter displacement, the increment of the cutter rotation axis angle, and the cutter rotation angle.

3.2 Mechanical Setting Conversion

To ensure that the gear tooth surface processed on a 6-axis CNC machine is the same as that on a traditional cradle-type machine, the coordinate transformation matrix from the cutter coordinate system to the workpiece coordinate system in both machines must be consistent. By equating the matrices and and solving for the elements, the mechanical settings suitable for the 6-axis CNC cutting machine can be obtained. The workpiece rotation angle increment and the workpiece inclination angle can be calculated as , and the displacements of three axes can be calculated as . In addition, the workpiece rotation axis inclination angle is calculated as .

4. Experimental Verification of Hypoid Gear Face Hobbing

4.1 Gear and Cutter Parameters

The basic parameters and tooth blank parameters of the hypoid gears, as well as the cutter parameters and the mechanical parameters of the cradle-type machine, are listed in tables. For example, the basic parameters of the small and large gears include the number of teeth, reference point normal modulus, reference point spiral angle, reference point pressure angle, shaft intersection angle, offset distance, pitch cone angle, tooth surface width, and pitch circle diameter. The cutter parameters include the number of cutter groups, reference point height, tooth profile angle, direction angle, cutter reference point radius, and initial setting angle. The mechanical parameters of the cradle-type machine include the cutter tilt angle, cutter tilt direction setting angle, cutter position radius, cradle initial setting angle, vertical and horizontal wheel positions, bed position, and mechanical root angle.

4.2 Model Generation and Processing

Using the above parameters, the tooth surface mathematical model of the hypoid gear is derived, and the positions of the tooth surface points and their unit normal vectors are solved. Then, a 3D model of the hypoid gear pair is generated using SolidWorks software based on the tooth surface topological point positions and the gear pair assembly parameters. After converting the mechanical parameters of the cradle-type machine to those of the 6-axis CNC machine, the workpiece processing coordinate positions are calculated and an NC machining program is planned for actual gear processing. At the same time, the face hobbing process of the hypoid gear is simulated using VERICUT software, and the tooth surface error analysis is carried out between the simulation result and the theoretical gear.

4.3 Error Analysis Results

The actual tooth thickness of the small gear is 7.509 mm with a tooth thickness error of +3.8 μm, and the actual tooth thickness of the large gear is 6.701 mm with a tooth thickness error of -39.62 μm. The maximum error of the tooth surface point positions for both the small and large gears is about 30 μm. According to the general experience of VERICUT cutting simulation, the tooth surface point position errors and tooth thickness errors between the theoretical tooth surface and the cutting simulation gear are mostly less than 50 μm. These results verify the high accuracy of the proposed mathematical model for face hobbing hypoid gears on a 6-axis CNC hypoid gear cutting machine.

5. Conclusion

In this article, a mathematical model for hobbing hypoid gears based on the Spiroflex method is established on a cradle-type machine. The conversion of mechanical settings from a universal machine to a 6-axis CNC machine is achieved, enabling the face hobbing method to be applicable for hypoid gear processing on a new 6-axis CNC hypoid gear cutting machine. Through VERICUT cutting simulation software, the tooth surface point position errors and tooth thickness errors between the simulation workpiece gear and the theoretical gear are analyzed, and the errors are found to be less than 50 μm, validating the correctness of the proposed mathematical model. This research provides a theoretical basis and practical guidance for the accurate processing of hypoid gears.