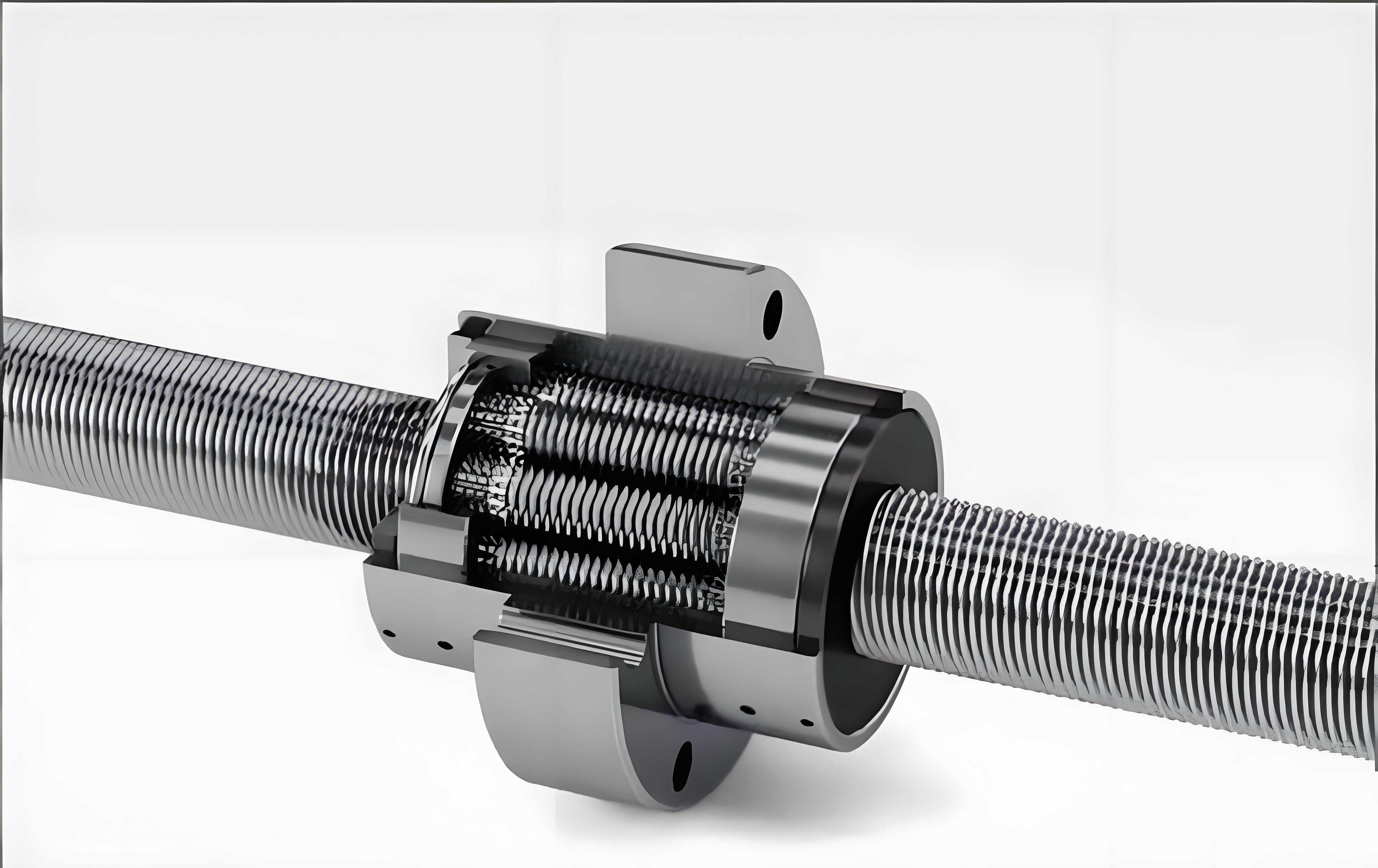

In this comprehensive study, I delve into the intricate meshing theory and contact characteristics of the recirculating planetary roller screw assembly. This mechanism is a precision transmission device that converts rotary motion into linear motion, renowned for its high load capacity, compact design, and longevity. The planetary roller screw assembly finds critical applications in aerospace, robotics, and high-precision machinery. My focus here is specifically on the recirculating variant, which features rollers without a helix angle, leading to unique engagement dynamics. Understanding the meshing behavior and contact stresses is paramount for optimizing the design and performance of the planetary roller screw assembly.

