Compared with the straight bevel gear, the spiral bevel gear will increase the overlap between the teeth when meshing. Therefore, the motion transmission will be smoother than straight bevel gear or helical bevel gear, so that they can effectively reduce the noise and vibration at high speed. At the same time, it has the advantages of high load capacity and high transmission efficiency, and is widely used in automobiles, aircraft, machine tools and other machinery. The noise, vibration and durability level are usually mainly affected by the contact mode and transmission error. The error factors in the transmission process include the quasi-conjugation characteristics, deformation, manufacturing error, installation error, etc. of spiral bevel gears. They have an important influence on the dynamic performance, tooth contact quality and vibration noise of spiral bevel gear transmission. The installation error is an unavoidable human factor, which will directly change the contact mode of the gear teeth and affect the transmission performance of the gear. At the beginning, the geometric algorithm and simulation generation of spiral bevel gear meshing contact with bearing were studied, a method called “local synthesis” was proposed, and a pre-designed parabolic function with limit transmission error was designed and provided, which can control the linear function of transmission error caused by installation error, reduce the vibration level, eliminate the transmission error caused by installation error, and reduce the impact during transmission Vibration and noise.

This method is the basic theoretical method to study the transmission error and meshing performance of spiral bevel gears. Subsequently, Gleason proposed tooth contact analysis (TCA), which simulates the meshing and contact of two tooth surfaces in local contact. Through the tooth contact analysis, the contact trace of the tooth surface, the transmission error caused by the installation error and the contact trace formed by the instantaneous contact ellipse are determined. The shape, size and position of the contact area of the tooth surface are simulated in advance on the computer, and reasonable correction parameters can be obtained, Then, these machine tool adjustment parameters that make the contact area of the tooth surface reasonable are used to guide the gear processing and production process, thus effectively shortening the production cycle of spiral bevel gears. On the basis of the theory of (Tooth Contact Analysis, TCA), researchers have put forward the theory of Load Tooth Contact Analysis (LTCA), the method of Tooth Con ‐ act Finite Element Analysis (TCFEA) and the method of Error Tooth Contact Analysis (ETCA) with installation errors.

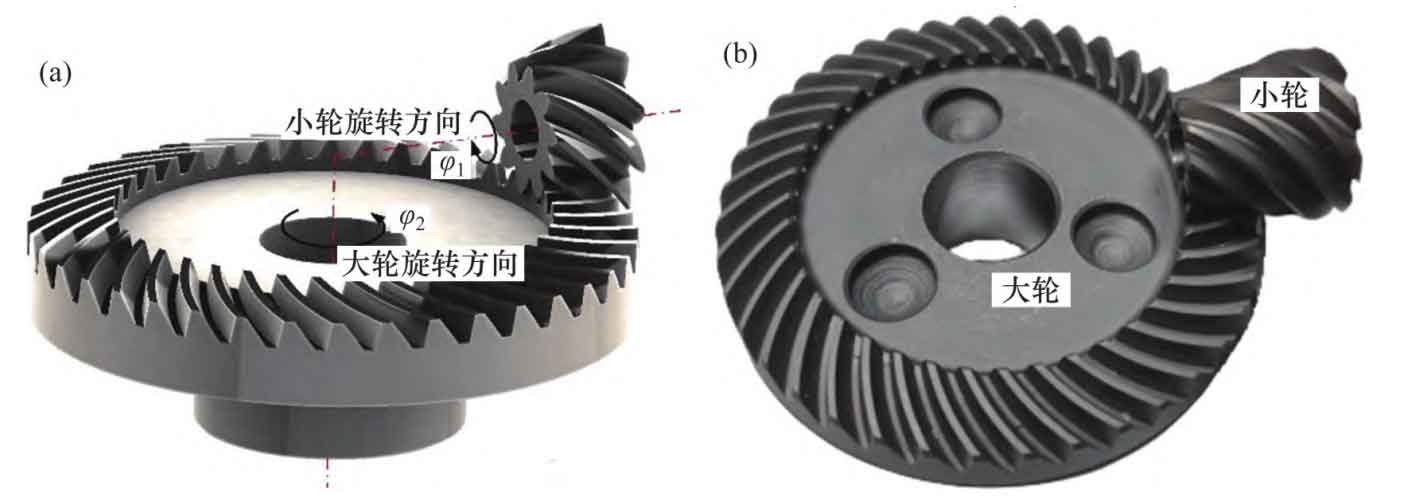

In recent years, gear researchers mainly focus on spiral bevel gears with high contact performance without edge contact, concentrated stress and reasonable transmission error. Therefore, optimizing the more reasonable meshing area to improve the meshing performance of spiral bevel gear has become the main research direction of scholars studying spiral bevel gear transmission. In this paper, the four existing forms of installation error are fully considered, and the three-dimensional model of spiral bevel gear with installation error is established, and the finite element software is used for analysis, and the gear meshing performance under static and dynamic conditions is obtained respectively. Through comparison, the comprehensive influence of installation error and load on gear meshing performance is finally obtained.