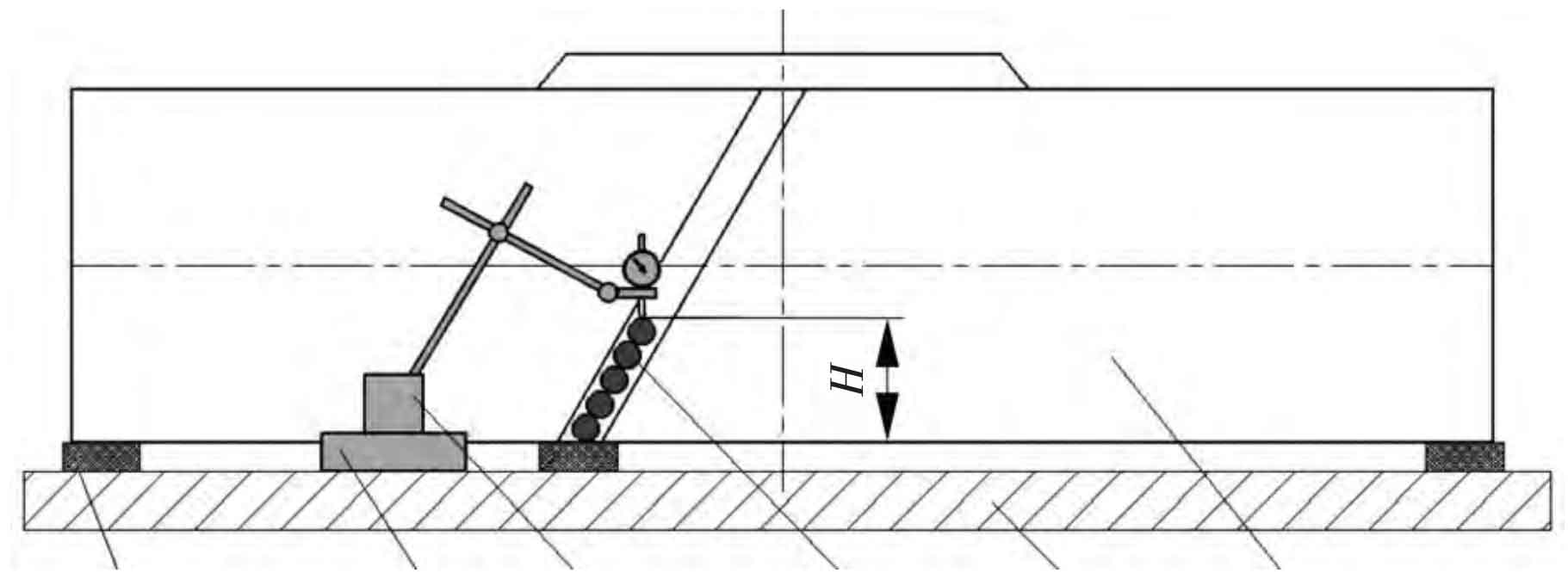

First, prepare a large inspection platform, several steel balls with the same diameter (if conditions permit, it is best to use the ball of large bearing, the size of the steel ball can make its contact point with the tooth surface on the effective involute tooth surface, and it is convenient to measure with a dial gauge), a box of measuring blocks, three equal height sizing blocks, a flat plate, a magnetic gauge base and a dial gauge. Place the involute helical cylindrical gear on the inspection platform and pad it with equal height sizing block. One sizing block is used to block the steel ball, place it at the bottom of the tooth groove, put multiple steel balls with diameter DP into the same tooth groove, and press gently by hand to ensure that each steel ball is in close contact with the involute helical cylindrical tooth surface on both sides, and the steel balls are in close contact with each other and the measuring reference plane. Put the magnetic meter base on the flat plate and push out the highest point of the steel ball repeatedly, and then the measuring block can measure the distance from the highest point of the steel ball to the sizing block to obtain the distance h of the head and tail steel balls along the axial direction of the involute helical cylindrical gear (i.e. the height difference between the top of the steel ball and the measurement reference plane), as shown in Figure 1.