The recirculating planetary roller screw assembly comprises several key components: a screw, multiple rollers, a nut, a cage, and a cam ring. The screw and nut possess triangular thread profiles with single or multiple starts, while the rollers have annular grooves with a circular arc profile and no helical lead. This distinct architecture of the planetary roller screw assembly necessitates a dedicated analysis of its engagement principles. The rollers are housed in a cage that ensures even circumferential distribution, and the cam ring facilitates continuous motion by enabling roller recirculation. The fundamental kinematic relationship mandates that the screw, rollers, and nut share the same pitch, denoted as $P_S = P_R = P_N = P$. Furthermore, the number of starts on the screw and nut are equal ($n_S = n_N$), while the roller has zero starts ($n_R = 0$). The nominal radii satisfy the relation $r^N_n = r^S_n + r^R_n$, where $r^S_n$, $r^R_n$, and $r^N_n$ are the nominal radii of the screw, roller, and nut, respectively. The lead for the screw and nut are $L_S = 2\pi r^S_n \tan \lambda_S$ and $L_N = 2\pi r^N_n \tan \lambda_N$, with the roller lead $L_R = 0$ due to its zero helix angle ($\lambda_R = 0$).

To establish a mathematical model for the meshing behavior, I first define the coordinate systems. A global coordinate system $o-xyz$ is fixed in space, with the z-axis aligned with the screw axis. Local coordinate systems $o_S-x_S y_S z_S$, $o_R-x_R y_R z_R$, and $o_N-x_N y_N z_N$ are attached to the screw, roller, and nut, respectively, with their z-axes coinciding with the component axes. The thread profiles are defined in cross-sectional coordinates. For the screw and nut, the upper and lower helical raceway surfaces, denoted as $\Pi^T_i$ and $\Pi^B_i$ (where $i = S, N$), can be described by parametric equations. For the roller, the groove profile is circular. The position vector for a point on the helical surface of each component in the global system is derived as follows.

For the screw’s upper surface $\Pi^T_S$ and lower surface $\Pi^B_S$:

$$

\mathbf{r}_S^{T/B}(u_S, \theta_S) = \begin{bmatrix}

(u_S + r^S_n) \cos \theta_S \\

(u_S + r^S_n) \sin \theta_S \\

(c_S – \xi u_S \tan \beta_S) + \frac{L_S \theta_S}{2\pi}

\end{bmatrix}

$$

For the roller’s upper groove surface $\Pi^T_R$ and lower surface $\Pi^B_R$:

$$

\mathbf{r}_R^{T/B}(u_R, \theta_R) = \begin{bmatrix}

(u_R + r^R_n) \cos \theta_R \\

(u_R + r^R_n) \sin \theta_R \\

w_{PR} + \xi \sqrt{r_{PR}^2 – (u_R – u_{PR})^2}

\end{bmatrix}

$$

For the nut’s upper surface $\Pi^T_N$ and lower surface $\Pi^B_N$:

$$

\mathbf{r}_N^{T/B}(u_N, \theta_N) = \begin{bmatrix}

(u_N + r^N_n) \cos \theta_N \\

(u_N + r^N_n) \sin \theta_N \\

(c_N + \xi u_N \tan \beta_N) + \frac{L_N \theta_N}{2\pi}

\end{bmatrix}

$$

In these equations, $u_i$ is the profile parameter ranging from the root to the crest, $\theta_i$ is the angular coordinate, $\xi = +1$ for the upper surface and $\xi = -1$ for the lower surface, $\beta_i$ is the flank angle, $c_i$ is the half-thread thickness, $L_i$ is the lead, and for the roller, $r_{PR}$ is the radius of the circular arc profile with center coordinates $(u_{PR}, w_{PR})$ given by $u_{PR} = -r_{PR} \sin \beta_R$ and $w_{PR} = r_{PR} \cos \beta_R – c_R$.

