To maximize gear efficiency, leveraging the power of a gear calculator is crucial. A gear calculator enables you to analyze various parameters and make informed design decisions that optimize gear efficiency. Here’s how you can use a gear calculator to maximize gear efficiency:

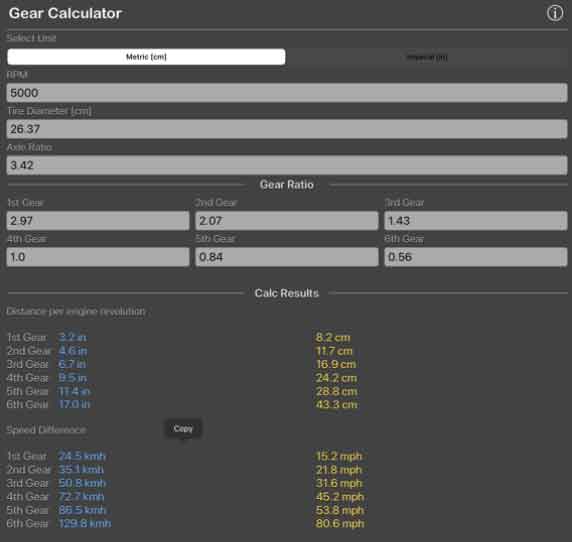

- Input Design Parameters: Enter the relevant design parameters into the gear calculator. This includes the gear specifications such as module, pressure angle, number of teeth, and center distance. Additionally, input operating conditions such as input speed, output speed, and power transmission requirements.

- Calculate Gear Ratios: Use the gear calculator to calculate the required gear ratios based on the input and output speeds. Gear ratios impact the speed and torque relationship between the driving and driven gears. By optimizing the gear ratios, you can achieve the desired balance between speed and torque, minimizing energy losses and maximizing gear efficiency.

- Evaluate Tooth Profiles: The gear calculator allows you to evaluate and optimize tooth profiles, such as involute profiles for spur gears or helical profiles for helical gears. These profiles affect the contact area, load distribution, and meshing efficiency. By fine-tuning the tooth profiles through the gear calculator, you can minimize friction and ensure efficient power transmission.

- Analyze Load Distribution: Utilize the gear calculator to analyze load distribution across the gear teeth. Uneven load distribution can lead to premature wear and reduced efficiency. The calculator helps identify areas of high contact stresses and allows you to optimize the gear dimensions and tooth modifications to achieve uniform load distribution, enhancing gear efficiency and longevity.

- Consider Lubrication Effects: Gear calculators often provide options to account for lubrication effects. Proper lubrication reduces friction and wear, enhancing gear efficiency. The gear calculator can help estimate the impact of different lubrication parameters, such as viscosity and film thickness, on gear efficiency. Optimizing the lubrication conditions based on the calculator’s analysis can significantly improve gear efficiency.

- Iterative Optimization: The gear calculator facilitates an iterative optimization process. You can modify various parameters, such as gear dimensions, tooth profiles, and lubrication conditions, and observe the resulting changes in gear efficiency. By iteratively refining the design using the gear calculator, you can identify the most efficient gear configuration for your specific application.

- Compare Design Options: A gear calculator enables you to compare different design options by calculating and comparing their respective efficiencies. You can evaluate the impact of alternative tooth profiles, gear ratios, or materials on gear efficiency. This comparison allows you to make informed design decisions and select the most efficient gear configuration.

- Consider System-Level Factors: Gear efficiency is influenced by factors beyond the gear itself. For complex systems like gearboxes or transmissions, the gear calculator can assist in evaluating system-level effects such as bearing losses, oil churning losses, or mechanical losses due to seals and couplings. By considering these factors in conjunction with gear efficiency, you can optimize the overall system efficiency.

By leveraging the power of a gear calculator, you can optimize various design parameters, analyze load distribution, evaluate lubrication effects, and iterate on design improvements. This systematic approach allows you to maximize gear efficiency, resulting in reduced energy losses, improved performance, and enhanced overall system efficiency.