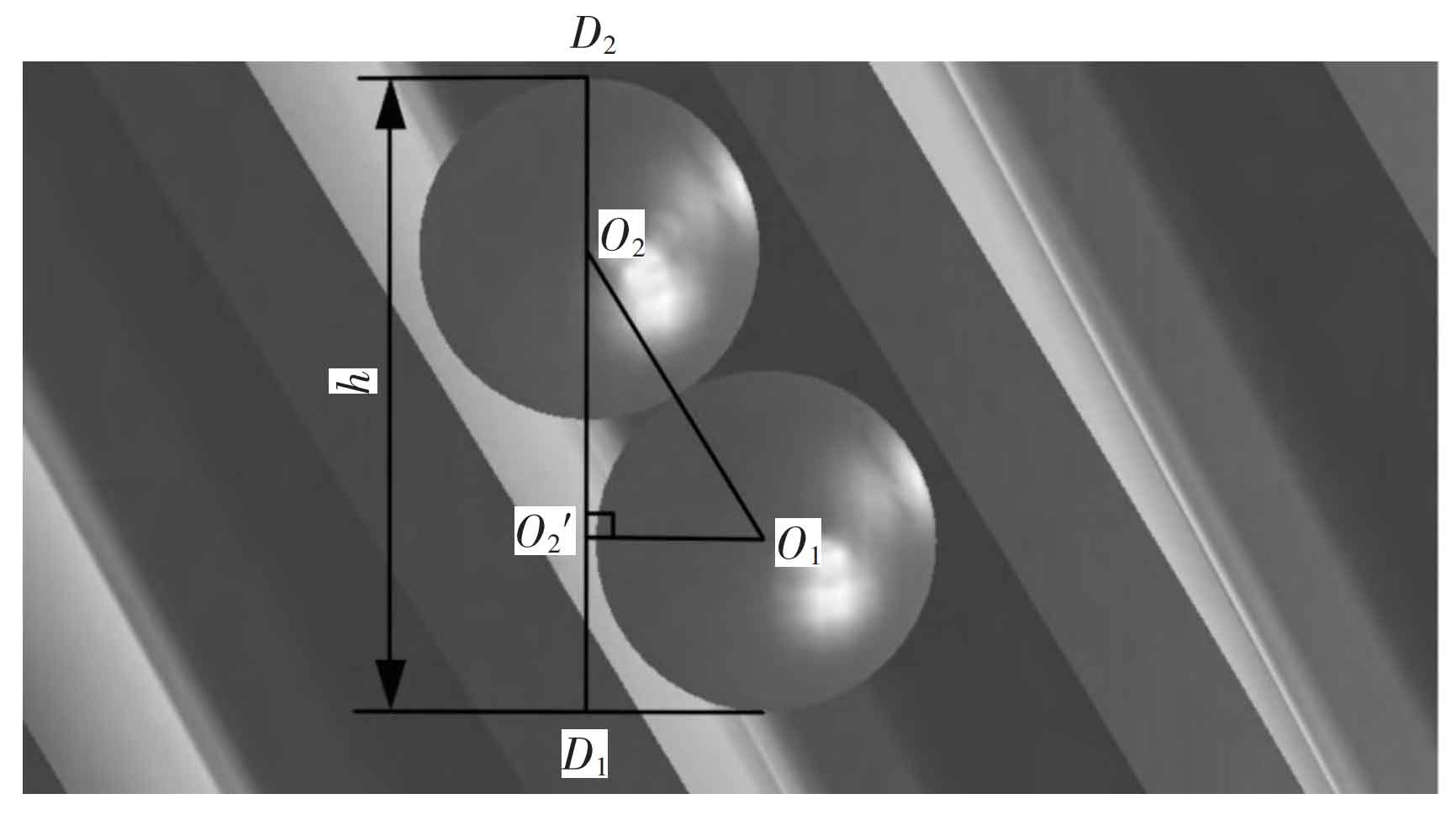

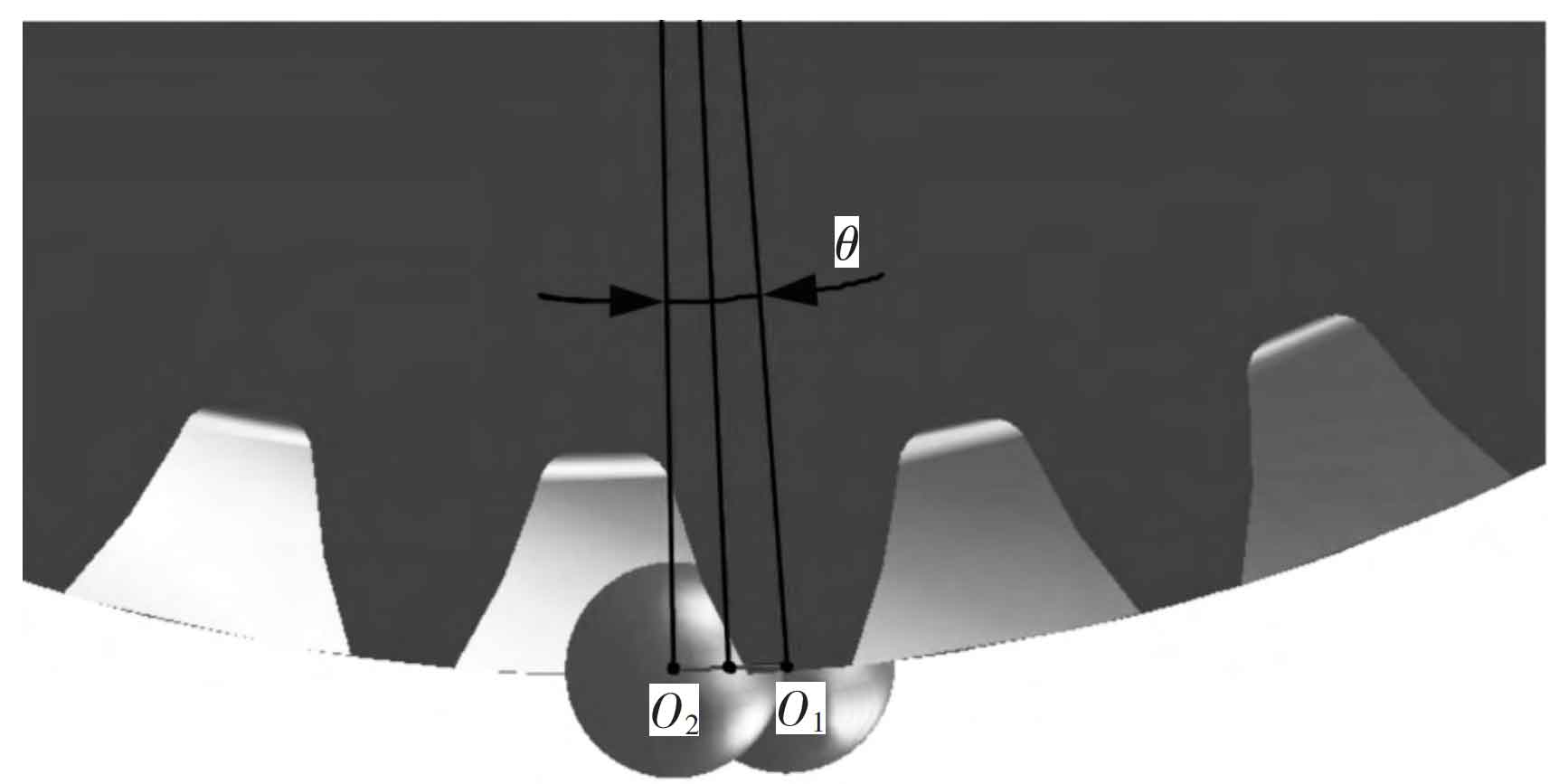

As shown in Figure 2 and figure 3, the distance of the steel ball along the axial direction of the helical cylindrical gear H = (n-1) o2o2 ‘+ DP, and the line segment o2o2’ = (h-dp) / (n-1) can be obtained by sorting. Where: H is the distance from the highest point of the nth steel ball; DP is the diameter of steel ball; O1 is the center of steel ball 1; O2 is the center of steel ball 2; O2 ‘is the projection point of O2 on the reference plane passing through O1.

When the helix angle of involute helical cylindrical gear β When the H value is small, the final calculation result is very sensitive to the measurement error of H value β When the angle is close to 30 °, the difference of measured H value is 0.01 mm, corresponding to β The difference of calculated angle is 30 ′~ 33 ′; If β The angle is too small, which is caused by the measurement error of H value β The deviation of angle calculation will be larger and even cannot be measured accurately.

Therefore, in order to reduce the measurement error of H value, multiple steel balls are used to measure H value in actual operation, and the measurement error of H value is evenly dispersed to reduce the measurement error of H value β Interference of angle calculation.