The meshing mechanism of the planetary roller screw assembly is governed by the condition that two contacting surfaces remain tangent at their point of contact. Consider two general surfaces $\Pi_m$ and $\Pi_n$ that come into contact. When $\Pi_m$ is displaced along its axis by a vector $\mathbf{d}_{mn} = [0, 0, \delta_{mn}]^T$, it contacts $\Pi_n$ at a point. The tangency conditions require that the position vectors and the unit normal vectors coincide at the contact point. This yields the following system of equations:

$$

\mathbf{r}_n(u_n, \theta_n) = \mathbf{r}_m(u_m, \theta_m) + \mathbf{d}_{mn}

$$

$$

\mathbf{n}_m(u_m, \theta_m, \xi_m) = \mathbf{n}_n(u_n, \theta_n, \xi_n)

$$

From the component-wise equality, we derive four equations involving the four unknowns $u_m$, $\theta_m$, $u_n$, $\theta_n$:

$$

f_t(u_m, \theta_m, u_n, \theta_n) = 0, \quad t = 1,2,3,4

$$

Solving this system determines the meshing point coordinates. The axial clearance $\delta_{mn}$ is then obtained from the z-component equality. The clearance can be positive (gap), zero (perfect contact), or negative (interference).

For the planetary roller screw assembly, specific meshing occurs between the screw and roller, and between the roller and nut. I define the meshing point projections on the x-y plane. For the screw-roller interface, let $r_{CS}$ and $\phi_{CS}$ be the meshing radius and meshing deviation angle for the screw, and $r^S_{CR}$ and $\phi^S_{CR}$ for the roller on the screw side. They satisfy $r_{CS} = r^S_n + u_S$ and $r^S_{CR} = r^R_n + u_R$. The meshing equations are derived by equating the normal vectors of the contacting surfaces, say the screw’s upper surface $\Pi^T_S$ and the roller’s lower surface $\Pi^B_R$:

$$

\begin{aligned}

r_{CS} \sin \phi_{CS} &= r^S_{CR} \sin \phi^S_{CR} \\

r_{CS} \cos \phi_{CS} + r^S_{CR} \cos \phi^S_{CR} &= r^S_n + r^R_n \\

\sin \phi_{CS} \tan \lambda_{CS} + \cos \phi_{CS} \tan \beta_S &= \cos \phi^S_{CR} \tan \beta^S_{CR} \\

\cos \phi_{CS} \tan \beta_S – \sin \phi_{CS} \tan \lambda_{CS} &= \sin \phi^S_{CR} \tan \beta^S_{CR}

\end{aligned}

$$

Here, $\lambda_{CS} = \arctan(L_S / (2\pi r_{CS}))$ is the lead angle at the screw meshing radius, and $\beta^S_{CR}$ is the effective flank angle of the roller at the screw-side contact point, given by:

$$

\tan \beta^S_{CR} = \frac{r^R_n – r_{PR} \sin \beta_R + r^S_{CR}}{\sqrt{r_{PR}^2 – (r^S_{CR} – r_{PR} \sin \beta_R)^2}}

$$

The axial clearance for this screw-roller pair, $\delta_{SRT}$, is calculated as:

$$

\delta_{SRT} = \frac{P}{2} – (c_S + c_R) + \Delta_{SRT}

$$

$$

\Delta_{SRT} = r_{PR} \cos \beta_R – (r_{CS} – r^S_n) \tan \beta_S – \frac{\sqrt{r_{PR}^2 – (r^S_{CR} – r_{PR} \sin \beta_R)^2}}{2\pi} + \frac{L_S \phi_{CS}}{2\pi}

$$

Similarly, for the roller-nut interface, with meshing radius $r_{CN}$ and deviation angle $\phi_{CN}$ for the nut, and $r^N_{CR}$, $\phi^N_{CR}$ for the roller on the nut side, the meshing equations for contact between the roller’s upper surface $\Pi^T_R$ and the nut’s lower surface $\Pi^B_N$ are:

$$

\begin{aligned}

r_{CN} \sin \phi_{CN} &= r^N_{CR} \sin \phi^N_{CR} \\

r_{CN} \cos \phi_{CN} + r^N_{CR} \cos \phi^N_{CR} &= r^S_n + r^R_n \\

\sin \phi_{CN} \tan \lambda_{CN} + \cos \phi_{CN} \tan \beta_N &= \cos \phi^N_{CR} \tan \beta^N_{CR} \\

\sin \phi_{CN} \tan \beta_N – \cos \phi_{CN} \tan \lambda_{CN} &= \sin \phi^N_{CR} \tan \beta^N_{CR}

\end{aligned}

$$

where $\lambda_{CN} = \arctan(L_N / (2\pi r_{CN}))$, and $\beta^N_{CR}$ is defined analogously. The axial clearance $\delta_{NRT}$ is:

$$

\delta_{NRT} = \frac{P}{2} – (c_R + c_N) + \Delta_{NRT}

$$

$$

\Delta_{NRT} = r_{PR} \cos \beta_R – (r_{CN} – r^N_n) \tan \beta_N – \frac{\sqrt{r_{PR}^2 – (r^N_{CR} – r_{PR} \sin \beta_R)^2}}{2\pi} + \frac{L_N \phi_{CN}}{2\pi}

$$

The total axial clearance for each interface is the sum for both directions of motion. A key observation is that when the roller and nut flank angles are equal ($\beta_R = \beta_N$), the meshing point on the roller-nut side lies at the tangent point of their pitch diameters, i.e., $\phi_{CN} = \phi^N_{CR} = 0$, $r_{CN} = r^N_n$, and $r^N_{CR} = r^R_n$.

To evaluate the contact characteristics, I proceed to compute the principal curvatures at the meshing points, which are essential for Hertzian contact analysis. For a helical surface defined by $\mathbf{r}^{T/B}_i(u_i, \theta_i)$, the first and second fundamental forms are derived. Let $\mathbf{r}_u$ and $\mathbf{r}_{uu}$ denote the first and second partial derivatives with respect to $u$. The coefficients of the first fundamental form are:

$$

E = \mathbf{r}_u \cdot \mathbf{r}_u, \quad F = \mathbf{r}_u \cdot \mathbf{r}_\theta, \quad G = \mathbf{r}_\theta \cdot \mathbf{r}_\theta

$$

The coefficients of the second fundamental form are:

$$

L = \mathbf{r}_{uu} \cdot \mathbf{n}, \quad M = \mathbf{r}_{u\theta} \cdot \mathbf{n}, \quad N = \mathbf{r}_{\theta\theta} \cdot \mathbf{n}

$$

where $\mathbf{n}$ is the unit normal vector. The Gaussian curvature $K$ and mean curvature $H$ are:

$$

K = \frac{LN – M^2}{EG – F^2}, \quad H = \frac{EN – 2FM + GL}{2(EG – F^2)}

$$

The principal curvatures $\kappa_1$ and $\kappa_2$ are then:

$$

\kappa_1 = H + \sqrt{H^2 – K}, \quad \kappa_2 = H – \sqrt{H^2 – K}

$$

For the planetary roller screw assembly components, these curvatures are evaluated at the meshing points. Subsequently, applying Hertzian contact theory, the contact between the roller and the raceways is modeled as an elliptical contact patch. Define the principal curvatures for body I (e.g., roller) as $\kappa_1^I$, $\kappa_2^I$ and for body II (e.g., screw or nut) as $\kappa_1^{II}$, $\kappa_2^{II}$. The curvature sum and difference are:

$$

\rho_\Sigma = \kappa_1^I + \kappa_2^I + \kappa_1^{II} + \kappa_2^{II}

$$

$$

F(\rho) = \frac{|(\kappa_1^I – \kappa_2^I) + (\kappa_1^{II} – \kappa_2^{II})|}{\rho_\Sigma}

$$

Under a normal load $Q$, the semi-major axis $a$ and semi-minor axis $b$ of the contact ellipse are:

$$

a = a_m \sqrt[3]{\frac{3Q}{2\rho_\Sigma} \left( \frac{1-\nu_1^2}{E_1} + \frac{1-\nu_2^2}{E_2} \right) }

$$

$$

b = b_m \sqrt[3]{\frac{3Q}{2\rho_\Sigma} \left( \frac{1-\nu_1^2}{E_1} + \frac{1-\nu_2^2}{E_2} \right) }

$$

where $a_m$ and $b_m$ are coefficients depending on the ellipticity parameter, $E_1$, $E_2$ are elastic moduli, and $\nu_1$, $\nu_2$ are Poisson’s ratios. The maximum contact stress at the ellipse center is:

$$

\sigma_{max} = \frac{3Q}{2\pi ab}

$$

To illustrate the meshing and contact behavior, I perform numerical analyses based on typical parameters for a planetary roller screw assembly. The following table lists the basic geometric parameters used in the calculation.

| Parameter | Screw | Roller | Nut |

|---|---|---|---|

| Nominal radius $r_n^i$ (mm) | 15 | 5 | 25 |

| Flank angle $\beta_i$ (°) | 45 | 45 | 45 |

| Crest height $a_i$ (mm) | 0.4 | 0.4 | 0.4 |

| Root height $b_i$ (mm) | 0.55 | 0.55 | 0.55 |

| Half-thickness $c_i$ (mm) | 0.44 | 0.47 | 0.52 |

| Number of starts $n_i$ | 2 | 0 | 2 |

| Pitch $P$ (mm) | 2 | 2 | 2 |

| Groove arc radius $r_{PR}$ (mm) | — | 7.07 | — |

Solving the meshing equations yields the following results for the meshing point locations and axial clearances in this planetary roller screw assembly.

| Meshing Parameter | Screw-Roller Side | Roller-Nut Side |

|---|---|---|

| Meshing radius (mm) | $r_{CS}=15.001$, $r^S_{CR}=5.002$ | $r_{CN}=25.000$, $r^N_{CR}=5.000$ |

| Meshing deviation angle (°) | $\phi_{CS}=0.608$, $\phi^S_{CR}=1.822$ | $\phi_{CN}=0.000$, $\phi^N_{CR}=0.000$ |

| Axial clearance $\delta$ (mm) | 0.173 | 0.020 |

The results confirm that for the screw-roller interface, the meshing point deviates from the line connecting the screw and roller axes, with the point located slightly toward the thread crest. For the roller-nut interface with equal flank angles, the meshing occurs precisely at the pitch diameter tangent point. Importantly, the deviation angles and the differences between meshing and nominal radii are small for this planetary roller screw assembly, implying that in approximate calculations, nominal radii can be used instead of meshing radii.

I further investigate the influence of the flank angle and pitch on the meshing position and axial clearance. For the screw-roller side, varying the flank angle from 30° to 60° shows that as the flank angle increases, the meshing point shifts closer to the line connecting the screw and roller axes. The axial clearance increases only marginally, from 0.1683 mm at 30° to 0.1761 mm at 60°, indicating low sensitivity. This behavior is beneficial for reducing sliding friction in the planetary roller screw assembly. Next, examining the effect of pitch (from 0.25 mm to 3 mm, while keeping other profile parameters constant) reveals that with increasing pitch, the meshing point moves farther away from the axis connecting line, and the axial clearance increases. Notably, for pitches below 2 mm, the clearance becomes negative (interference), which would hinder operation. Therefore, selecting an appropriate pitch is crucial for ensuring proper clearance and smooth functioning of the planetary roller screw assembly.

Now, turning to contact characteristics, I compute the principal curvatures using both the exact meshing radii and the nominal radii as an approximation. The material is bearing steel GCr15 with elastic modulus $E = 2.12 \times 10^5$ MPa and Poisson’s ratio $\nu = 0.29$. A normal load of $Q = 200$ N per thread tooth is applied. The calculated principal curvatures are summarized below.

| Component & Surface | Principal Curvature $\kappa_1$ (mm⁻¹) | Principal Curvature $\kappa_2$ (mm⁻¹) |

|---|---|---|

| Screw (exact) | 0.0472 | -4.2323 × 10⁻⁵ |

| Screw (approx. with $r_n^S$) | 0.0472 | -4.2314 × 10⁻⁵ |

| Roller on screw side (exact) | 0.1353 | 0.1481 |

| Roller on screw side (approx.) | 0.1352 | 0.1480 |

| Roller on nut side (exact) | 0.1353 | 0.1481 |

| Roller on nut side (approx.) | 0.1352 | 0.1480 |

| Nut (exact) | -0.0283 | 9.1602 × 10⁻⁶ |

| Nut (approx. with $r_n^N$) | -0.0283 | 9.1602 × 10⁻⁶ |

The close agreement validates that using nominal radii for curvature estimation is acceptable for this planetary roller screw assembly in many practical scenarios.

The impact of flank angle on contact parameters is significant. As the flank angle increases from 30° to 60°, the curvature difference $F(\rho)$ decreases for both the screw-roller and roller-nut interfaces, meaning the contact ellipse becomes more circular. The contact area, proportional to $a \times b$, also decreases with increasing flank angle. Consequently, the maximum contact stress $\sigma_{max}$ increases. For instance, at a 30° flank angle, $\sigma_{max}$ might be around 1500 MPa, while at 60°, it could exceed 2000 MPa for the given load. This suggests that excessively large flank angles should be avoided in the design of a planetary roller screw assembly to prevent high contact stresses that could lead to plastic deformation or reduced fatigue life.

Varying the pitch from 0.25 mm to 3 mm shows that the curvature difference increases with pitch, indicating a more elliptical contact patch. However, the contact area and maximum contact stress remain relatively insensitive to pitch changes. The contact area on the roller-nut side is generally larger than that on the screw-roller side due to differences in curvature sums, while the contact stress is higher on the roller-nut side. This nuanced behavior must be accounted for in the load distribution analysis of a multi-roller planetary roller screw assembly.

In conclusion, this detailed investigation into the recirculating planetary roller screw assembly has elucidated its unique meshing mechanism and contact characteristics. The mathematical models for helical surfaces, meshing conditions, and Hertzian contact provide a robust framework for analysis. Key findings include: the screw-roller meshing point always deviates from the axis connecting line; when roller and nut flank angles match, meshing occurs at the pitch diameter tangent; nominal radii can approximate meshing radii for curvature calculations; increasing flank angle reduces curvature difference and contact area but raises contact stress; pitch variation mainly affects curvature difference with minimal impact on stress and area. Therefore, for optimal design of a planetary roller screw assembly, moderate flank angles and appropriate pitch selection are recommended to balance load capacity, wear resistance, and manufacturing feasibility. Further research could explore the effects of load distribution among multiple rollers and dynamic lubrication conditions in this complex yet vital mechanical system.